Automatic furnace body feeding and discharging mechanism for silicon wafer production

A technology of automatic loading and unloading, transmission mechanism, applied in furnaces, crystal growth, furnace components, etc., to achieve the effect of high stability, high safety level, and reduced work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

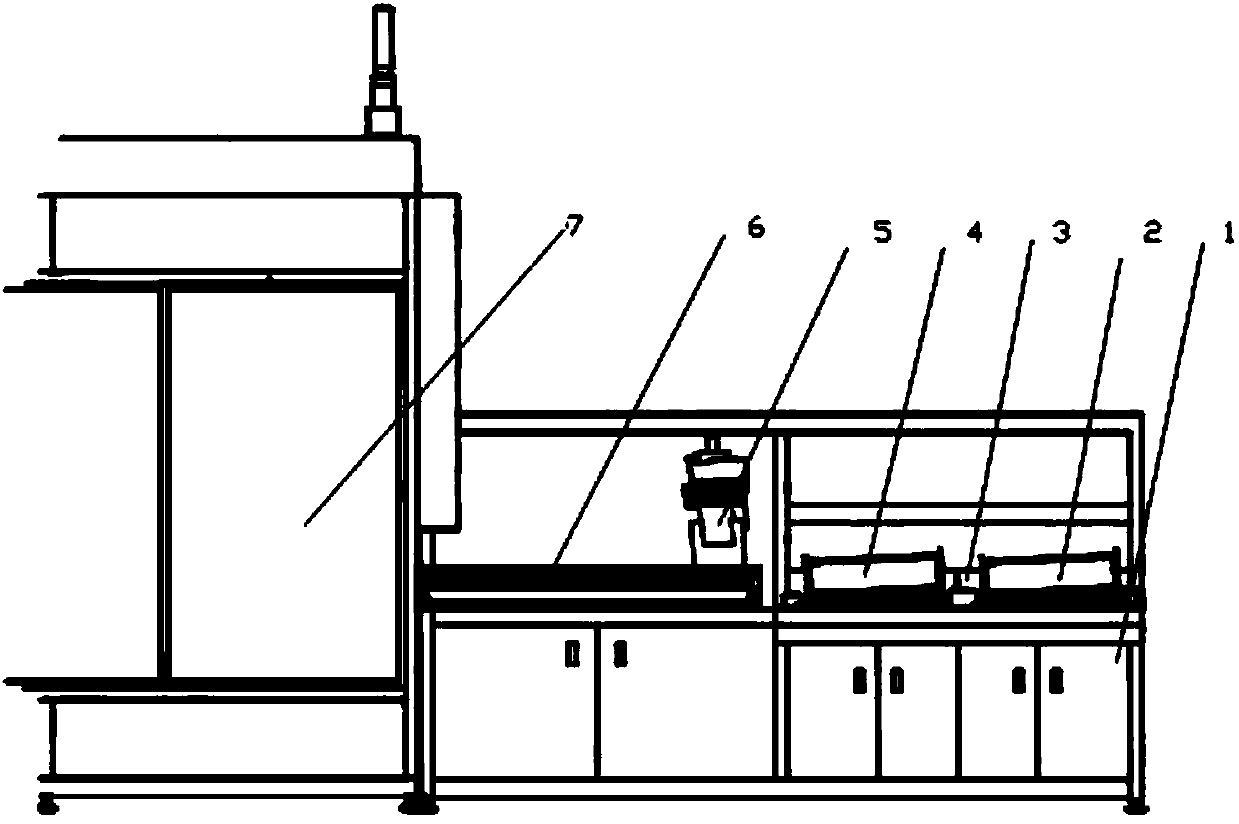

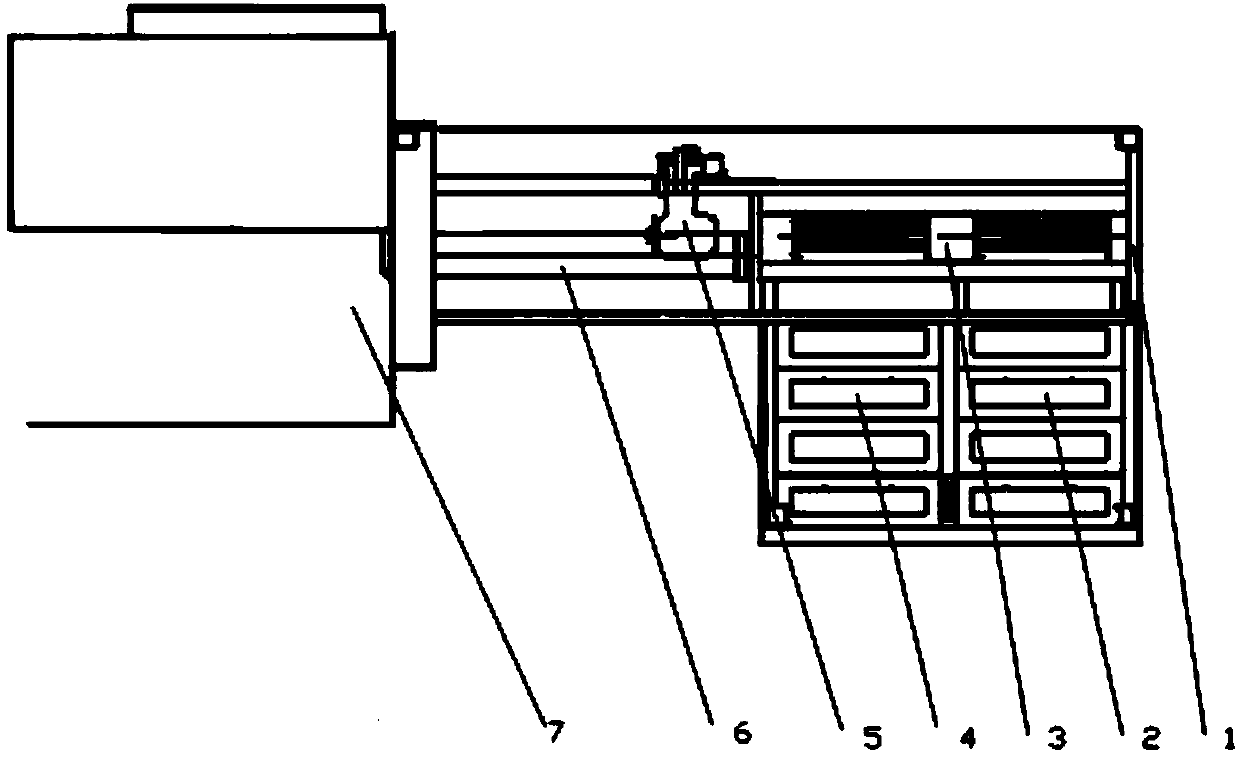

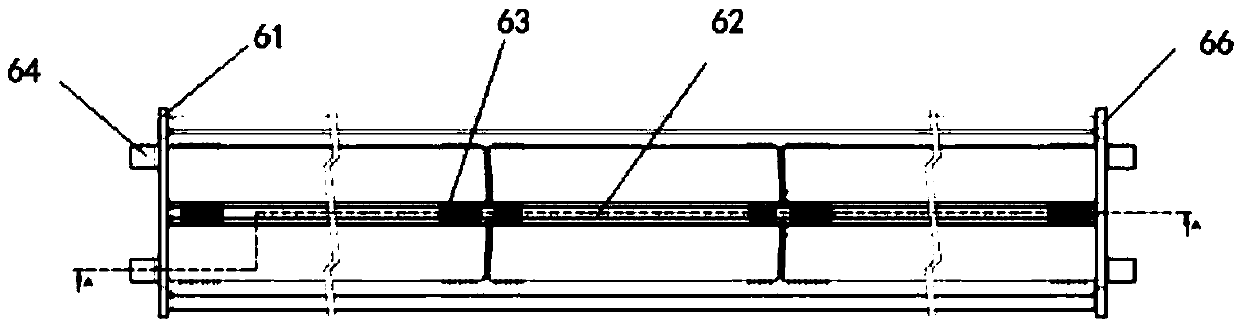

[0033] Such as figure 1 and figure 2 As shown, this example includes a furnace body 7, the furnace body 7 is connected to the equipment frame 1, a feeding mechanism and a blanking mechanism are arranged in turn on the equipment frame 1, and the feeding mechanism and the horizontal plane are provided with an inclination angle less than 10°. A manipulator 5 is set to grab and transfer silicon wafers. The feeding mechanism, unloading mechanism and manipulator are all controlled by the control system. Take out the fixed pitch and put it into the holding device 6. In this example, the holding device 6 adopts a quartz boat, which is transferred to the furnace body through the suction piece of the manipulator. The paddle and the screw drive mechanism are also arranged on the equipment frame 1, and the screw The transmission mechanism is arranged on the furnace mouth end close to the furnace body 7, and one end of the paddle is fixedly installed on the screw transmission mechanism, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com