Novel direct thermal low-voltage medium-power amplification tube

A technology of power amplification and electronic tubes, which is applied in the field of new direct-heating low-voltage medium power amplification electronic tubes, which can solve the problems of large filter volume, leakage, flashover, etc., and achieve the effect of small filter volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

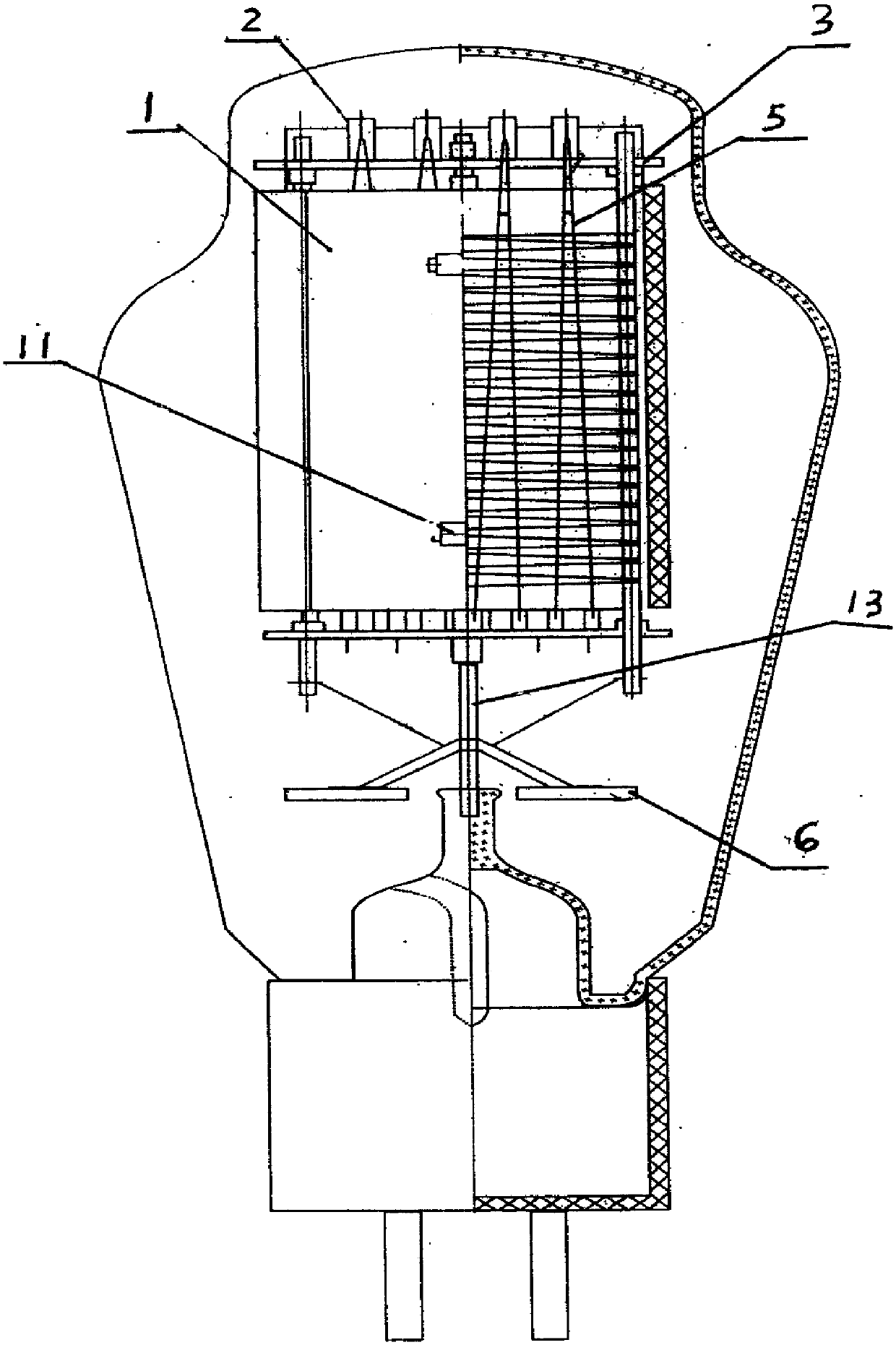

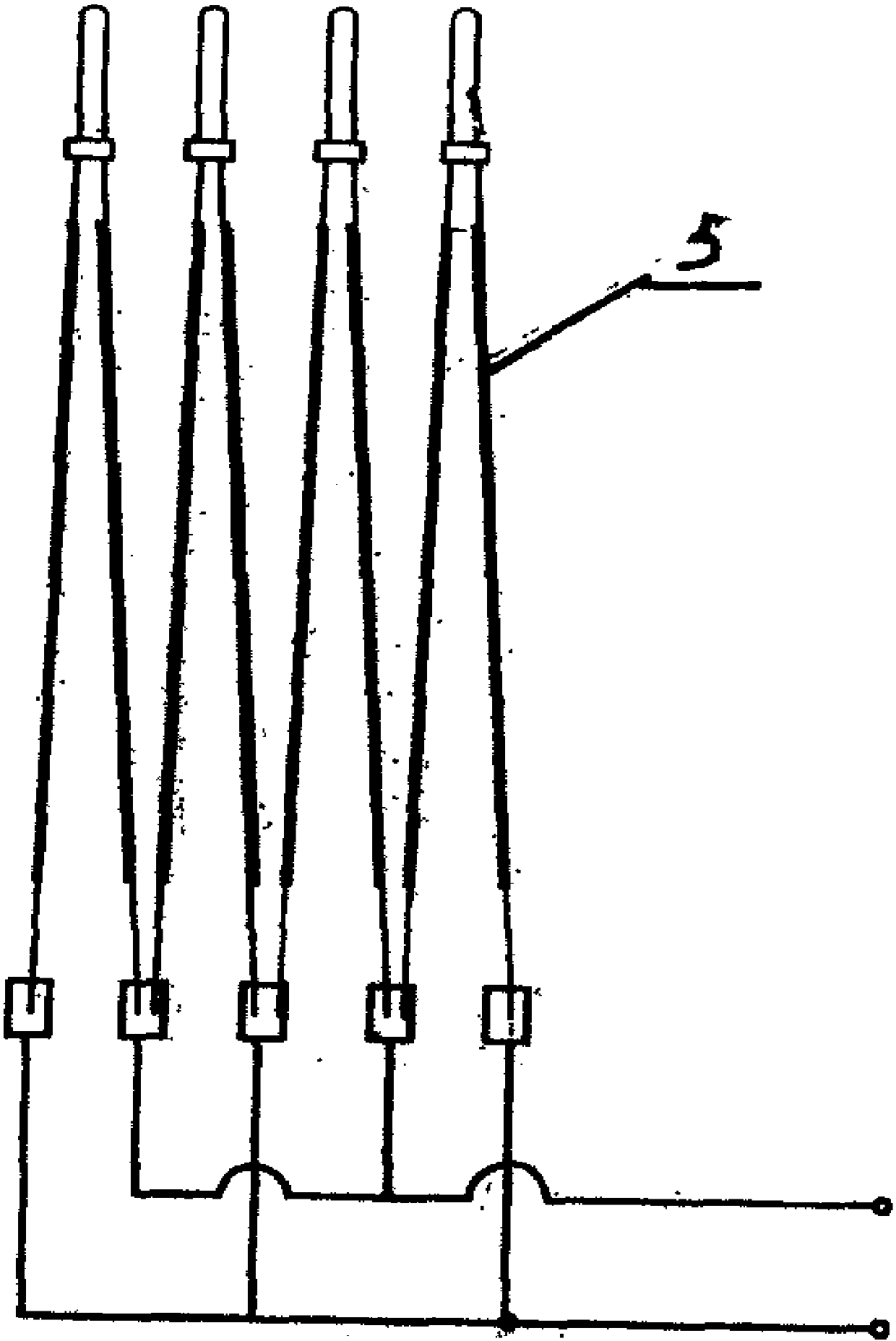

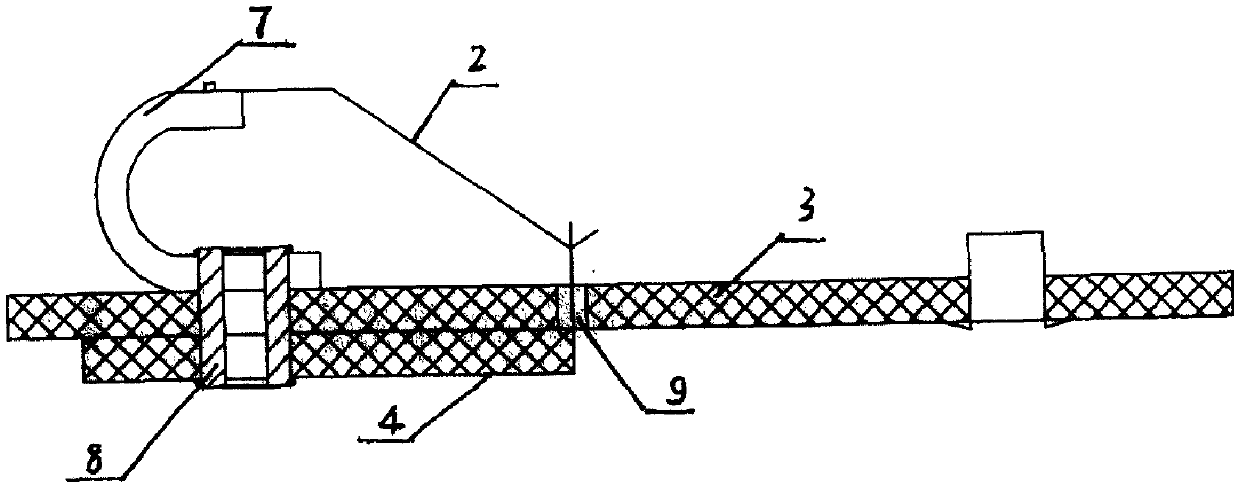

[0010] See above-mentioned accompanying drawing and can know the structure of the present invention. It is characterized in that: its electron tube core 1 is twice as long as the existing power amplification tube core, which is 110m, such as 300B power amplification tube core; its cathode is four groups of inverted V-shaped filament parallel structure cathode 5, composed of four A group of inverted V-shaped filaments 5 are connected in parallel, and the bow tie of the filament is hung on the hook 2; There is a hole, which is riveted on the left side of the upper combined mica sheet 3 and 4 of the electron tube by means of a hollow rivet 8; its cathode combined positioning mica sheet consists of a mica sheet 3 with a longitudinal through groove 9 in the center and a mica sheet mounted on its The positioning mica sheet 4 on the reverse side of the sheet is composed of the right end surface of the positioning mica sheet 4, the centerline of the groove 9 and the lifting point of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com