Hydrolysis-resistant PU synthetic leather and production method thereof

A technology of hydrolysis resistance and production method, which is applied in the direction of textiles and papermaking, can solve the problems of unbalanced force, easy to be damaged, low adhesion, etc., to ensure balanced force, improve hydrolysis resistance, improve The effect of applying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

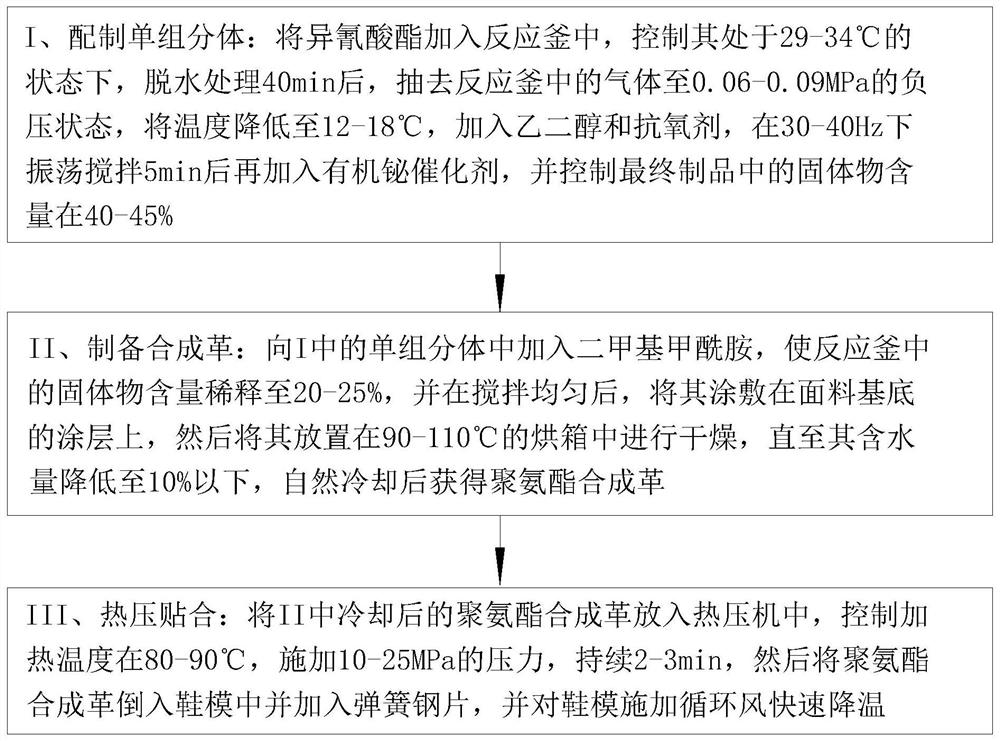

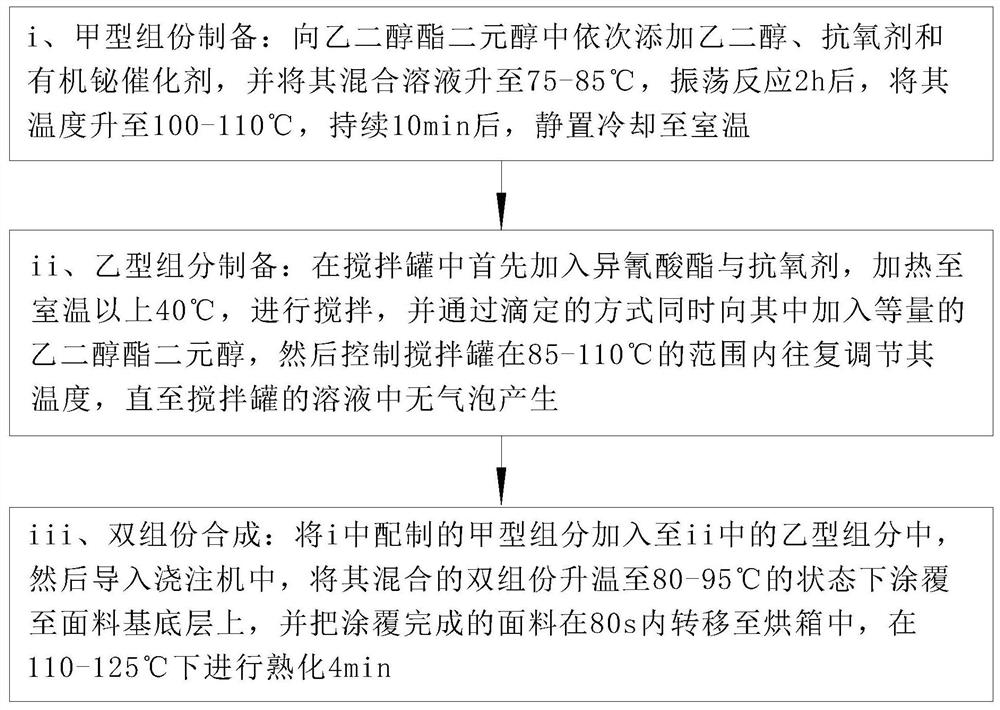

Method used

Image

Examples

Embodiment approach

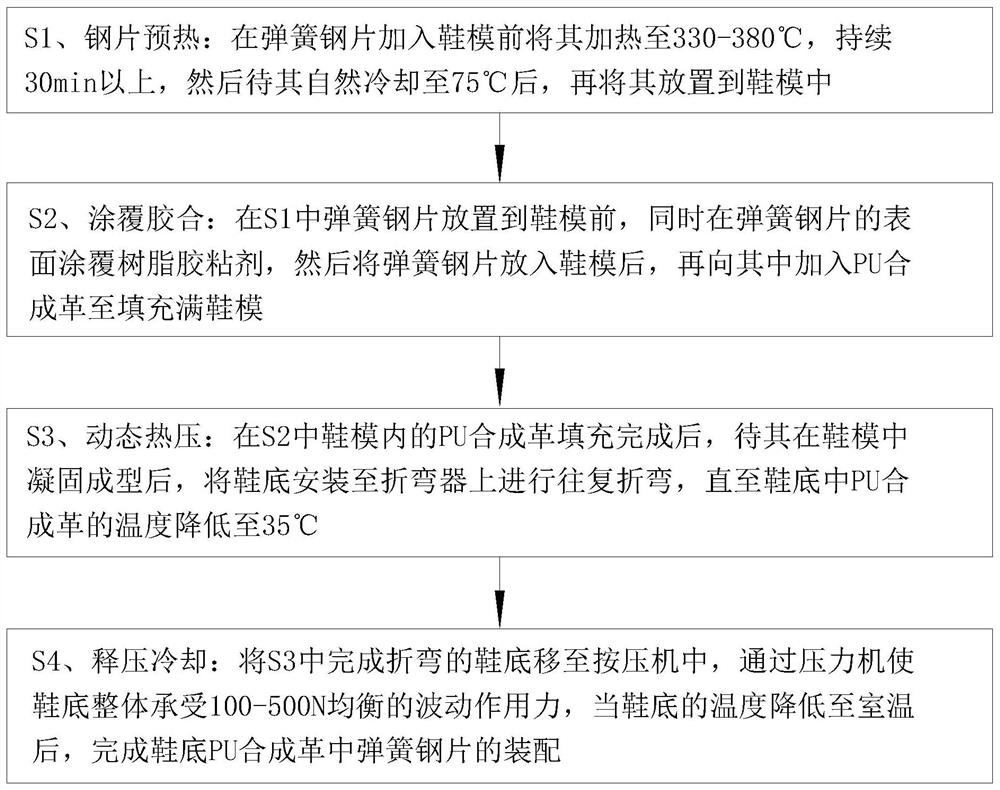

[0039] As an embodiment of the present invention, the steps of assembling the spring steel sheet into the sole PU synthetic leather material are as follows:

[0040] S1. Steel sheet preheating: before the spring steel sheet is added to the shoe mold, heat it to 330-380°C for more than 30 minutes, and then place it in the shoe mold after it is naturally cooled to 75°C; The heating and natural cooling of the steel sheet further dissipate the internal stress in the spring steel sheet, reducing the damage of the internal stress deformation of the spring steel sheet to the PU synthetic leather material in the sole;

[0041] S2. Coating and gluing: In S1, the spring steel sheet is placed before the shoe mold, and resin adhesive is coated on the surface of the spring steel sheet at the same time, and then the spring steel sheet is put into the shoe mold, and then PU synthetic leather is added to it until it is filled. Fill the shoe mold; use the plasticity of the resin adhesive after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com