Rotary compressor

a compressor and rotary technology, applied in the field of compressors, can solve the problems of increasing the size of the eccentric and its corresponding counterweight, and the design and assembly of such a compressor becoming more difficult, so as to maintain the balance, and reduce the load of the bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

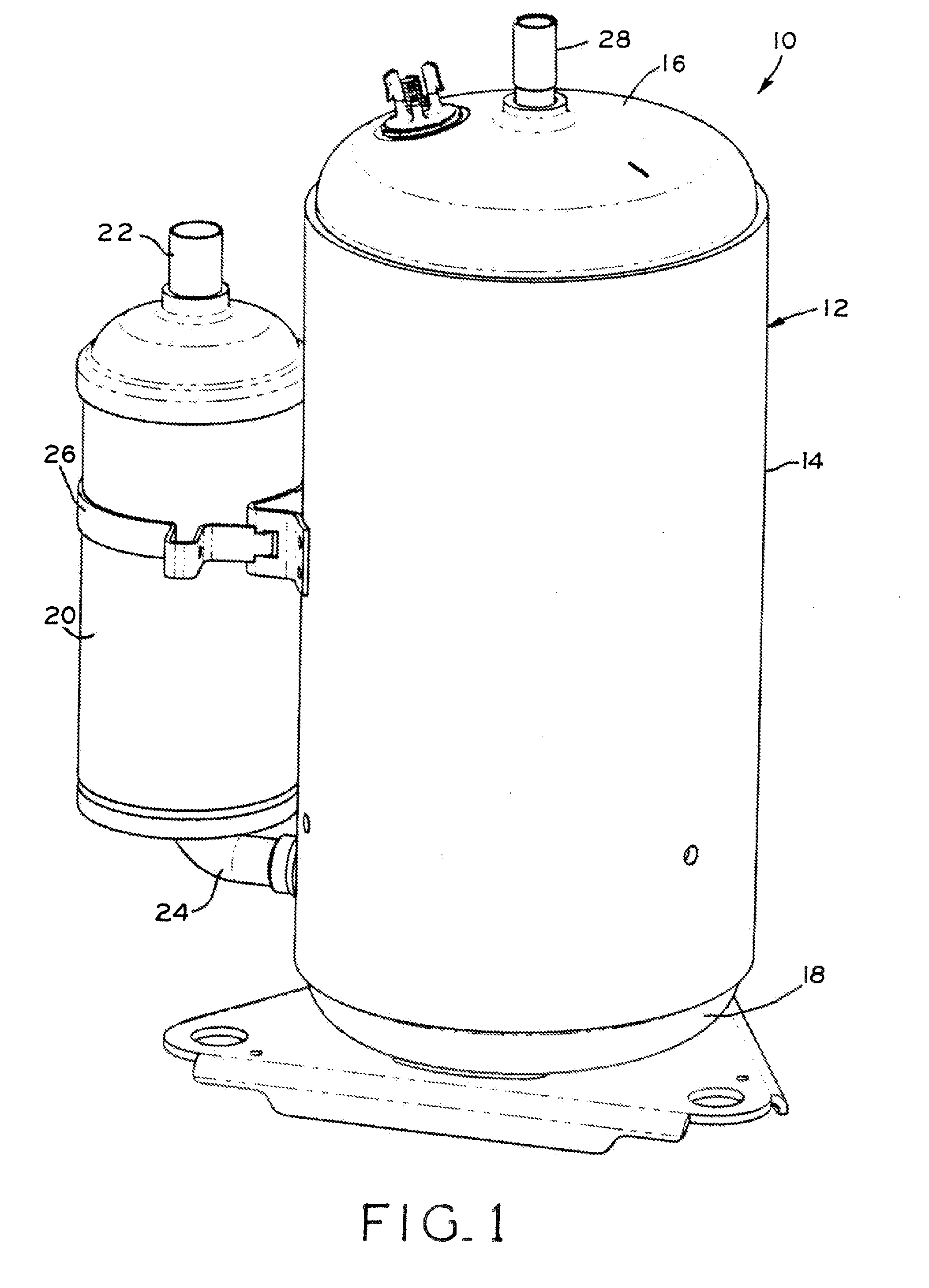

[0024]FIG. 1 illustrates the rotary compressor 10 forming one embodiment of the present invention. Compressor 10 includes an outer hermetic housing 12 including center portion 14 to which upper and lower caps 16 and 18 are connected, such as by welding. A conventional suction accumulator 20 having inlet 22 and outlet suction line 24 is connected to the center portion 14 of compressor 10 by means of mounting strap 26. Compressed refrigerant is discharged from high pressure housing 12 through discharge line 28. Compressor 10 may be a component of a heating and / or cooling circuit and functions to compress the working fluid, such as a refrigerant, which may be a hydrofluorocarbon, chlorofluorocarbon, hydrochlorofluorocarbon, or carbon dioxide refrigerant, for example.

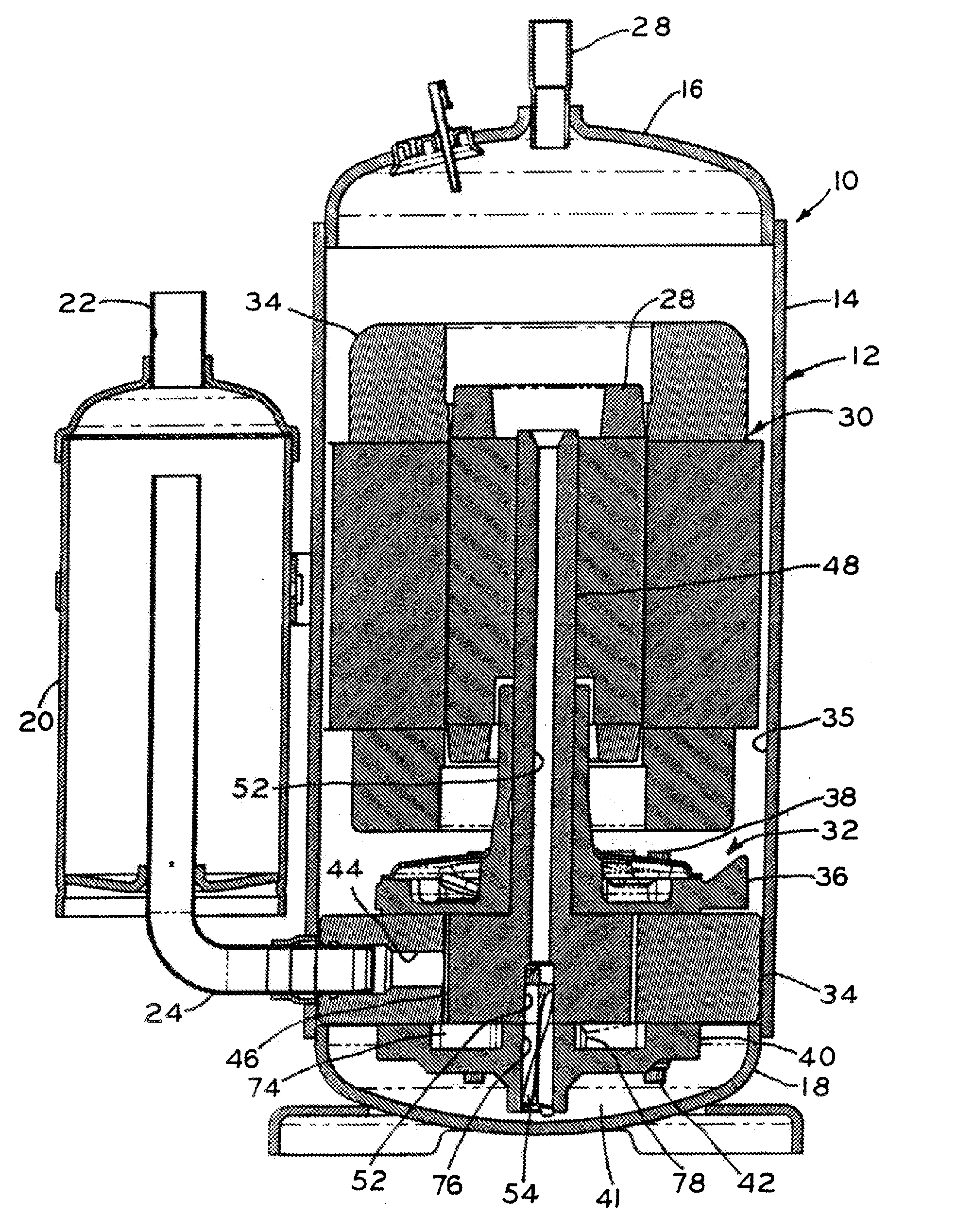

[0025]Turning now to FIGS. 3-5, motor 30 and compression mechanism 32 are mounted within hermetic housing 12. Oil sump 41 (FIG. 3) is formed in the lower portion of hermetic housing 12. The motor includes stator 34 and roto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com