Photoelectric circuit packaging device based on ceramic carrier board

A circuit packaging and carrier board technology, applied in the field of sensors, can solve the problems of reduced reliability, space redundancy, low thermal conductivity, etc., and achieve the effects of reduced size and height, high-speed circuit design, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

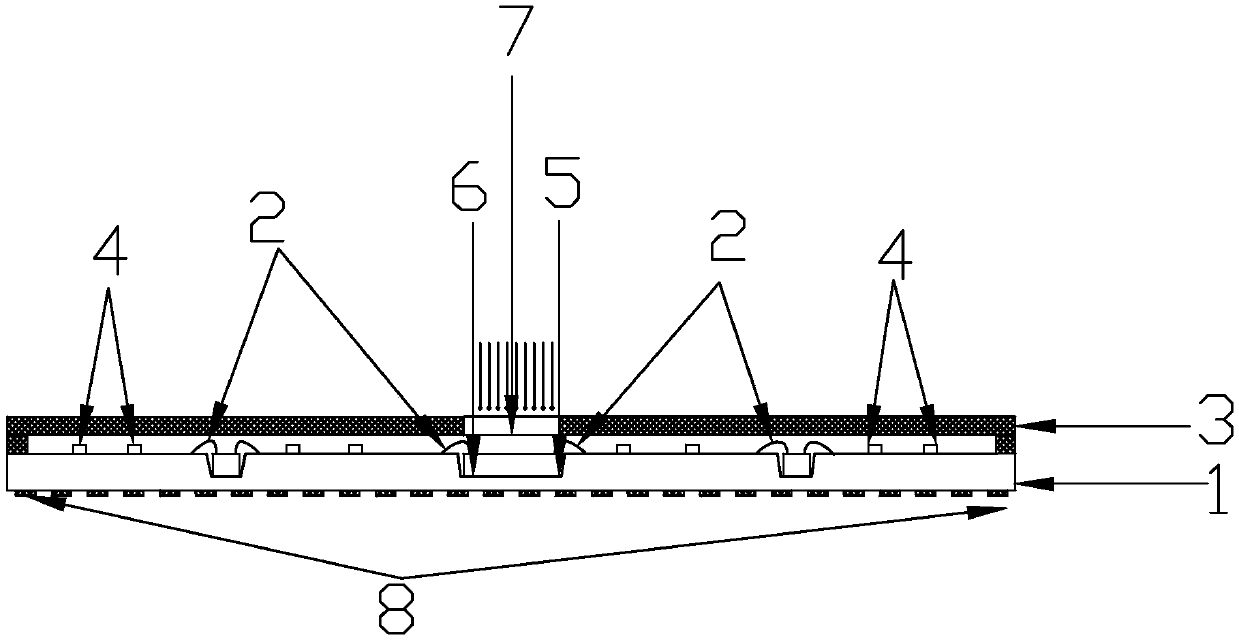

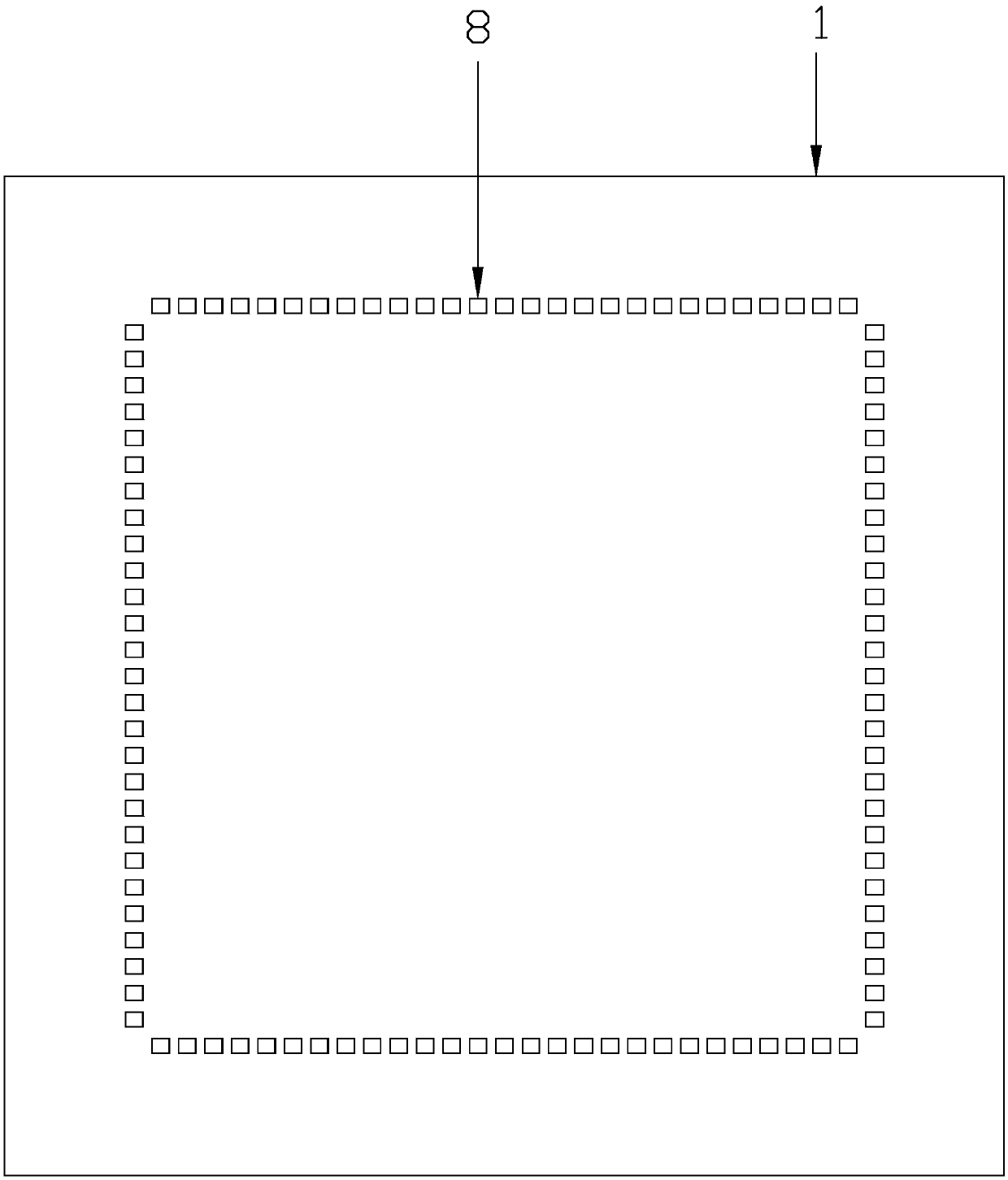

[0017] like figure 1 As shown, it shows a photoelectric circuit packaging device based on a ceramic carrier, which includes a ceramic carrier 1, gold wires 2, and a ceramic cover. The ceramic carrier 1 and the ceramic cover 3 are sealed with a metal Sealed connection (such as brazing method, which is to add some active elements such as Ti and Zr to the solder, and its content is usually below 5%, such as (Ag-28, Cu-12, In-1, Ti) to combine metal and Ceramics are directly brazed), the inner surface of the ceramic carrier plate 1 is provided with circuit lines, the first cavity 5 and the second cavity 4, the first cavity 5 is placed with a photoelectric chip 6, preferably, the first cavity 5 and the depth of the second recess 4 are both 0.5 mm. The photoelectric chip 6 is electrically connected to the peri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com