Preparation method of manganese oxide/zinc oxide negative electrode material

A manganese monoxide, negative electrode material technology, applied in negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of uneven size, low yield, large skeleton, etc., to improve electrochemical stability and particle dispersion. Good, improve the effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] Example 1:

[0024] The preparation method of a kind of manganese monoxide / zinc oxide negative electrode material of this embodiment, its specific steps are as follows:

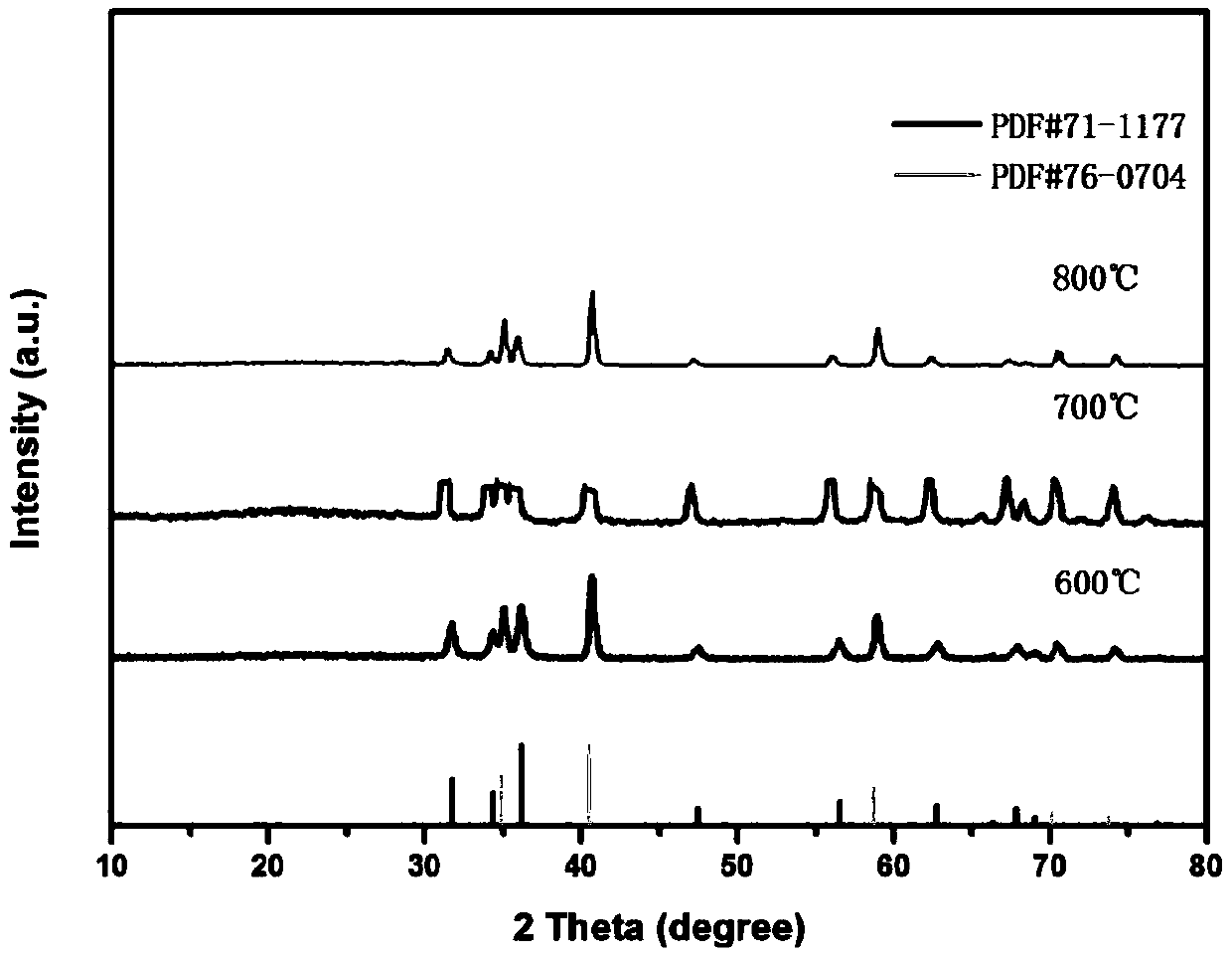

[0025] 1. Hydrothermal Synthesis of α-MnO 2

[0026] Weigh 0.316g of potassium permanganate and dissolve it in 30mL of deionized water, mix and stir in the container for 10 minutes, the stirring speed is 200r / min; add 3.6mL of 3mol / L hydrochloric acid, continue to stir for 5 minutes; transfer to the autoclave, Perform hydrothermal reaction at 160°C for 6 hours, centrifuge the suspended reaction solution at a speed of 10,000r / min for 5 minutes, then wash the precipitate with deionized water and absolute ethanol three times, deionized water and anhydrous The amount of ethanol is 80ml, and then dried at 60°C for 6 hours to obtain brown α-MnO 2 powder.

[0027] 2. Weigh 0.6g of dimethylimidazole and 0.3g of polyvinylpyrrolidone and dissolve them in 10mL of methanol to make solution A, the stirring sp...

Example Embodiment

[0033] Example 2:

[0034] The preparation method of a kind of manganese monoxide / zinc oxide negative electrode material of this embodiment, its specific steps are as follows:

[0035] 1. Hydrothermal Synthesis of α-MnO 2 Same as in Example 1;

[0036] 2. Weigh 0.6g of dimethylimidazole and 0.6g of polyvinylpyrrolidone and dissolve them in 10mL of methanol to make solution A, the stirring speed is 300r / min, and the stirring time is 3 minutes; weigh 0.3g of zinc nitrate and 0.04g of α-MnO 2 Dissolve in 20mL of methanol to make solution B, the stirring speed is 300r / min, and the stirring time is 3 minutes;

[0037] 3. Mix 10mL of solution A and 20mL of solution B to form solution C, and stir at room temperature for 24 hours at a stirring speed of 280r / min;

[0038] 4. Centrifuge the solution C at a speed of 11000r / min for 5 minutes, then wash the precipitate with methanol solution three times, and the amount of methanol used is 200ml;

[0039] 5. Dry the precipitate in ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap