Treatment method of high strength corrosion resistant steel pipe

A treatment method and anti-corrosion technology, applied in metal material coating process, fusion spraying, coating, etc., can solve the problems of restricting the application of steel pipes, improve application ability, simple and convenient treatment method, improve surface strength and durability The effect of corrosive ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

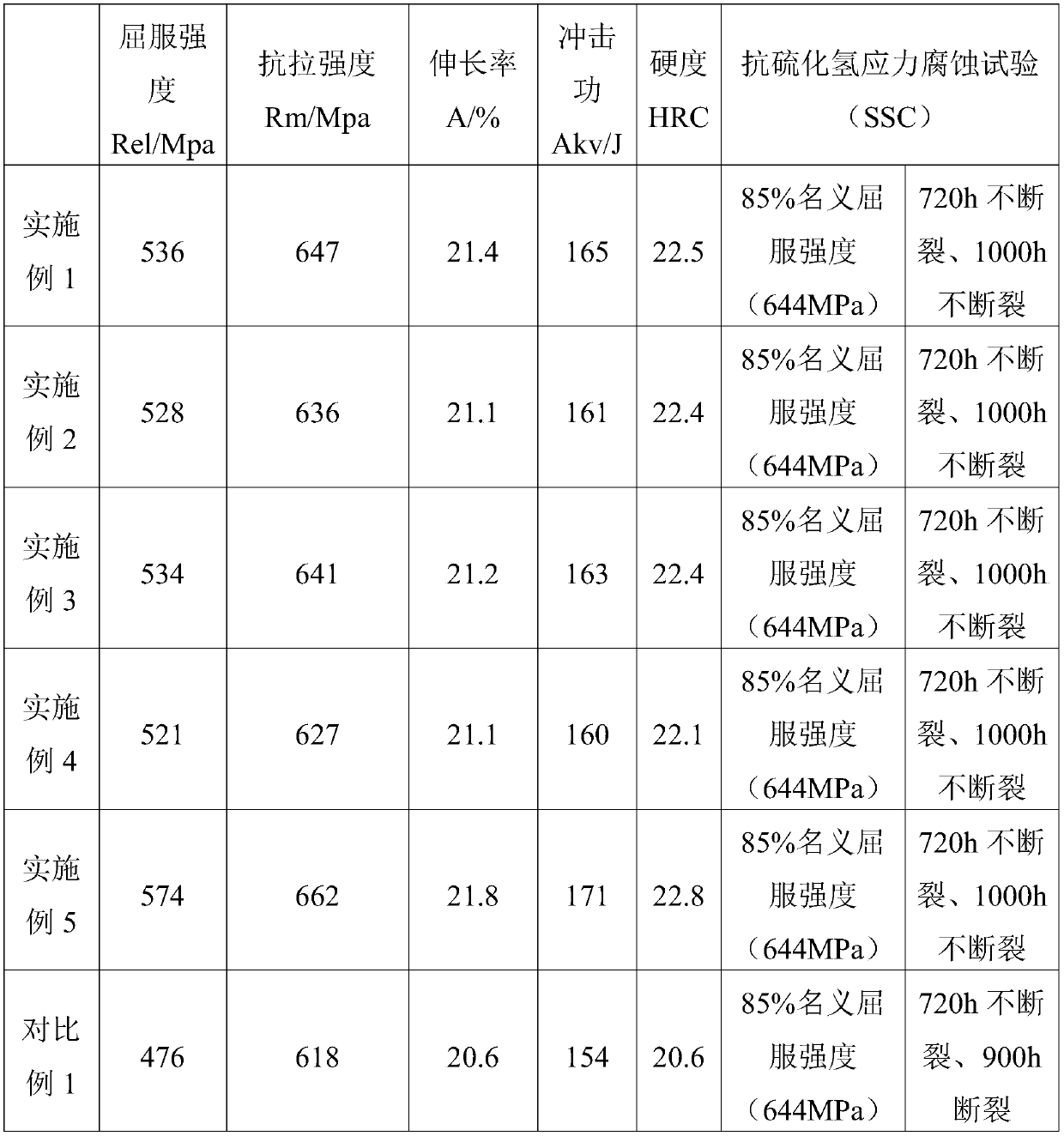

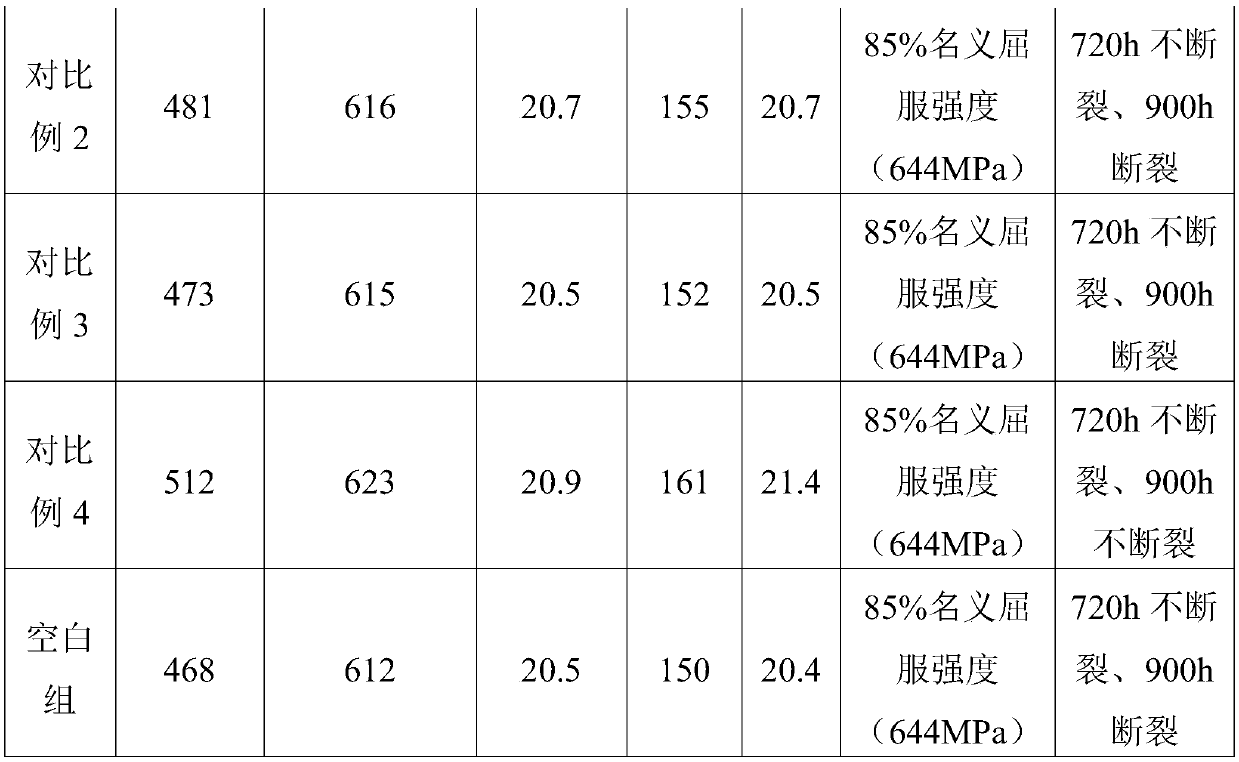

Examples

Embodiment 1

[0034] A steel pipe surface treatment method, comprising the following steps:

[0035] (1) Perform rapid temperature rise treatment on the surface of the steel pipe, including preheating the steel pipe so that the temperature reaches 220°C, then heat preservation treatment for 2 hours, and then heat up to 360°C at a speed of 20°C / min;

[0036] (2) Use a high-temperature spraying device to evenly spray the composite powder onto the surface of the steel pipe to form a build-up reinforcement layer;

[0037] Based on the total amount of composite powder, the weight percentage of each powder is: carbon powder 5%, manganese powder 8%, copper powder 2%, zinc powder 30%, and the rest is aluminum powder;

[0038] The average particle diameter of described carbon powder, aluminum powder, manganese powder, copper powder and zinc powder is 420nm;

[0039] Control the amount of spraying so that the thickness of the accumulation enhancement layer formed after spraying is 15 μm;

[0040] (...

Embodiment 2

[0042] As in the steel pipe surface treatment method provided in Example 1, the difference is that the composition of the composite powder used is different: based on the total amount of composite powder, the weight percentage of each powder is: carbon powder 3%, manganese 6% copper powder, 1% copper powder, 28% zinc powder, and the rest is aluminum powder;

[0043] The rest remain unchanged, and the treatment of the steel pipe is completed according to the treatment method provided in Example 1.

Embodiment 3

[0045] As in the steel pipe surface treatment method provided in Example 1, the difference is that the composition of the composite powder used is different: based on the total amount of the composite powder, the weight percentage of each powder is: carbon powder 7%, manganese 10% copper powder, 3% copper powder, 32% zinc powder, and the rest is aluminum powder;

[0046] The rest remain unchanged, and the treatment of the steel pipe is completed according to the treatment method provided in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com