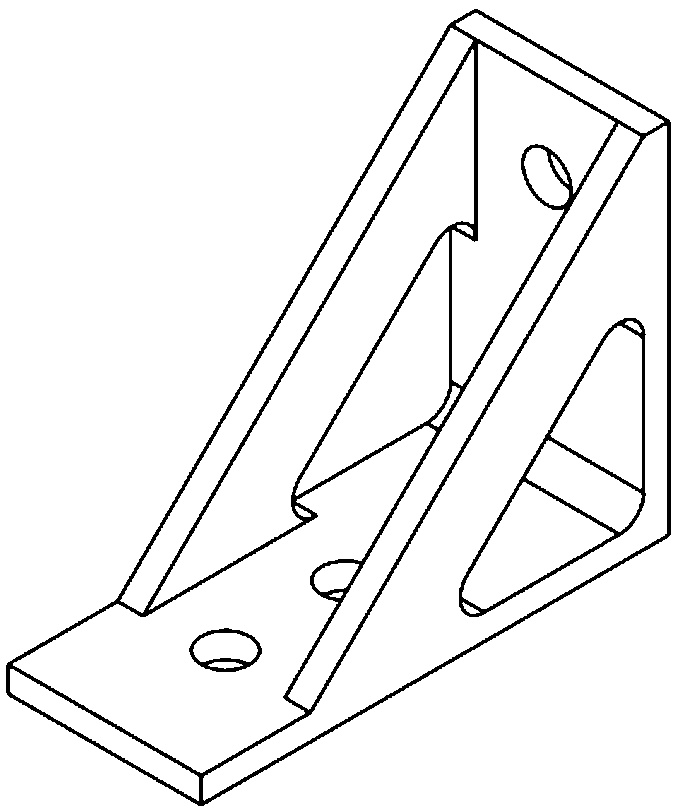

Machining method of fiber reinforced composite material connecting piece

A composite material and fiber reinforced technology, applied in the field of composite material application manufacturing, can solve the problems of inability to process angle steel, weight reduction, etc., and achieve the effect of large allowable stress range, weight reduction, and strength satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] A processing method of a fiber-reinforced composite connector of the present invention, the specific steps are as follows:

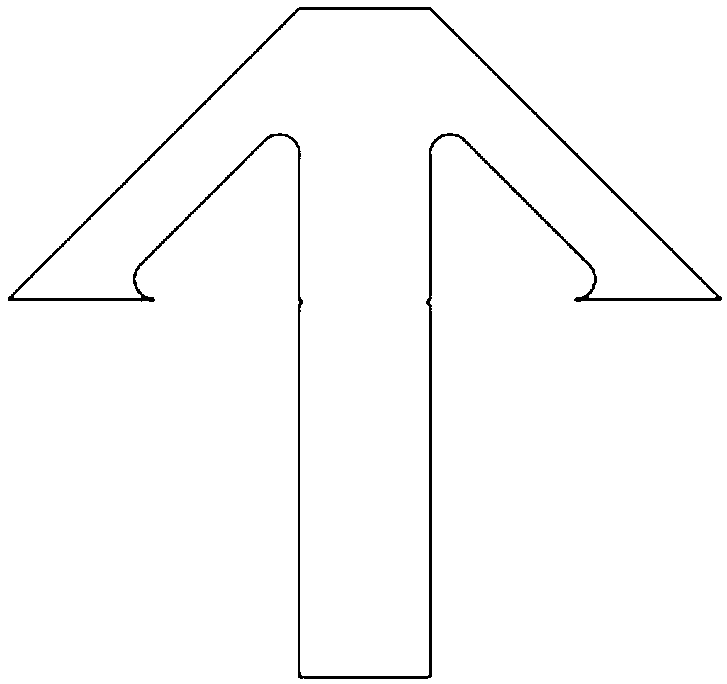

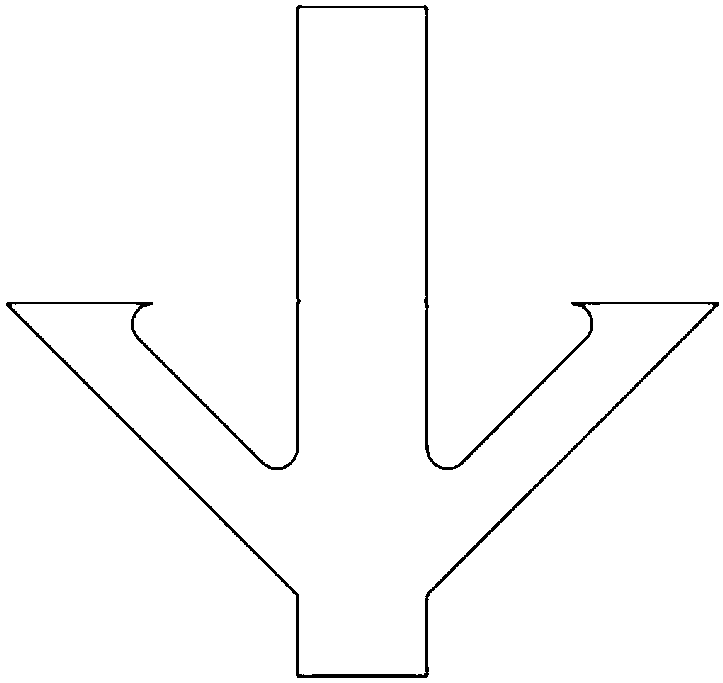

[0026] 1) Cut the sheet-like fiber cloth into two groups of umbrella-shaped adhesive sheets, each umbrella-shaped adhesive sheet is composed of a rectangular support part in the middle, and a connecting arm extending symmetrically and obliquely from one end to the other end of the rectangular support part; each umbrella-shaped adhesive sheet The length and width of the rectangular support portion of the umbrella-shaped adhesive sheet match the total length and width of the two connecting plates of the connecting piece to be processed, and the angle between the connecting arm of each umbrella-shaped adhesive sheet and the rectangular support portion is the same as that of the connecting piece to be processed. The included angles of the two connecting plates are complementary; the middle part of the rectangular support part of each umbrella-shaped ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com