Construction method of super-long expansion head anchor cable of large deformation tunnel with high ground stress and weak surrounding rock

A technology of weak surrounding rock and high in-situ stress, applied in earth-moving drilling, installation of bolts, mining equipment, etc., can solve the problems of long in-situ stress release period, secondary lining cracking, shotcrete cracking, etc., and achieve significant economic benefits and savings Engineering materials, the effect of improving the stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

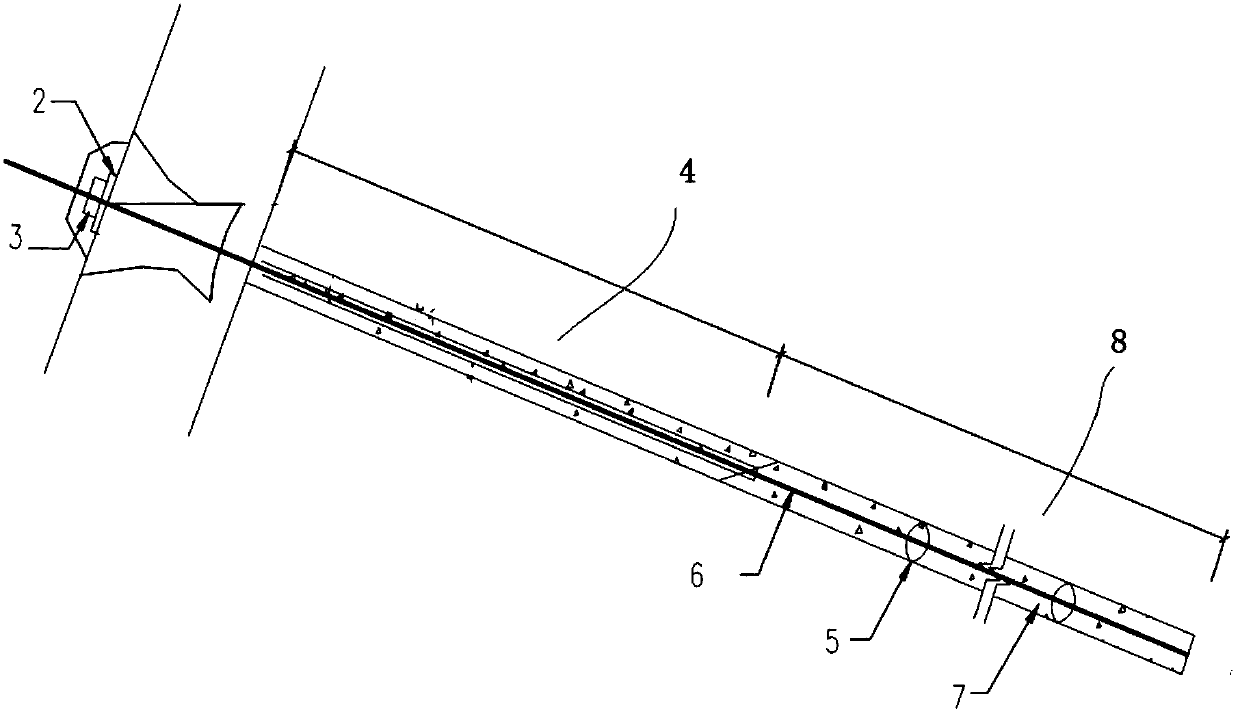

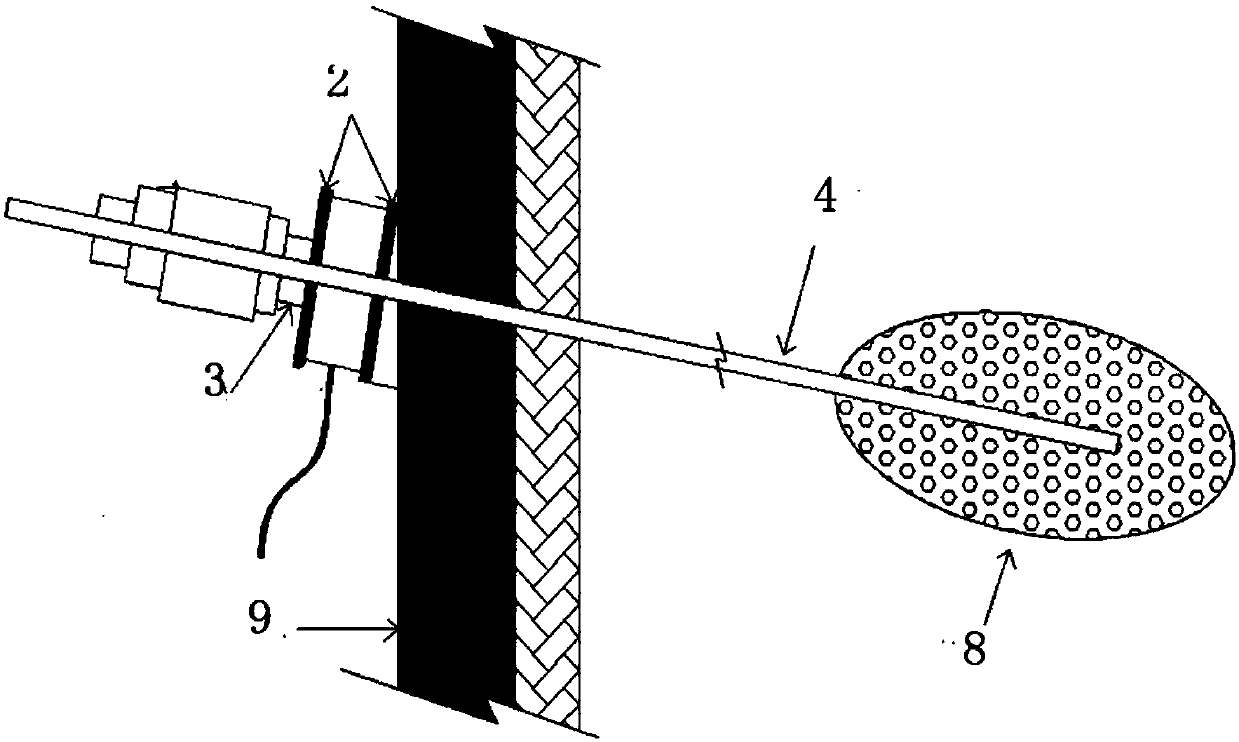

[0037] In order to enable those skilled in the art to better understand the present invention, the technical solutions of the present invention will be further described below with reference to the accompanying drawings and embodiments.

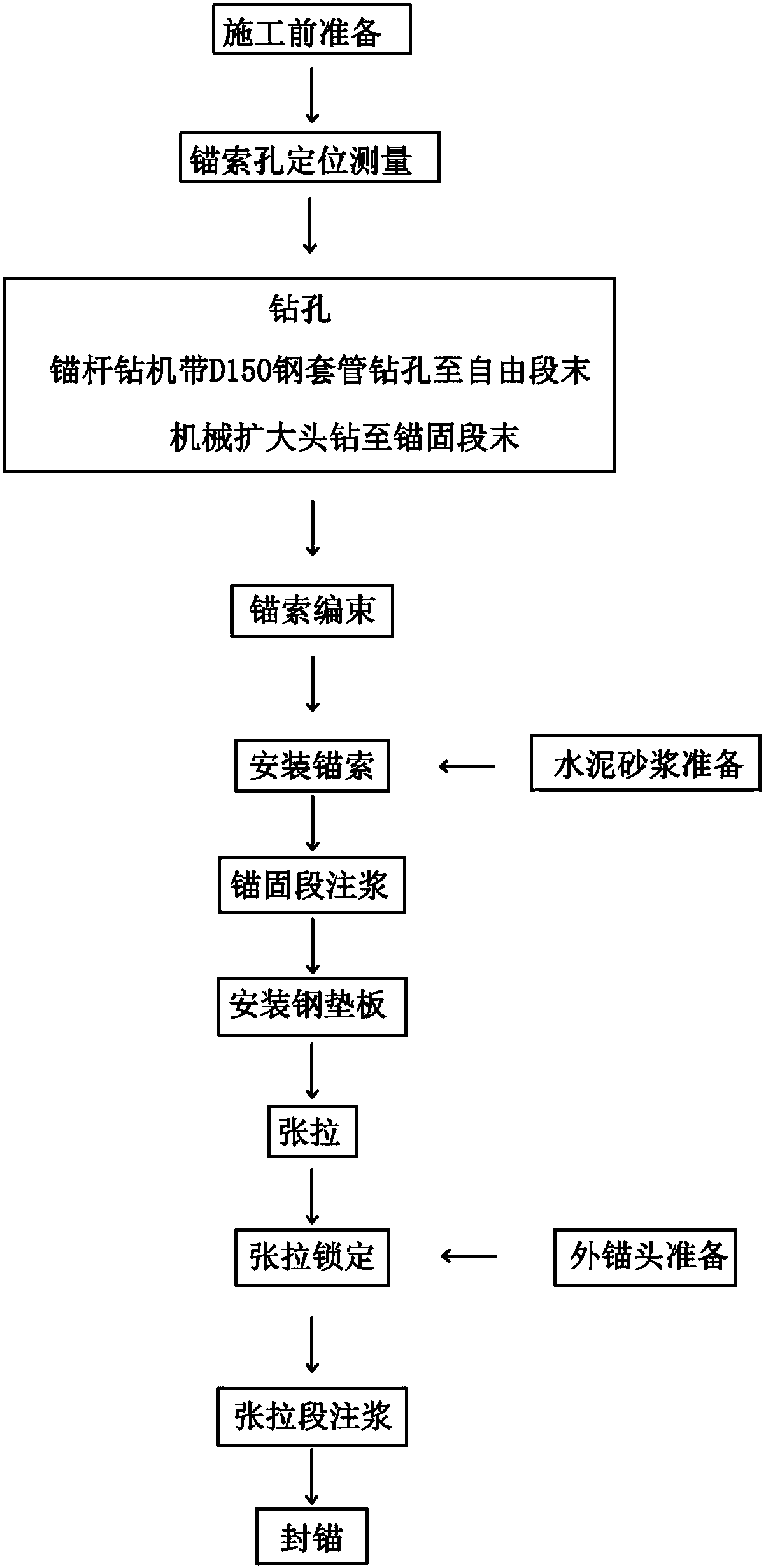

[0038] Such as figure 1 , figure 2 , image 3 As shown, the construction method of the super-long enlarged head anchor cable for the tunnel with high ground stress, weak surrounding rock and large deformation includes the following steps:

[0039] 1. Preparation before construction

[0040] (1) Carry out equipment matching, rationally organize labor, and purchase qualified construction materials;

[0041] (2) Calibrate the tension jack, high-pressure oil pump, and pressure gauge to ensure that they can meet the construction needs, and draw the pressure gauge reading-tension relationship curve to guide the on-site tensioning operation;

[0042] (3) Prepare enough materials according to the design quantity, and sample steel strands and anchors for mech...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com