A rh refining method to control the wettability of inclusions in low carbon aluminum killed steel

A low-carbon aluminum-killed steel and inclusion technology, which is applied in the steelmaking field of the metallurgical industry, can solve problems such as mold flow field instability, billet quality problems, submerged nozzle nodules, etc., and achieve the improvement of nozzle nodules, The effect of saving pouring costs and alleviating the problem of nozzle nodules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

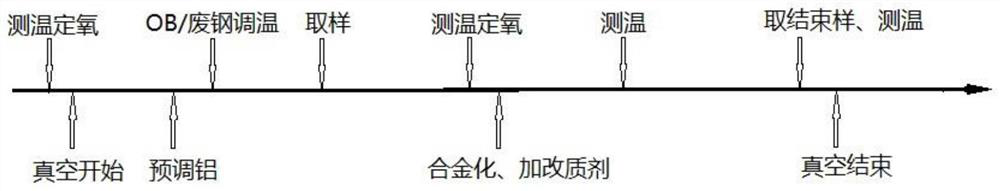

[0034] This embodiment provides a RH refining method for controlling the wettability of inclusions in low-carbon aluminum-killed steel, the steps of which include:

[0035] 1. The molten steel is smelted in an electric furnace or a converter, and the tapping process adopts quiet tapping. When 1 / 5 of the steel is tapped, add a deoxidizer with an aluminum content of 40% and an iron content of 60%. The deoxidizer is a deoxidizer based on an inorganic matrix. The ratio of 70kg of deoxidizer is added.

[0036] 2. When 2 / 5 of the steel is tapped, small lime with a calcium oxide content of 85% is added, the particle size of the small lime is controlled at 10-30mm, and the activity is ≥350ml / L. Adjust the amount of lime added according to the oxygen content in the steel when tapping. In this embodiment, the oxygen content of the molten steel is less than or equal to 650ppm, and the amount of lime added is 2.5kg / ton of steel.

[0037] 3. When the RH enters the station, turn on the b...

Embodiment 2

[0058] This embodiment provides a RH refining method for controlling the wettability of inclusions in low-carbon aluminum-killed steel, the steps of which include:

[0059] 1. The molten steel is smelted in an electric furnace or a converter, and the tapping process adopts quiet tapping. When 2 / 5 of the steel is tapped, add a deoxidizer with an aluminum content of 50% and an iron content of 50%. The deoxidizer is a deoxidizer based on an inorganic matrix. The ratio of 90kg of deoxidizer is added.

[0060] 2. When 2 / 5 of the steel is tapped, small lime with a calcium oxide content of 90% is added, the particle size of the small lime is controlled at 10-30mm, and the activity is ≥350ml / L. Adjust the amount of lime added according to the oxygen content in the steel when tapping. In this embodiment, the oxygen content of molten steel is 800ppm, which is greater than 650ppm, and the amount of lime is added according to the ratio of 3+(800-650) / 100=4.5kg / ton of steel.

[0061] 3....

Embodiment 3

[0068] This embodiment provides a RH refining method for controlling the wettability of inclusions in low-carbon aluminum-killed steel, the steps of which include:

[0069] 1. The molten steel is smelted in an electric furnace or a converter, and the tapping process adopts quiet tapping. When 2 / 5 of the steel is tapped, add a deoxidizer with an aluminum content of 75% and an iron content of 25%. The deoxidizer is a deoxidizer based on an inorganic matrix. The ratio of 55kg of deoxidizer is added.

[0070] 2. When 2 / 5 of the steel is tapped, small lime with a calcium oxide content of 80% is added, the particle size of the small lime is controlled at 10-30mm, and the activity is ≥350ml / L. Adjust the amount of lime added according to the oxygen content in the steel when tapping. In this embodiment, the oxygen content of molten steel is 950ppm, which is greater than 650ppm, and the amount of lime is added according to the ratio of 2+(950-650) / 100=5kg / ton of steel.

[0071] 3. W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com