Method for improving water chemical environment of soluble-boron-free coolant of nuclear power plant

A technology for nuclear power plants and coolants, applied in the field of nuclear safety, can solve problems such as increasing the use of chemical additives, difficulty in operation, investment costs, complex process and equipment configuration, and complex operation processes, etc., to achieve a simplified water chemical environment control strategy , Simplify the water chemistry control process and reduce the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

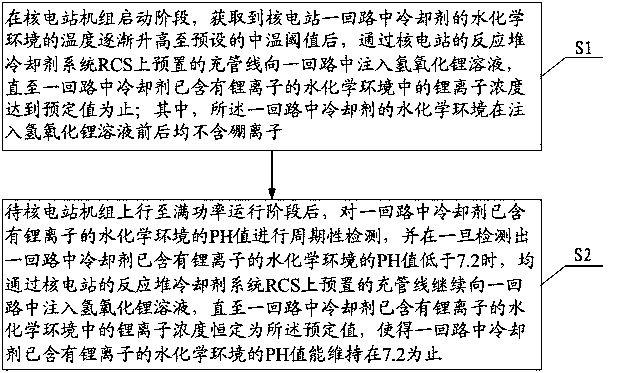

[0022] like figure 1 As shown, in an embodiment of the present invention, a method for improving the water chemical environment of a nuclear power plant based on no soluble boron coolant is provided, and the method includes the following steps:

[0023] Step S1. During the start-up phase of the nuclear power plant unit, after the temperature of the water chemical environment of the coolant in the primary circuit of the nuclear power plant is gradually increased to the preset medium temperature threshold, the pre-set charging pipeline on the reactor coolant system RCS of the nuclear power plant is sent to Lithium hydroxide solution is injected into the primary circuit until the concentration of lithium ions in the water chemical environment in which the coolant alr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com