Wet type coal dust removing experimental system

An experimental system, wet dedusting technology, applied in the direction of using liquid separation agent, testing of machine/structural components, instruments, etc., can solve the problems of high water content in coal and poor dedusting effect, so as to improve the dedusting effect and ensure the authenticity , improve the effect of the simulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

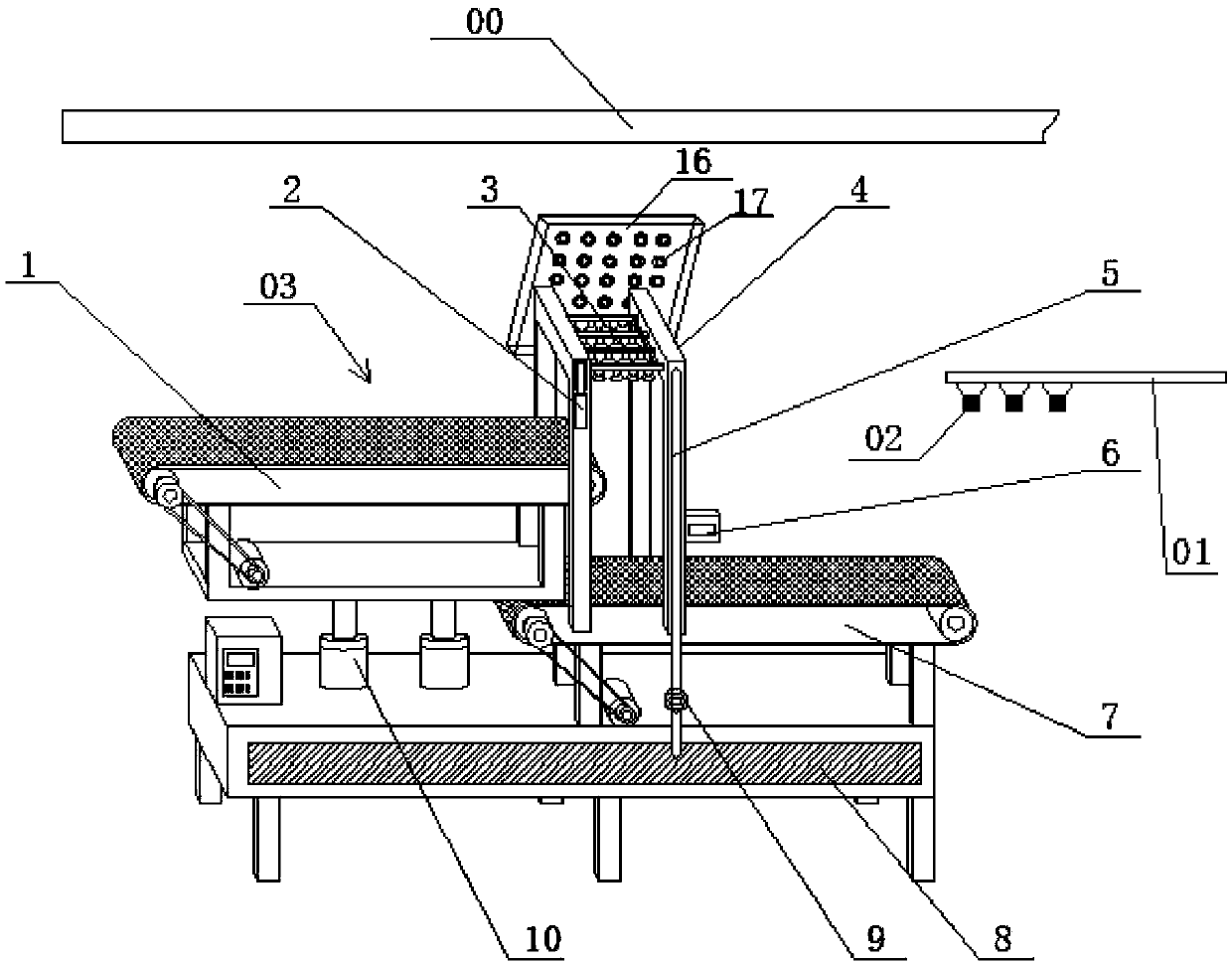

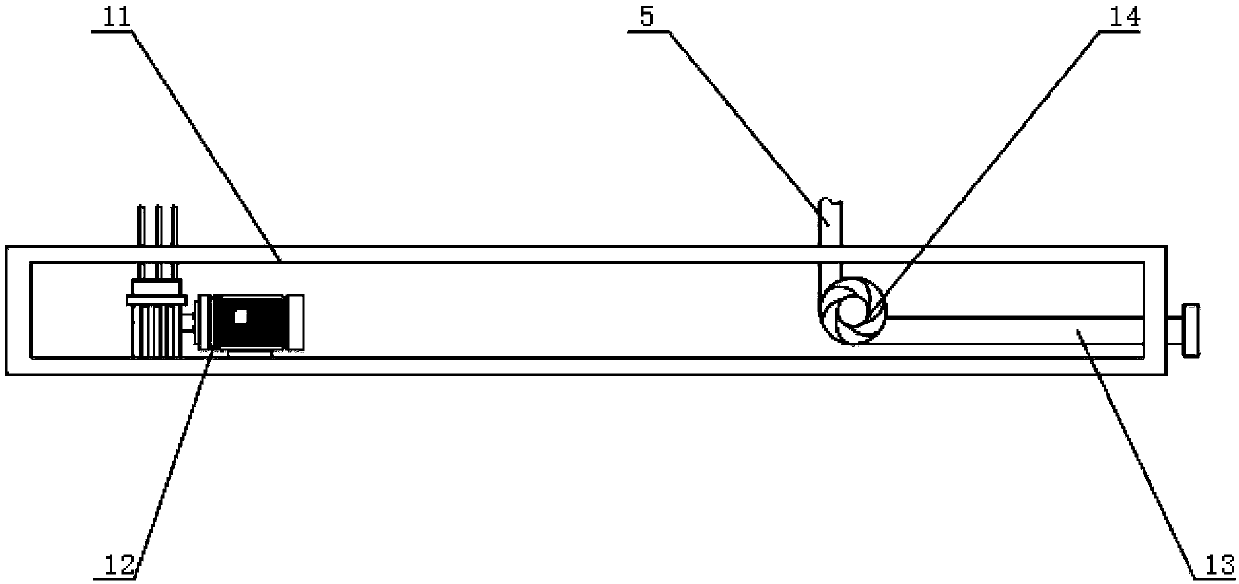

[0032] see Figure 1~4 , in an embodiment of the present invention, a wet coal dust removal experimental system includes a protective seat cover 00, a sensor seat 01, a coal dust detection sensor group 02 and a dust removal experimental assembly 03, characterized in that,

[0033] The protective seat cover 00 is formed as a roadway structure with a roadway cavity inside, and extends along the extension direction of the roadway cavity to the roadway;

[0034] The dust removal experiment assembly 03 is located in the roadway cavity of the protective seat cover 00;

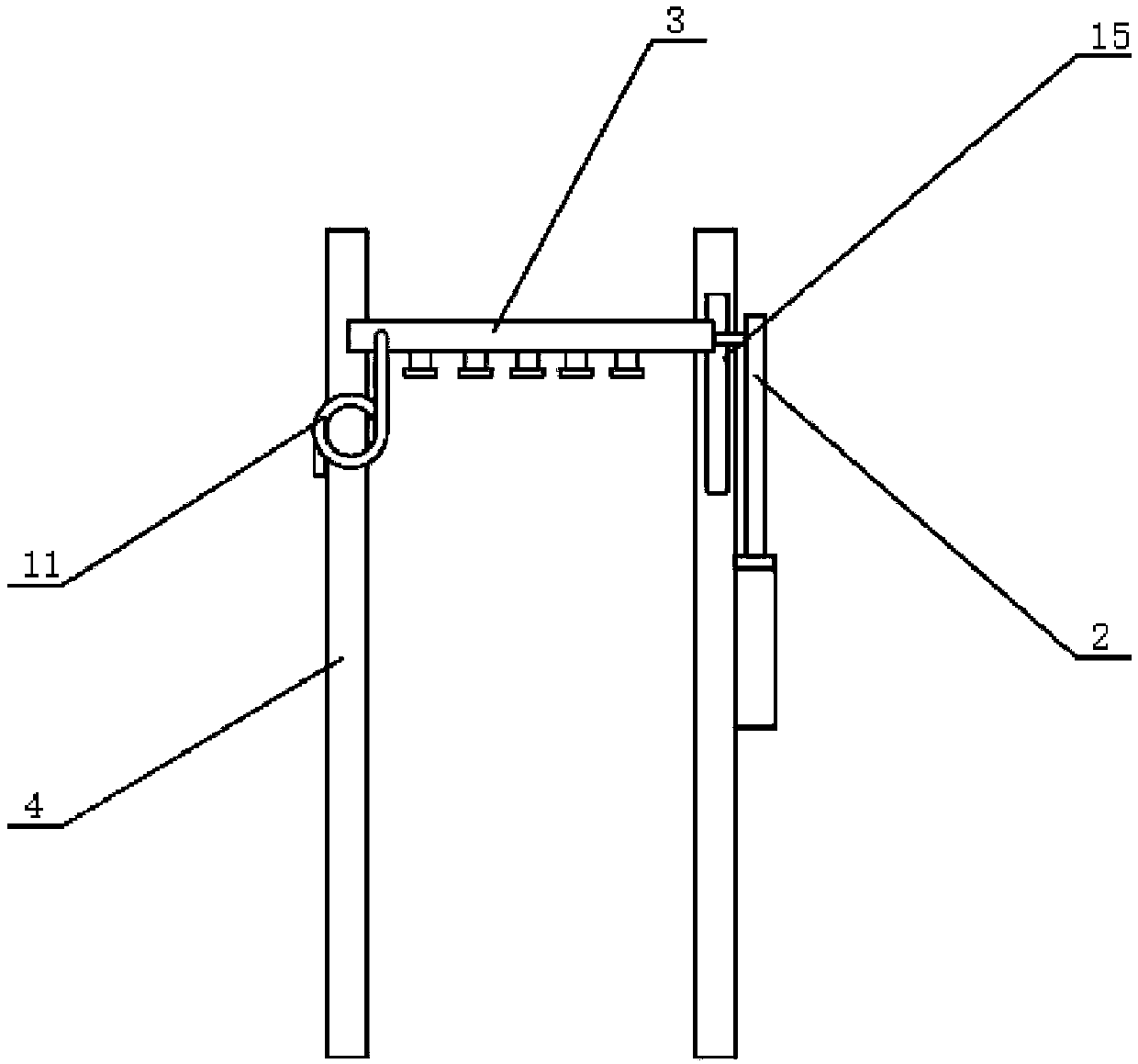

[0035] The dust removal experiment assembly 03 includes a coal dust generation assembly and a wet dust removal assembly, and the wet dust removal assembly is arranged above the coal dust generation assembly; and the height of the wet dust removal assembly is adjustable;

[0036] The wet dust removal assembly includes a top dust removal spray assembly and a side dust removal spray assembly, the side dust removal spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com