Method and device for assisting construction of underwater open caisson

A caisson and water flow technology, applied in caissons, infrastructure engineering, construction, etc., can solve problems such as caisson tilting and endangering bridge construction safety, and achieve the effects of reducing water flow velocity, saving construction costs, and reducing tilt risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

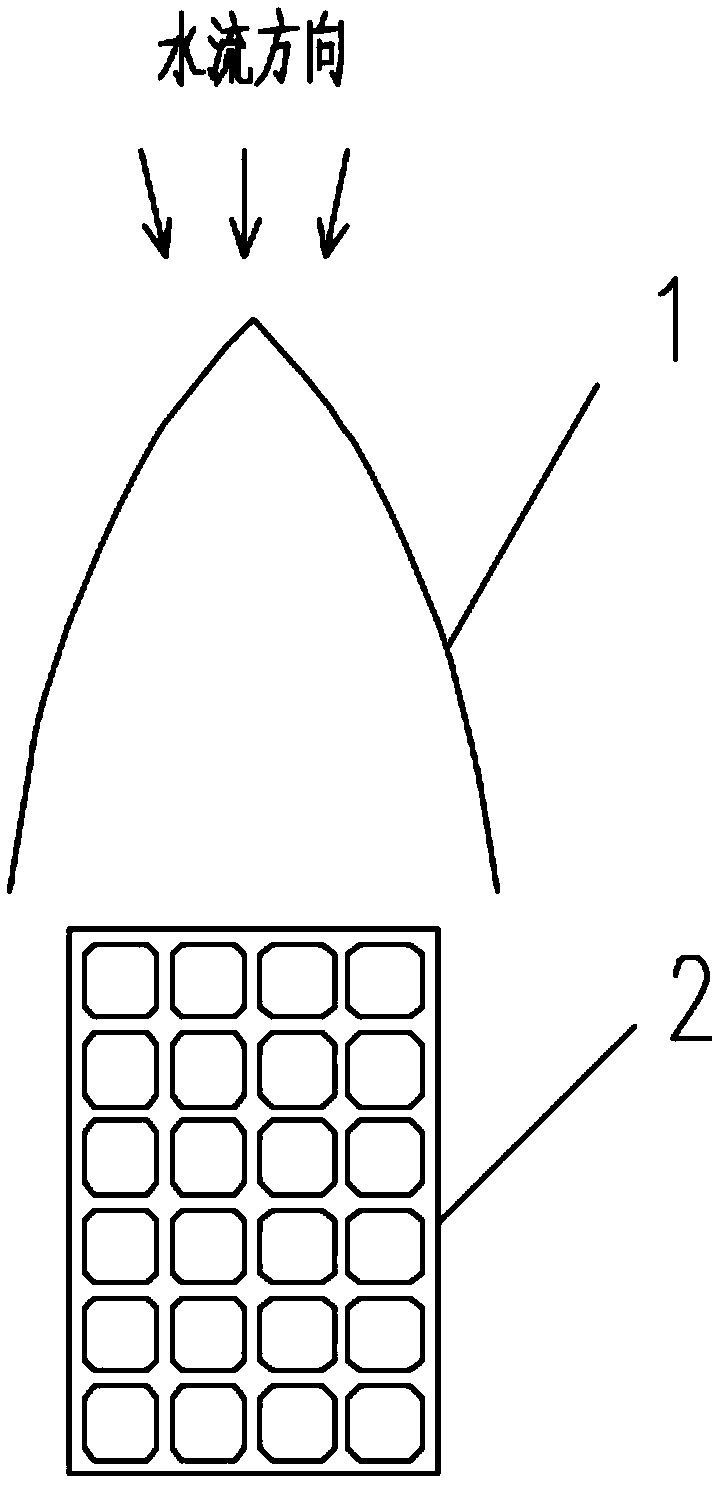

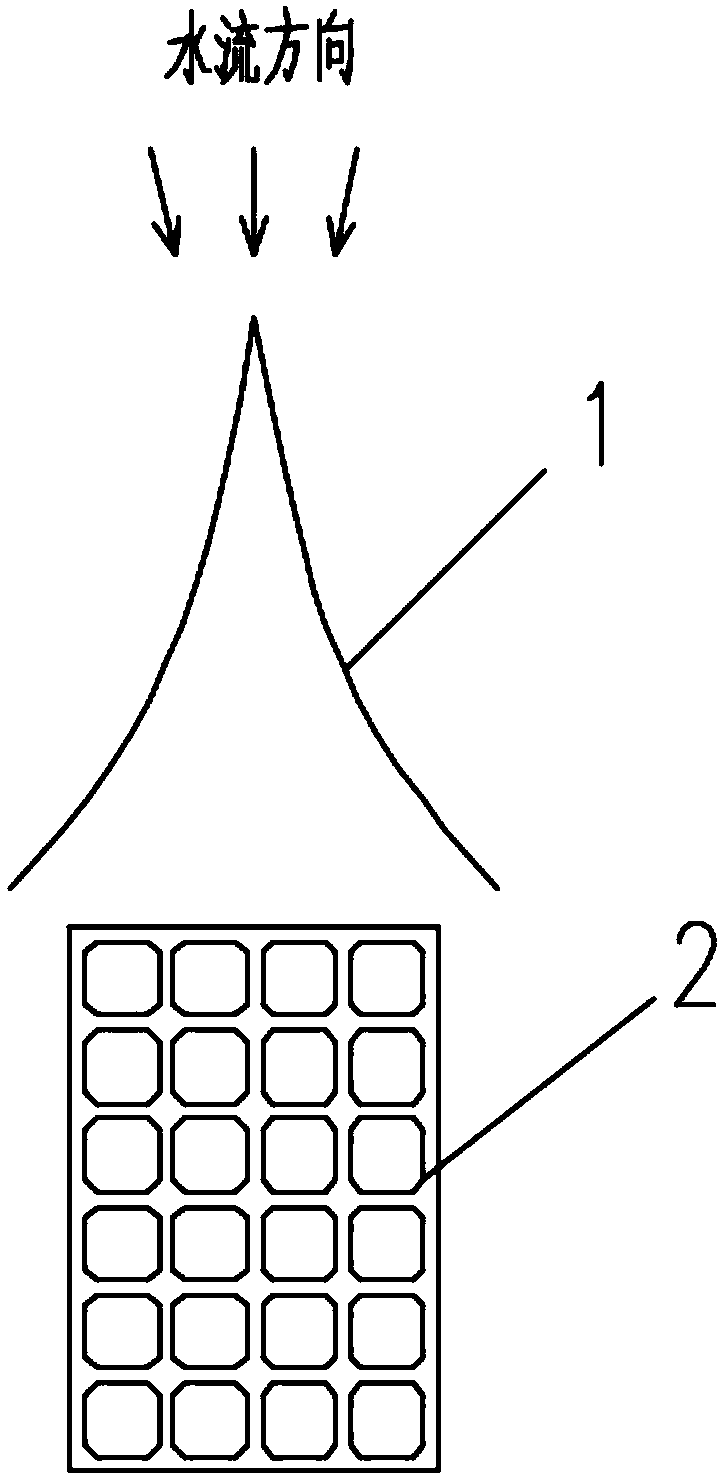

[0024] In this embodiment, a method for assisting the construction of caissons in water uses a diversion structure capable of diverting water to divert the water flow, and installs the caisson 3 behind the diversion structure.

[0025] Utilizing the diversion structure to divert the water flow can make the water flow along the outer surface of the diversion structure, and reduce the flow velocity of the water flow behind the diversion structure, and the caisson behind the diversion structure can reduce the impact on the caisson 3 during construction. The thrust of the water flow can reduce the resistance during the sinking process of the caisson 3, reduce the scale of the caisson positioning device, improve the construction efficiency and construction positioning accuracy, and significantly save the construction cost.

[0026] The cross-sectional area of the distribution structure gradually increases along the direction of water flow. In this way, the water flow can be made ...

Embodiment 2

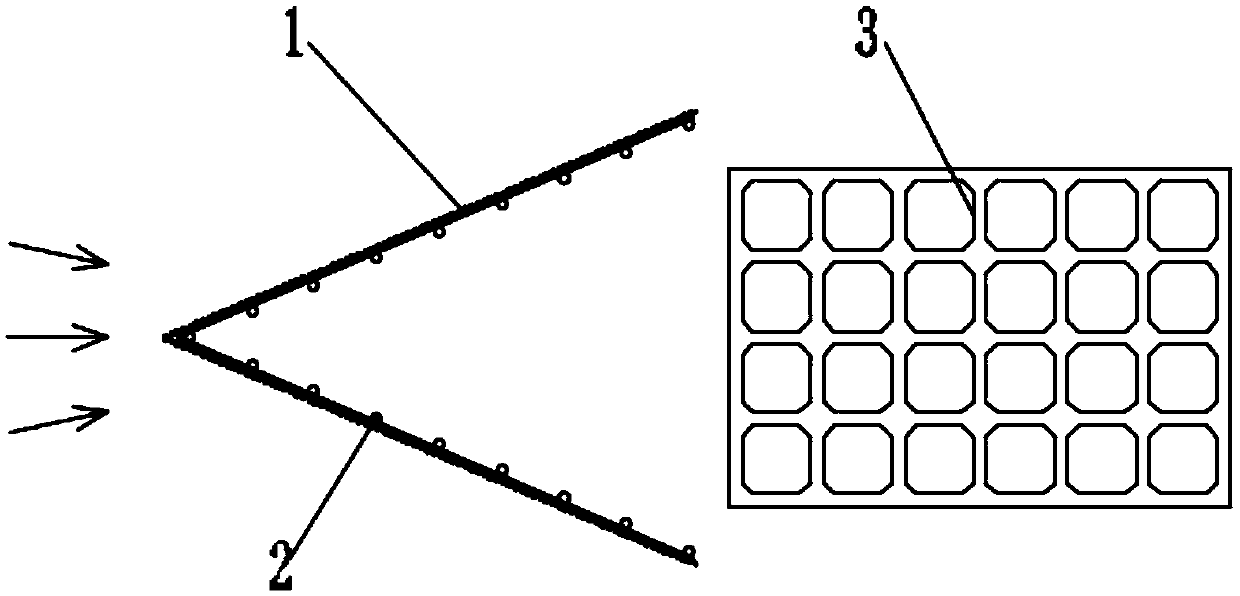

[0029] Such as figure 1 As shown, on the basis of the above embodiments, in this embodiment, two plate structures 1 are used to form a V-shaped structure to form a diversion structure, and the plate structures 1 are driven into the riverbed below. Combining the plate structure 1 to form a V shape has the advantages of simple structure, convenient use, quick operation, etc., and can quickly form an effective shunt structure. According to specific needs, the included angle of the V shape can be adjusted.

[0030] The smaller the included angle is, the smaller the included angle is, the smoother the water flow transition is, and the smaller the influence on the water flow is, the better the diversion effect is, and the longer the length of the plate-shaped structure 1 required to meet the conditions that can fully cover the range of the caisson 3 The longer, the more consumables, the greater the project volume, and the higher the cost.

[0031] The larger the included angle, th...

Embodiment 3

[0034] On the basis of the above embodiments, in this embodiment, the plate structure 1 adopts one of metal plates, steel sheet piles and steel sheet piles, and interlocking steel pipe piles and interlocking steel pipe piles. form.

[0035] The metal plate can be used to directly construct the diversion structure, just bury the metal plate deep in the river bed, or weld two metal plates into a V shape for construction, or use other connection methods to connect the two metal plates into a V The metal plate has the advantages of convenient construction, high strength and strong impact resistance. In order to meet the anti-corrosion performance, corrosion-resistant metal plates, such as aluminum alloy plates, stainless steel plates, etc., can be used. Reinforced concrete slabs can also be used.

[0036] To use steel sheet piles to connect steel sheet piles, it is necessary to sequentially drive multiple steel sheet piles into the river bed, and then make adjacent steel sheet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com