Assembled laminated floor slab and its construction method based on tool-type hanging formwork

A superimposed floor, prefabricated technology, applied in the processing of floor, building materials, construction, etc., can solve the problems of blindness in the implementation and inspection of construction plans, affecting the normal use of superimposed floors, lack of theoretical guidance, etc. Construction quality and efficiency, eliminating the need for demolding procedures, and improving the effect of economic and technical benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

[0044] Before construction, according to the construction drawings, check the type of laminated floor components, determine the installation location, number them according to the hoisting sequence, pop up the level and elevation control lines of the laminated floor on site, and carry out inspection and acceptance.

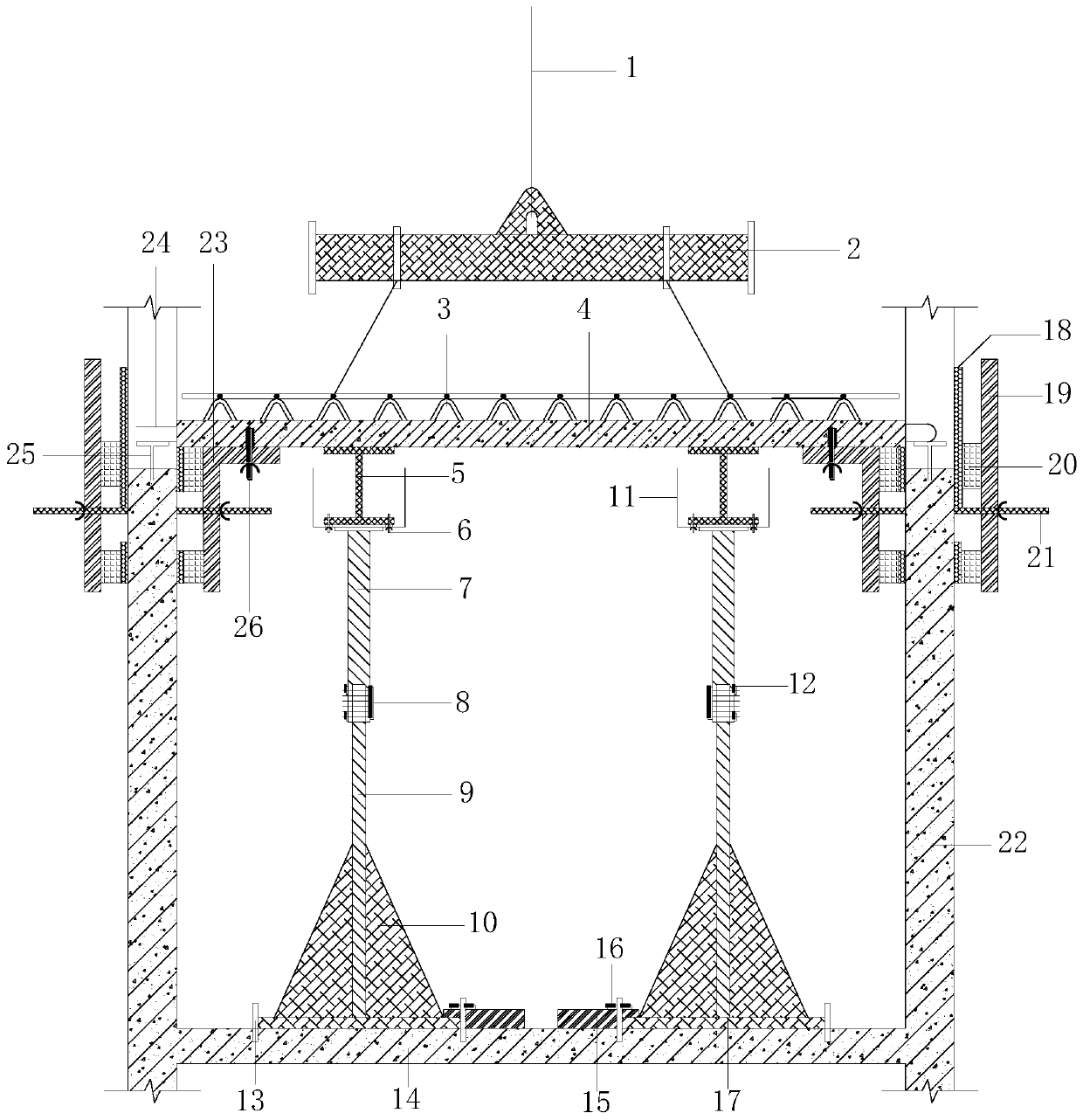

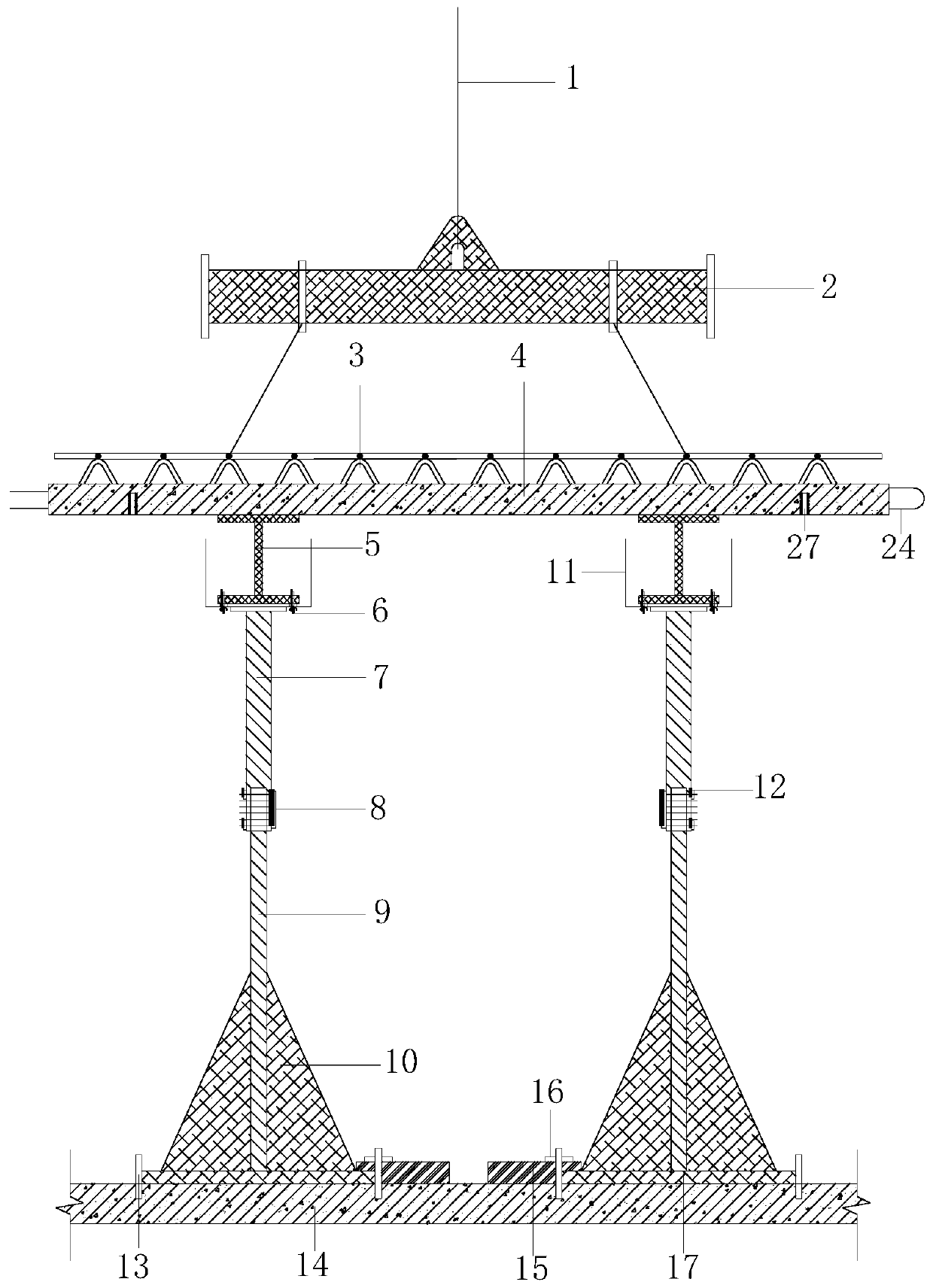

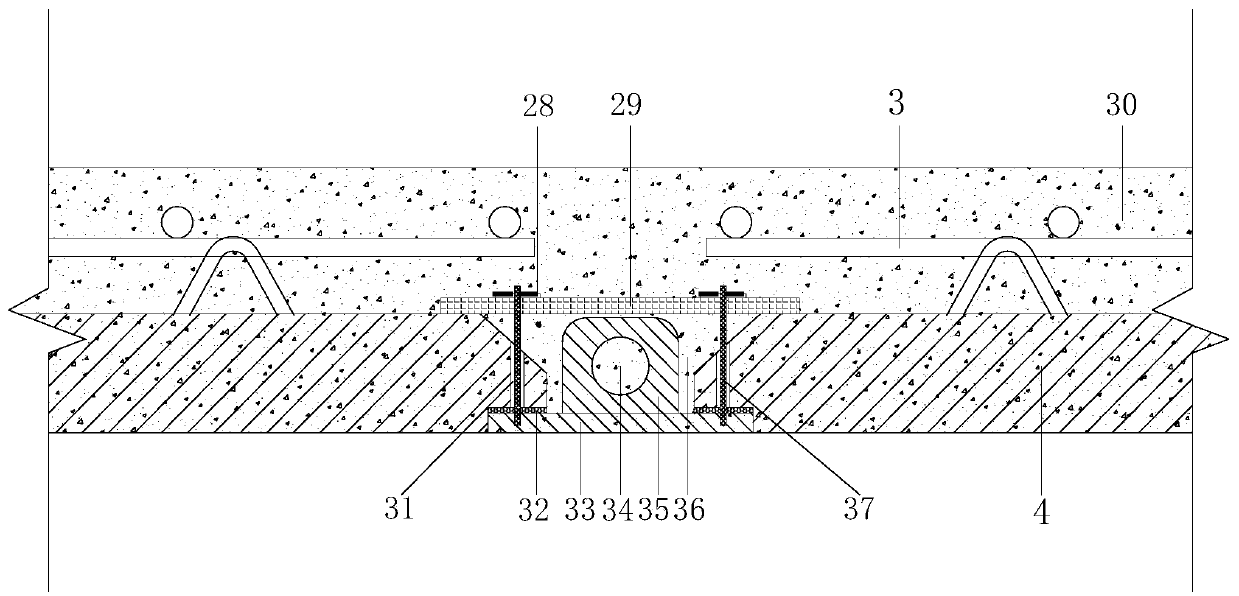

[0045] The lower vertical pole of the adjustable and shaped support has its own reinforced rib plate, which is connected with the frame plate base 17,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com