A machine vision-based material granularity on-line detection method

A technology of machine vision and detection method, which is applied in particle size analysis, instruments, analysis materials, etc., can solve the problems of large particle size measurement error and inaccurate image segmentation, and achieve the effect of eliminating particle size measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

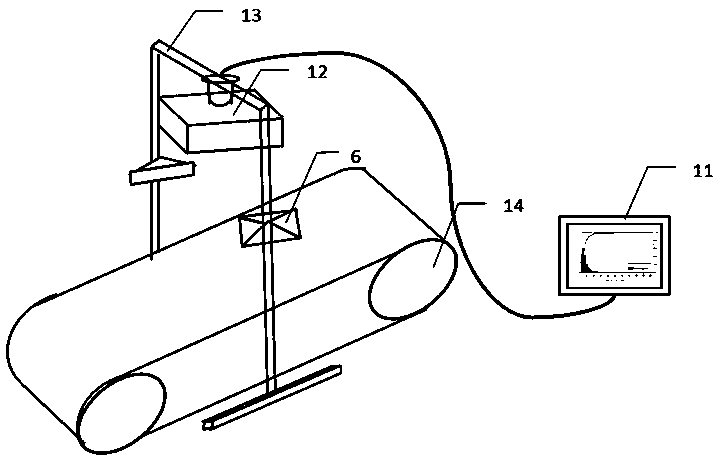

[0022] Taking coal gangue on the conveyor belt as an example below, in conjunction with the accompanying drawings, the machine vision-based material particle size online detection technology and device of the present invention are further described as follows:

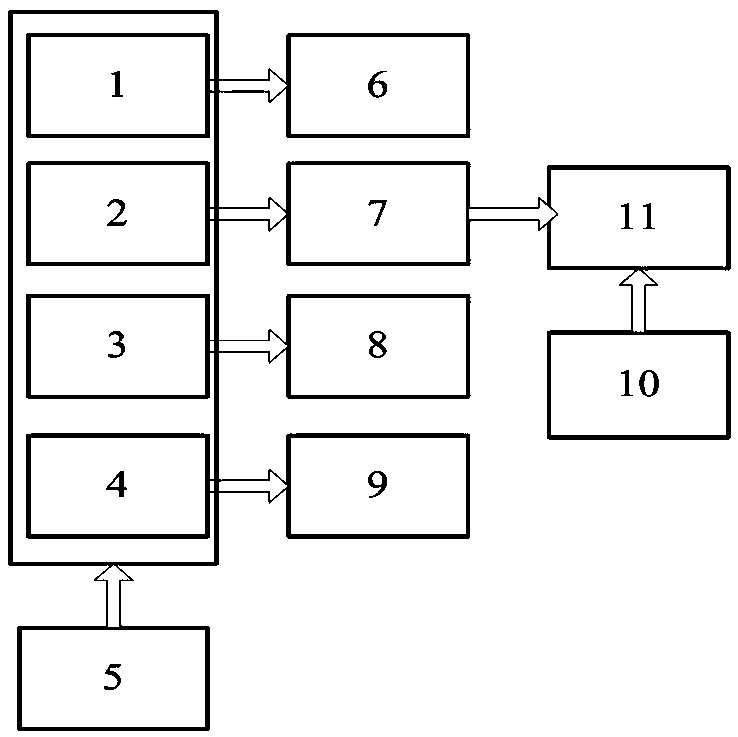

[0023] The on-site installation schematic diagram in the device of the present invention is as figure 2 , including industrial camera 7, ranging module 10, first time relay 1, second time relay 2, third time relay 3, fourth time relay 4, fifth time relay 5 (time controller), sprinkler 8 and the chassis 12 of the wiper 9 are suspended above the conveyor belt 14 by the bracket 13, and two 500W LED lighting lamps 6 are fixed on both sides of the bracket 13. The specific operation process is as follows: the first time relay 1 controls the LED light 6 to turn on; 5 seconds later, the second time relay 2 triggers the camera 7 to collect an image of the material on the conveyor belt 14; after another 5 seconds, the first tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com