Efficient horizontal solid-liquid separation equipment

A solid-liquid separation, horizontal technology, applied in the field of high-efficiency horizontal solid-liquid separation equipment, can solve the problems of low work efficiency, low quality of solid material and liquid material separation, etc., to improve work efficiency, simple device structure, improve The effect of the mass of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

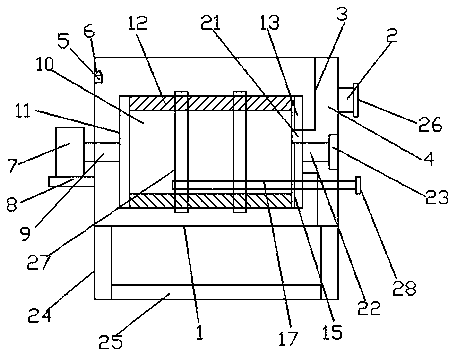

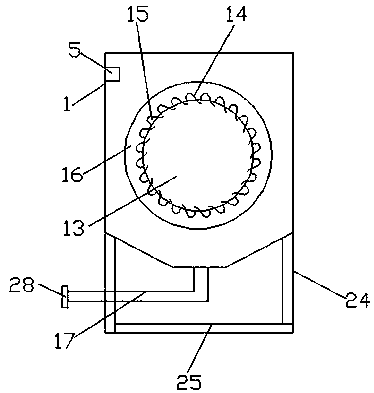

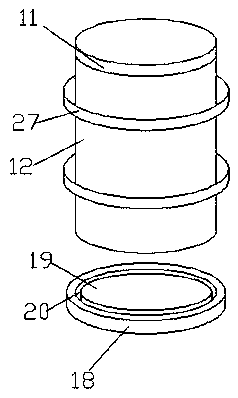

[0026] see Figure 1-3 , according to an embodiment of the present invention, a high-efficiency horizontal solid-liquid separation device includes a main water tank 1, one end of the main water tank 1 is provided with a water inlet pipe 2, and an L baffle 3 is symmetrically provided in the main water tank 1 A water inlet channel 4 is formed between the L baffle plate 3 and the main body water tank 1, and the other end of the main body water tank 1 is provided with a water outlet weir groove 5, and the water outlet weir groove 5 and the main body water tank 1 A groove-shaped water outlet 6 is formed, a drive motor 7 is provided on one side of the main body water tank 1, and a fixing plate 8 is arranged below the drive motor 7, and the fixing plate 8 is fixed on the outer wall of the main body water tank 1. The output end of the driving motor 7 is provided with a rotating shaft 9, and the main water tank 1 is provided with an inertial separation mechanism 10, and the inertial se...

Embodiment 2

[0029] Such as Figure 1-3 As shown, under the main body water tank 1, supporting legs 24 are symmetrically arranged, and a fixed base 25 is arranged between the supporting legs 24; supporting legs 24 are symmetrically arranged under the main body water tank 1, and a fixed base is arranged between the supporting legs 24 25. It can support and fix the main water tank 1. The water inlet pipe 2 is connected with a water inlet weir groove 26; the water inlet pipe 2 is connected with a water inlet weir groove 26, which can facilitate the mixture to flow into the main water tank 1 through the water inlet weir groove 26. A fixing ring 27 is provided outside the separation bucket 12; One end of the return pipeline 17 is provided with a control valve 28; the control valve 28 is provided at one end of the return pipeline 17, which can conveniently control the switch of the return pipeline 17.

[0030]To sum up, with the help of the above technical solution of the present invention, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com