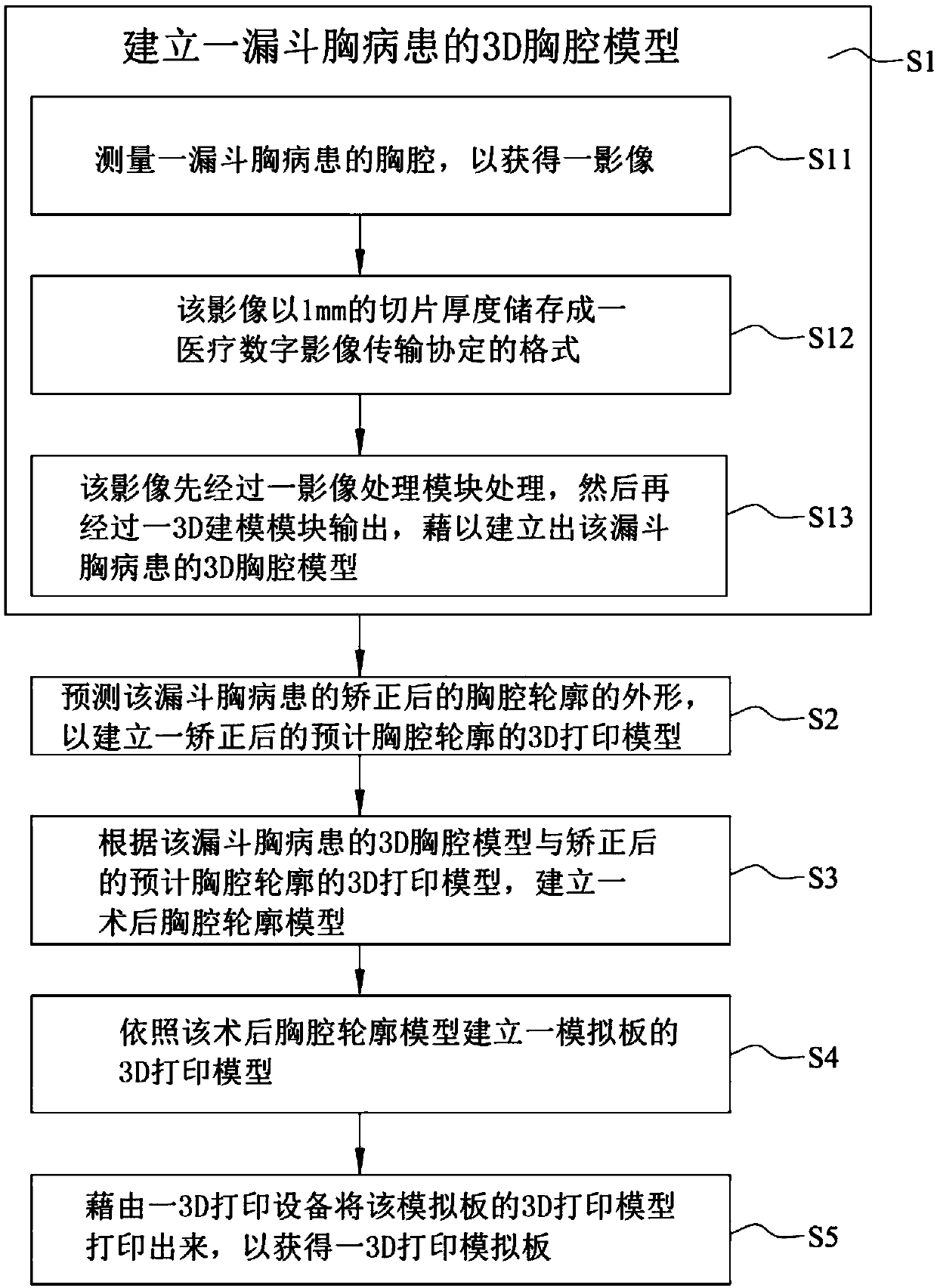

Manufacturing method applied to manufacture 3D printing simulation board of funnel chest correction board

A technology of 3D printing and manufacturing method, applied in the direction of outer plate, medical science, internal bone synthesis, etc., can solve the problems such as the inability of the pectus excavatum correction plate to fit closely with the ribs, misjudgment by doctors, errors in the shape of the chest cavity, etc., to reduce errors. The risk of judgment, shortening the operation time, and eliminating the effect of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

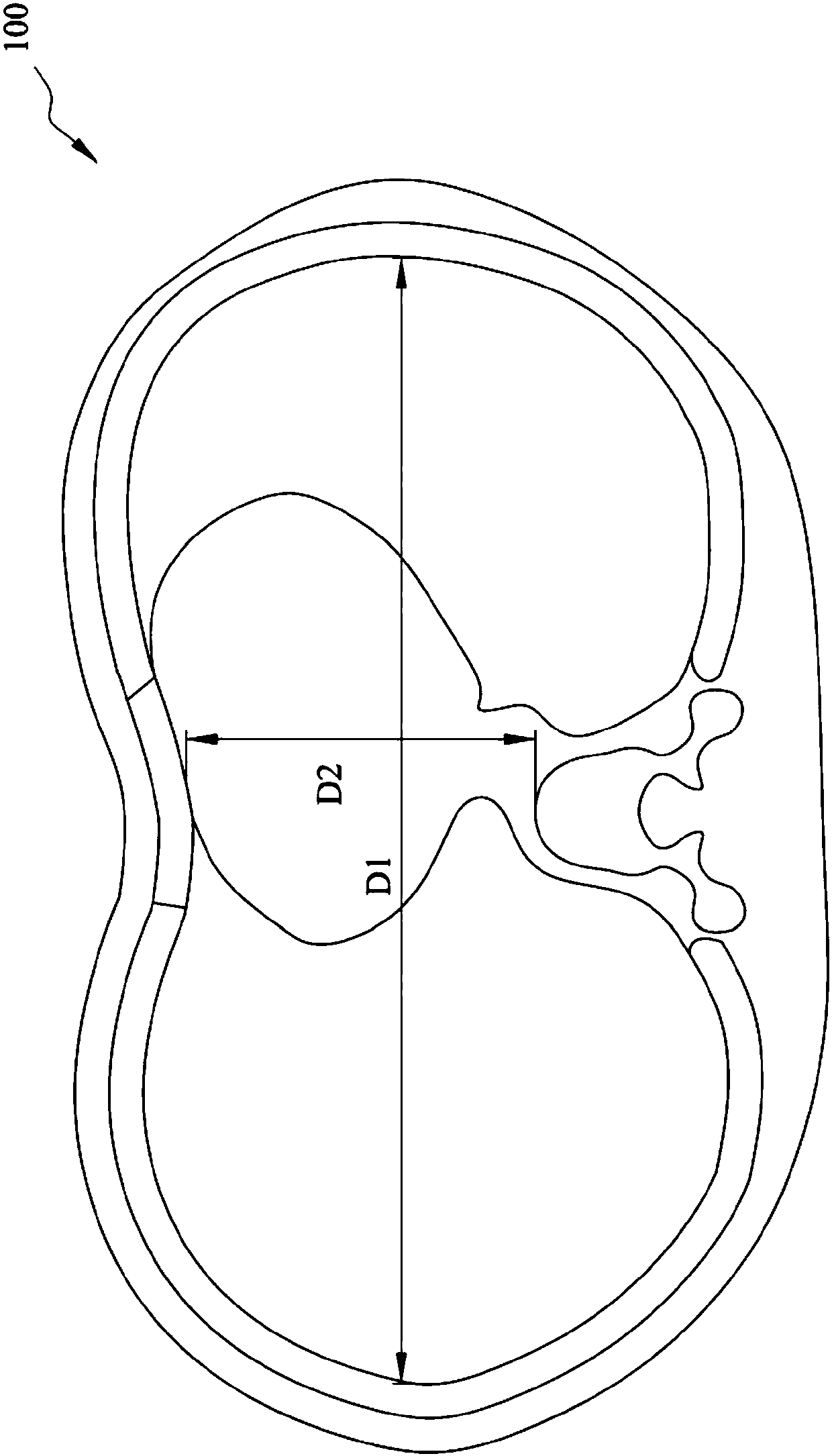

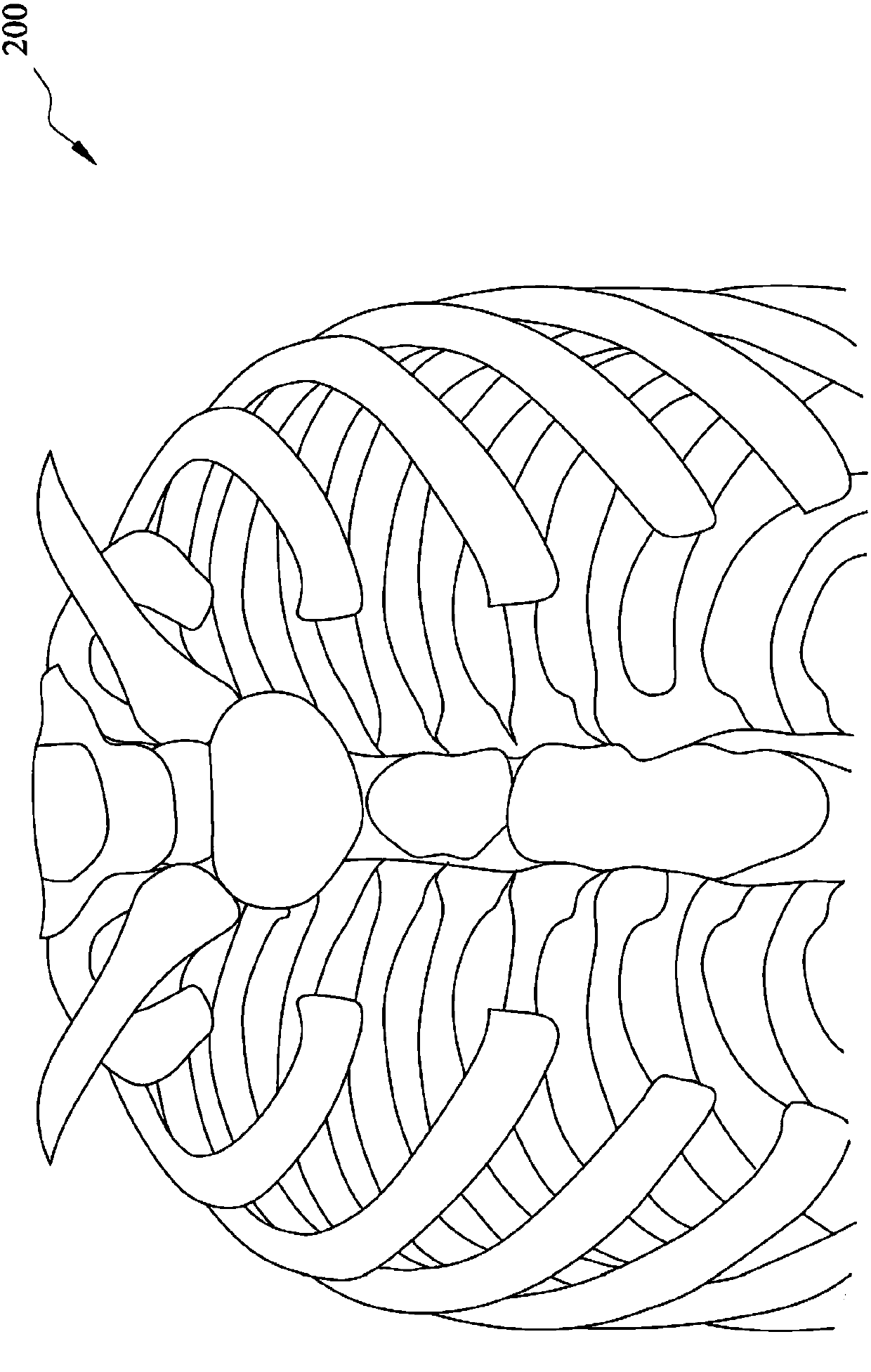

[0101]In this embodiment, the 3D printing simulation board 1 used to manufacture the pectus excavatum correction board is used to make a 10-digit funnel that is directly tailored to the shape of the chest cavity of an individual pectus excavatum patient and the curvature on both sides of the chest cavity by using the manufacturing method of the present invention. Taking a chest patient as an example, the preoperative data and postoperative correction data were analyzed and compared. The data analysis used SPSS 21.0 (developed by SPSS, Chicago, Illinois). Among them, the preoperative situation including the demographic data and baseline characteristics of patients with pectus pectus excavatum are sorted out in Table 1, and the postoperative correction situation is sorted out in Table 2.

[0102] Table I:

[0103] average age

19.80±4.73

Age range

12~26

gender

9 men and 1 woman

Average height (cm)

169.00±11.16

Height distribution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com