Method for determining chlorobenzene compounds in plastic product

A measurement method and technology for plastic products, applied in the direction of measurement device, material separation, analysis of materials, etc., can solve the problems of non-providance and implementation difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] The present invention has studied the influence of solvent on the measured value of recovery rate in sample, and result is as shown in table 1:

[0082] solvent type Acetone: dichloromethane (2:1) Acetone: dichloromethane (1:1) Acetone: dichloromethane (1:2) Acetone: dichloromethane (1:3) Recovery rate Recovery rate% Recovery rate% Recovery rate% Recovery rate% chlorobenzene 83.43 85.34 89.44 85.53 1,3-Dichlorobenzene 86.73 89.47 93.53 90.51 1,4-Dichlorobenzene 88.29 91.10 94.90 90.12 1,2-Dichlorobenzene 88.23 91.02 94.99 89.2 1,3,5-Trichlorobenzene 88.78 91.90 95.12 93.58 1,2,4-Trichlorobenzene 87.94 91.34 94.21 93.36 1,2,3-Trichlorobenzene 87.62 91.11 93.84 83.57 1,2,3,5-tetrachlorobenzene 88.70 92.36 94.33 96.02 1,2,4,5-tetrachlorobenzene 88.66 92.55 94.36 93.31 1,2,3,4-Tetrachlorobenzene 88.09 92.09 94.12 91.46 Pentachlorobenzene 87.26 91.85 ...

Embodiment 2

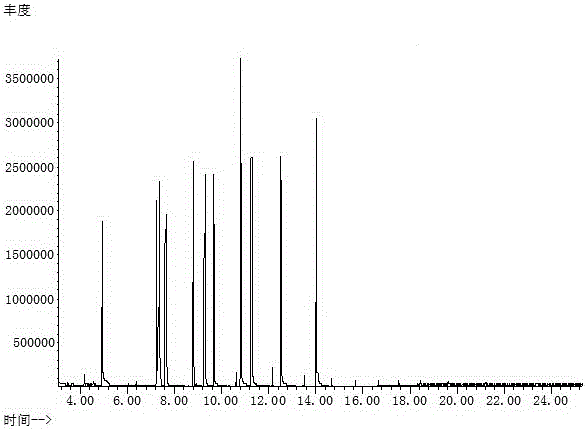

[0085] For the extraction of the substances to be tested in plastics, two methods can be selected: Soxhlet extraction and microwave extraction. Compared with microwave extraction, Soxhlet extraction takes too long and consumes more solvents, which is not conducive to experimental needs and is not conducive to Environmental protection, the present invention selects the microwave extraction method, takes the mixed standard solution of known concentration and carries out the standard addition recovery experiment, the result is as follows:

[0086]

[0087] Experimental analysis shows that microwave extraction was used to extract 12 kinds of mixed chlorobenzene compounds, and the recovery rate was more than 85%, which were all within a reasonable range. The experiment proved that microwave extraction was time-consuming, less solvent was used, and the recovery rate was high.

Embodiment 3

[0089] In this example, 0.1g of colored ABS (dark red) powder was weighed, and 5ml of acetone:dichloromethane (1+1) was added for extraction. The following SPE column was activated with 5ml of acetone:dichloromethane (1+1), loaded and observed Purification effect:

[0090] SPE column Specification Purification effect C18 1000mg / 6ml The purification solution is red Florisil 1000mg / 6ml The purification solution is red PA 1000mg / 6ml Purification liquid is light pink

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com