Wrapping paper rewinding and cutting and inkjet packaging production line and operation method

A packaging production line and operation method technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of inability to guarantee process consistency, the impact of packaging paper quality, and unstable packaging quality, so as to reduce the labor intensity of workers and improve the quality of packaging. The effect of high degree of automation control and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

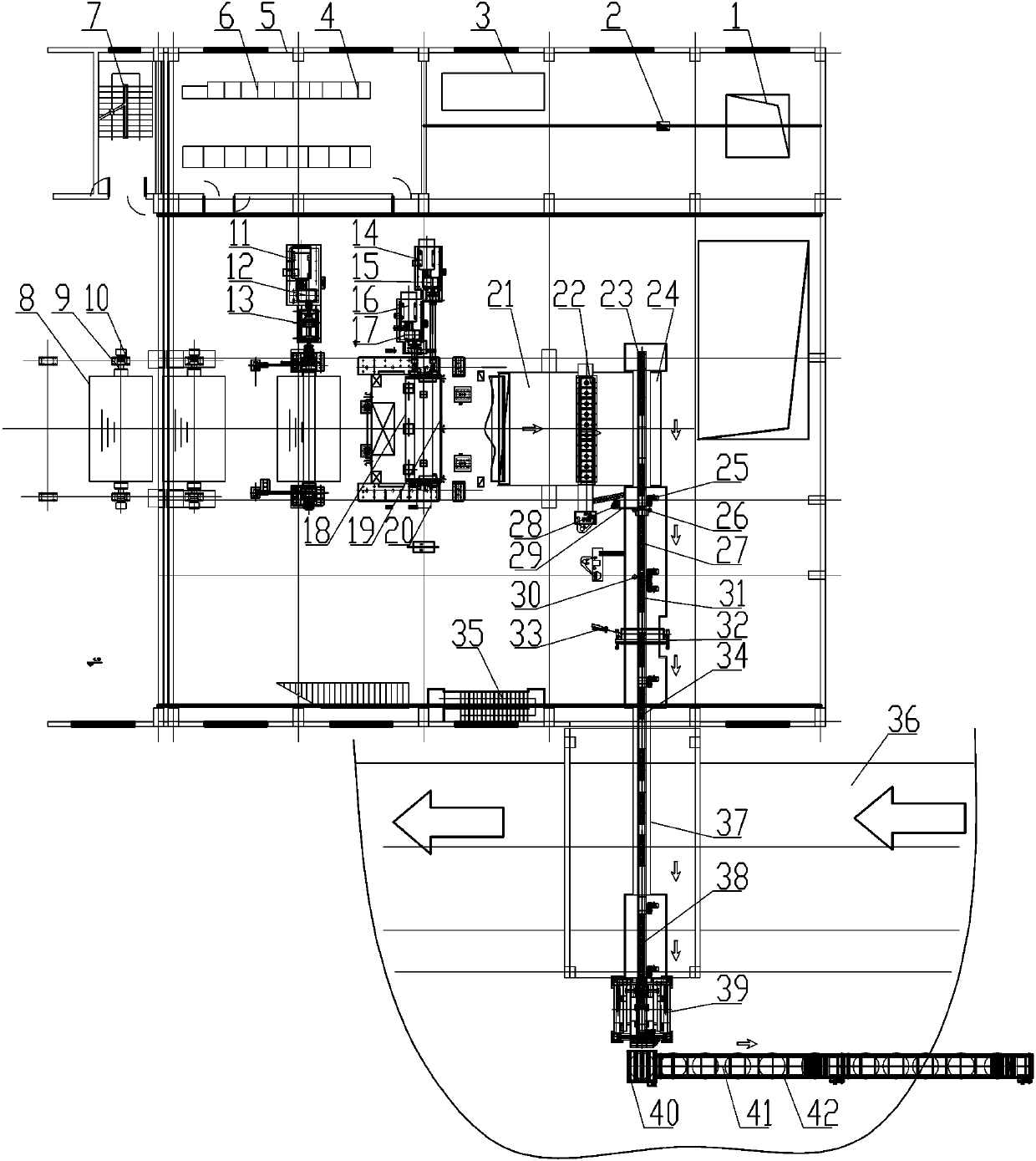

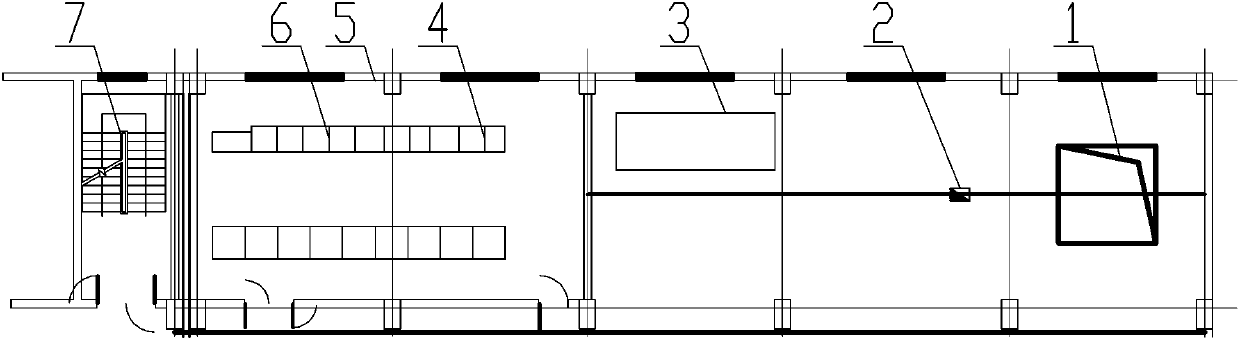

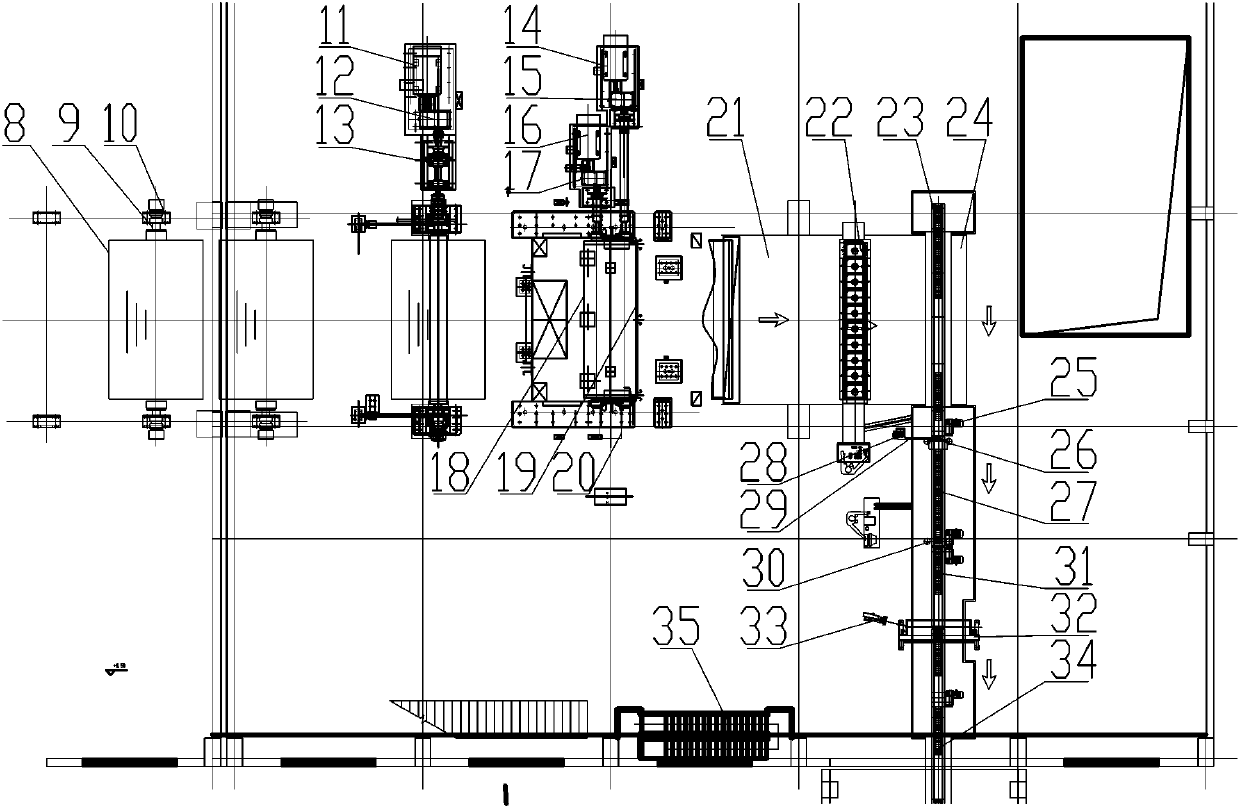

[0049] like Figure 1-6 As shown, the packaging paper rewinding blanking and inkjet packaging production line includes a paper roll storage area 3 for raw paper roll storage, and a rewinding system for paper roll rewinding is installed outside the paper roll storage area 3; The rewinding system includes a plurality of paper racks 10 for paper roll support, and an unwinding device for unwinding raw paper rolls is arranged behind the paper racks 10; the paper output end of the unwinding device is provided with a rewinding Winding machine, the discharge section of the rewinder is docked with the turning and unloading mechanism 21 for unloading small paper rolls after rewinding, the end of the turning and unloading mechanism 21 is provided with a stop distributor 22, the After the stop distributor 22, a paper roll stopper 24 for blocking is provided, and the inside of the paper roll stopper 24 is provided with a first V-chain conveyor 23 for small paper roll delivery. On the conv...

Embodiment 2

[0059] The operation method of any one of the packaging paper rewinding and blanking and inkjet packaging production line includes the following steps:

[0060] Step1: Hoist the manufactured base paper roll 8 to the paper roll storage area 3 through the paper core hoisting hole 1 through the monorail electric hoist 2 for orderly stacking;

[0061] Step2: pass the center of the base paper roll 8 through the support roller 9, and hoist it as a whole on the paper rack 10 by driving, and support it through the paper rack 10;

[0062] Step3: Start the unwinding device to unwind the base paper roll 8, and send the base paper to the rewinder, and rewind it through the rewinder;

[0063] Step4: After the rewinding is completed, start the turning and unloading mechanism 21, and place a plurality of small paper rolls 42 at the position where the stop distributor 22 is located;

[0064] Step5: place a plurality of small paper rolls 42 on the first V-chain conveyor 23 in sequence accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com