Glue-free fiber bar production line

A fiber rod and production line technology, which is applied to the processing and production of glue-free fiber rods. field, which can solve the problems of physical injury, explosion and loss of production personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

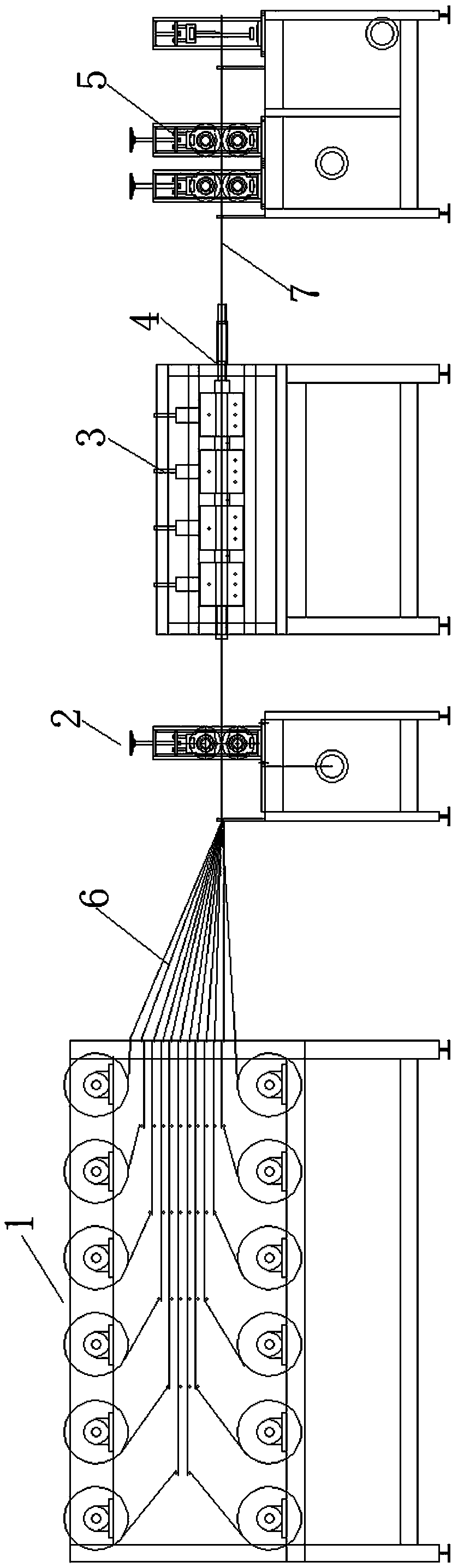

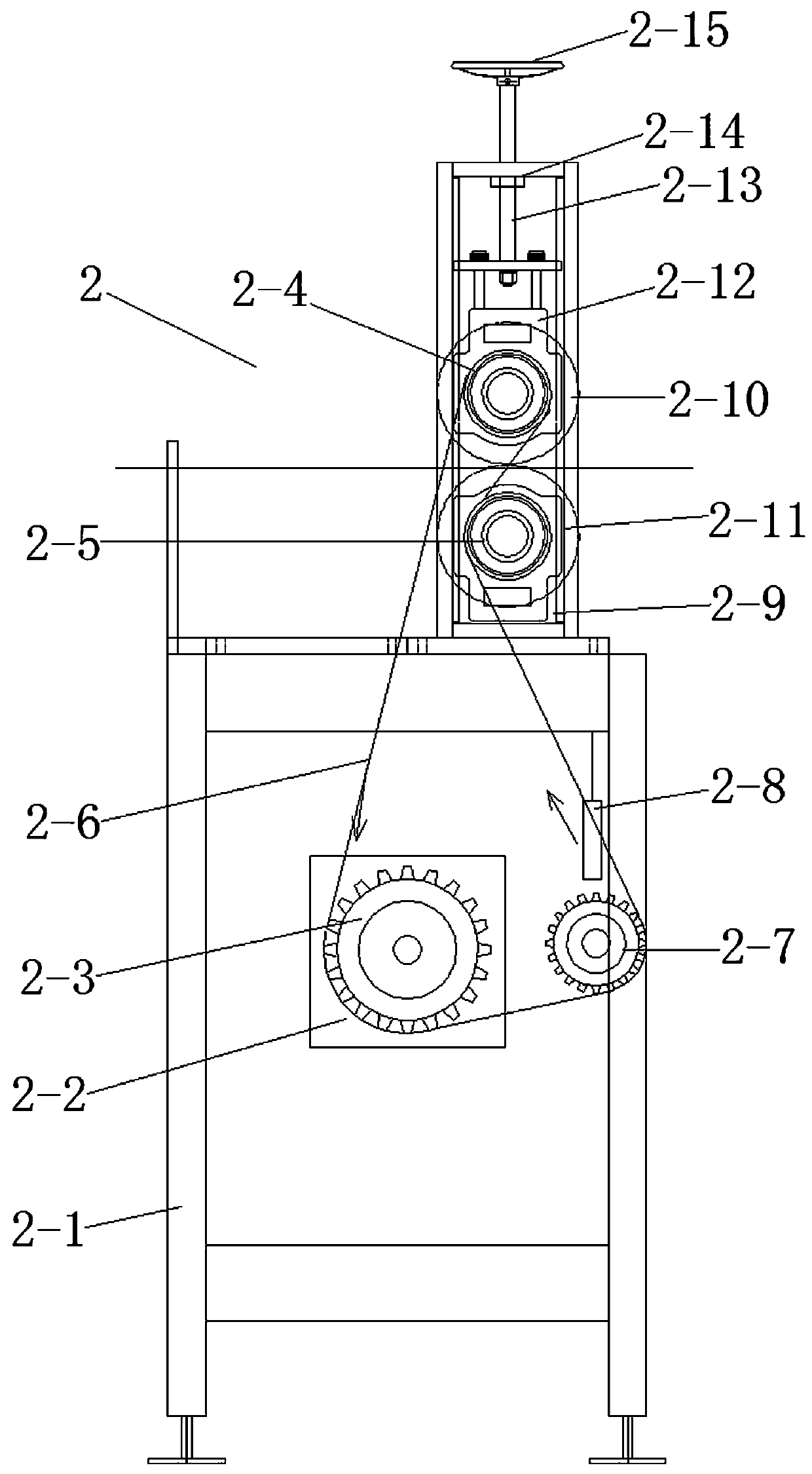

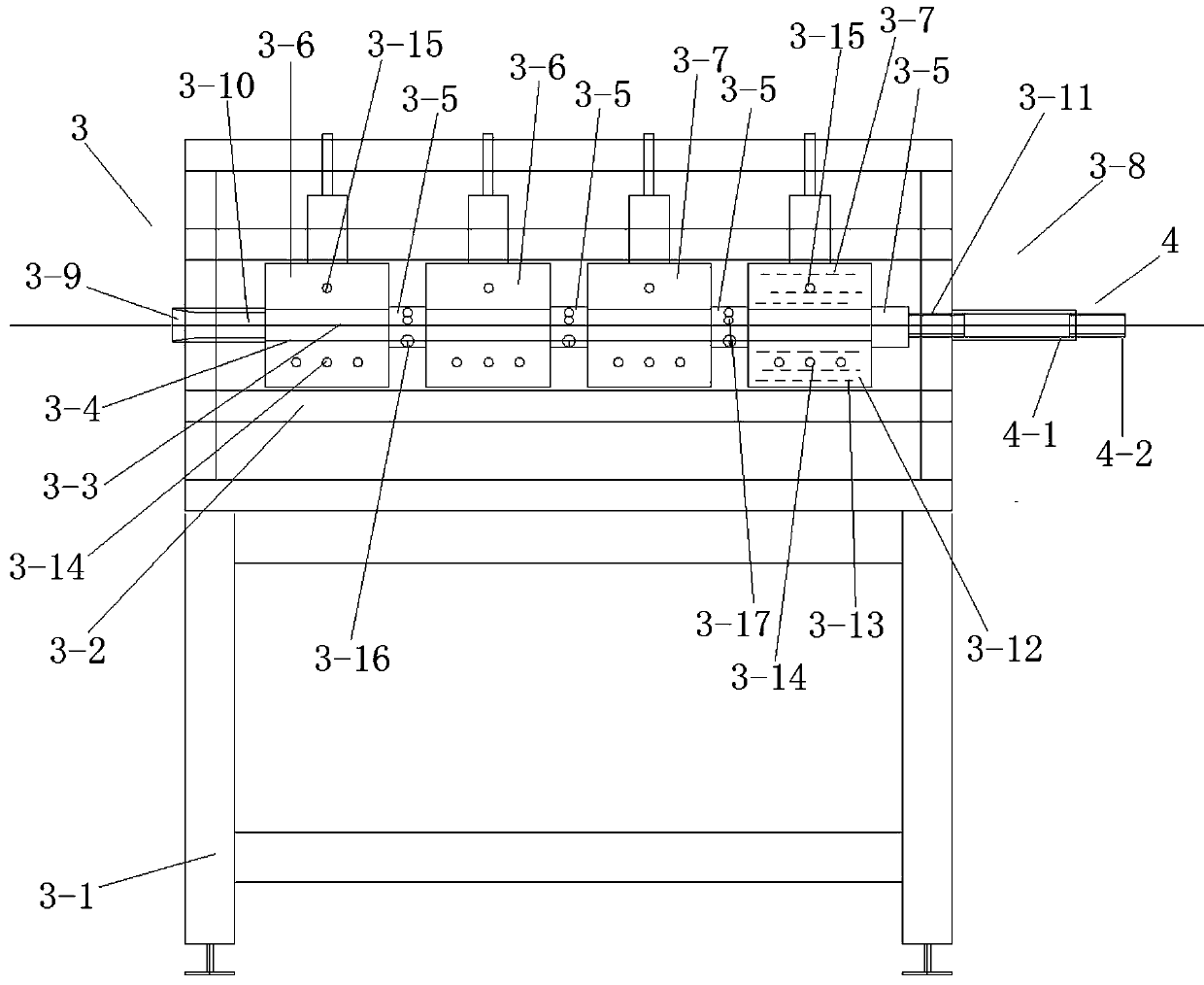

[0056] Refer to attached Figure 1-6 , a production line of glue-free fiber bar stock includes a glue-free fiber bundle constant tension unwinding device 1, a glue-free fiber bundle pulling device 2, a glue-free fiber bar stock heat setting machine 3, a glue-free fiber bar stock traction cutting machine 5, and an accurate Solidify and form the combination mold 4.

[0057] The glue-free fiber constant tension unwinding device 1 is equipped with a glue-free fiber bundle traction device 2 at the front, and the glue-free fiber bundle heat-setting machine 3 is installed at the front of the glue-free fiber bundle traction device 2 . Glue-free fiber bar heat-setting machine 3 front portion is equipped with glue-free fiber bar traction cutting machine 5, precise forming combination mold 4 is installed in glue-free fiber bar heat-setting machine 3 front portion glue-free fiber bar 7 output ends.

[0058] Glue-free fiber bundle constant tension unwinding device 1 includes frame 1-1, to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com