Corn winnowing screening device based on rolling decentralizing technology

A technology of corn kernels and air sieving, which is applied in sieving, solid separation, and separation of solids from solids by air flow, etc. The effect of subsequent processing, uniform corn kernels, and improving the quality of air selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

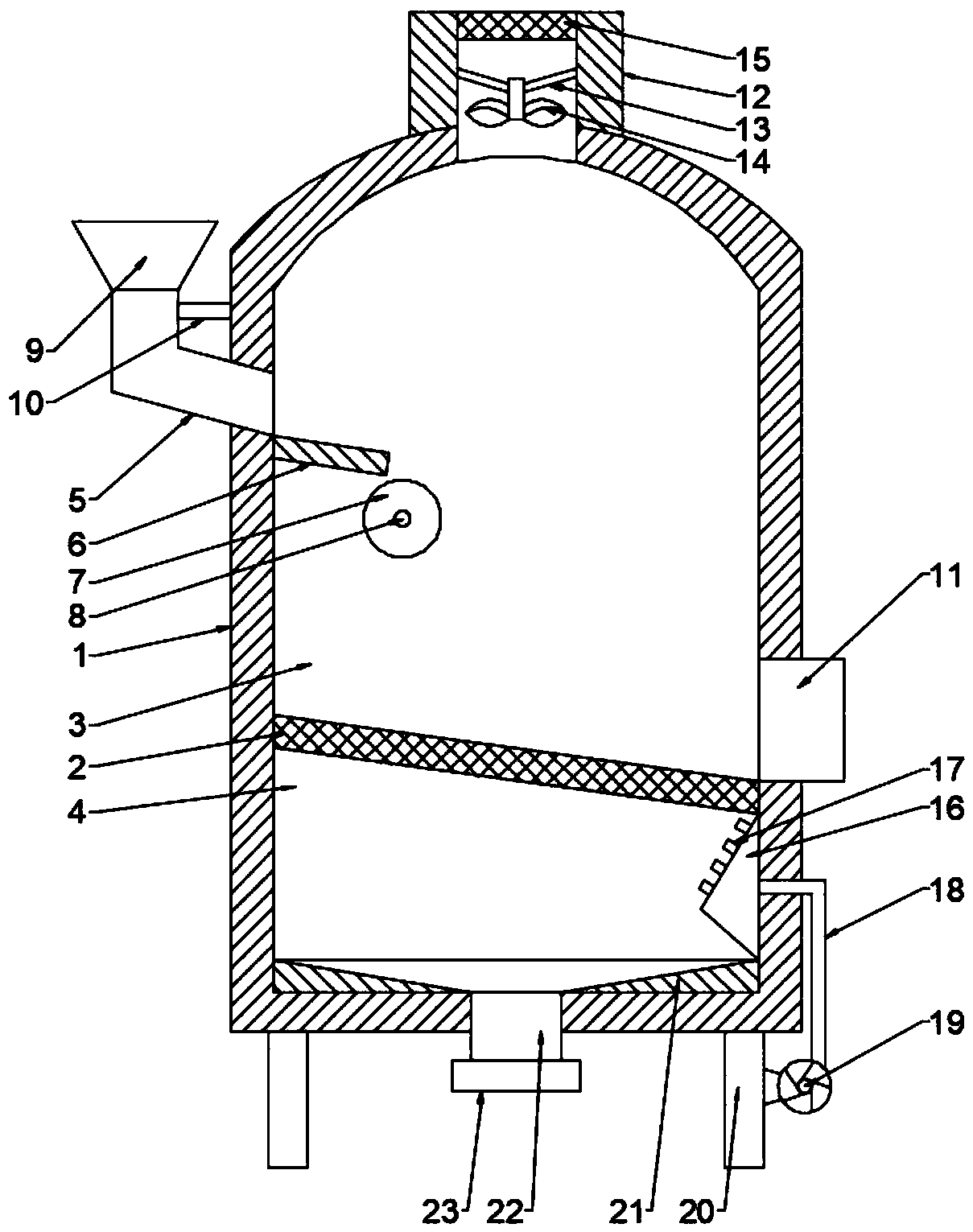

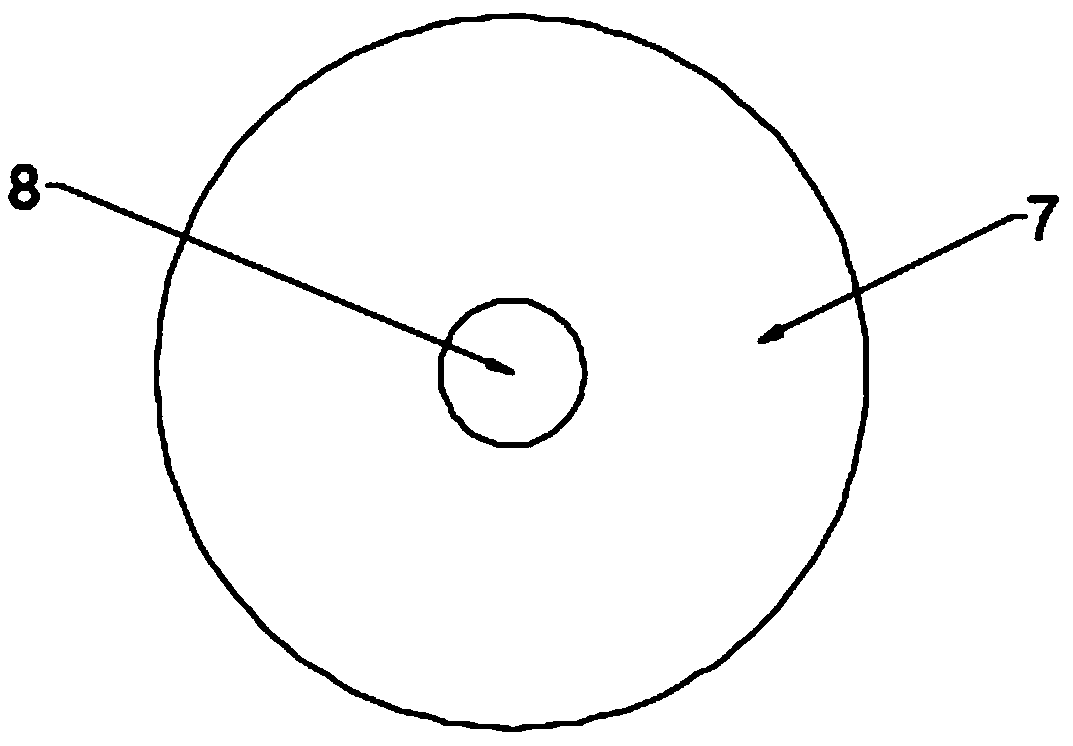

[0026] see Figure 1~3 , a kind of air selection and screening device for corn kernels based on rolling and splitting technology, comprising a tower body 1, a screen 2 is provided at the bottom of the inner cavity of the table body 1, and the screen 2 is arranged obliquely, and the screen 2 The inner cavity of tower body 1 is divided into winnowing chamber 3 and wind chamber 4, and described winnowing chamber 3 is arranged on the top of wind chamber 4, and the top of the left end of winnowing chamber 3 connects feeding pipe 5 through, and the top of winnowing chamber 3 The left wall of the inner cavity is provided with a deflector 6 matched with the feed pipe 5, and the deflector 6 is arranged obliquely. A grading roller 7, the grading roller 7 is connected to the inner wall of the winnowing chamber 3 through a rotating shaft 8, and one end of the rotating shaft 8 runs through the tower body 1 and is fixedly connected to the motor outside the machine (not shown in the figure)....

Embodiment 2

[0028] This embodiment is a further elaboration on the basis of Embodiment 1. The feed pipe 5 is a V-shaped structure, and one side end of the incoming pipe 5 is fixedly connected to the tower body 1 through a connecting rod 10. By setting the connecting rod 10 , used to improve the stability of the feeding pipe 5; the top of the feeding pipe 5 is connected to the feeding hopper 9, and the corn grains are added through the feeding hopper 9, and enter the tower body 1 through the feeding pipe 5.

[0029] The bottom end of the right side of the inner cavity of the air separation chamber 3 is connected to the first discharge pipe 11, and the first discharge pipe 11 corresponds to the lowest end of the screen 2, and the corn kernels are blown in the wind separation chamber 3. After being selected, it falls on the sieve 2 and slides down along the sieve 2. The large-grained corn kernels slide down with the sieve 2, and finally are discharged through the first discharge pipe 11, and ...

Embodiment 3

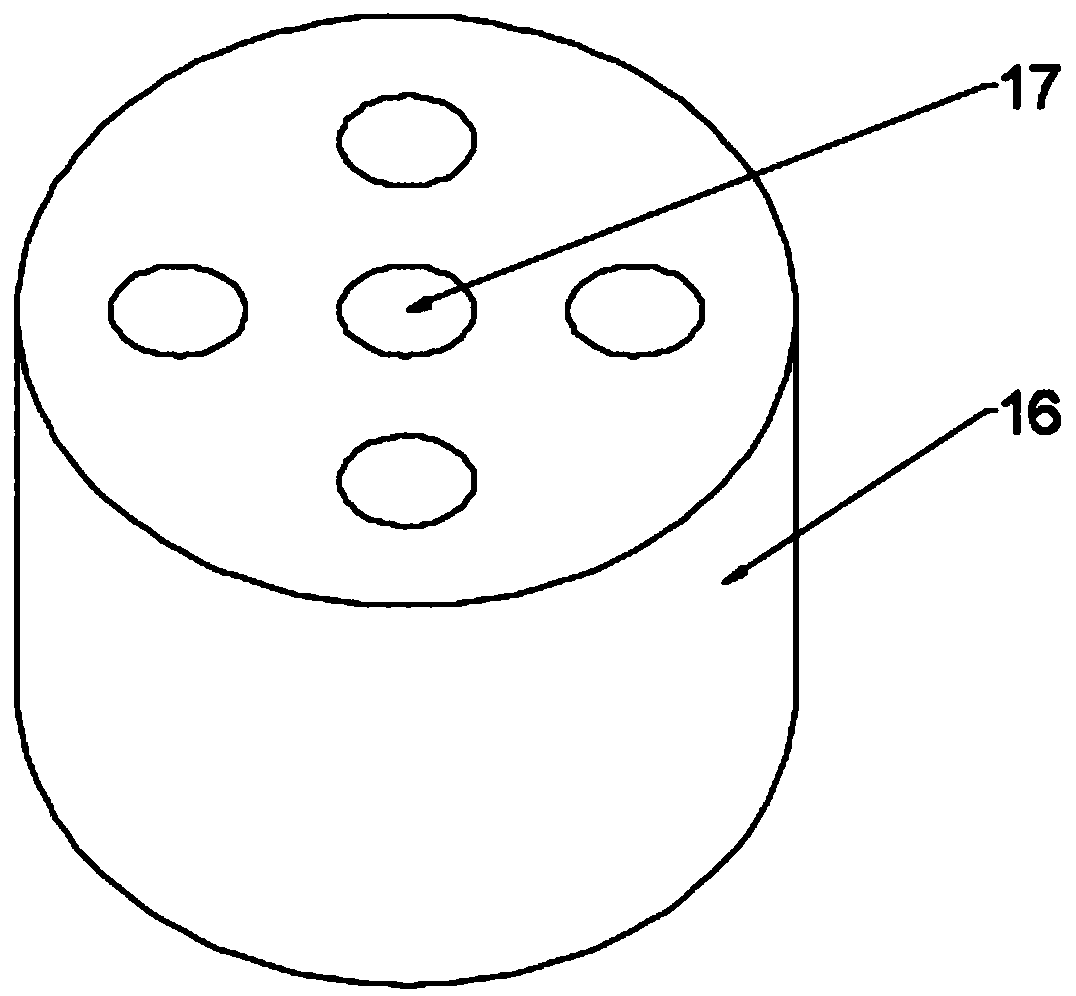

[0032] This embodiment is a further elaboration on the basis of Embodiment 1. The bottom edge of the tower body 1 is evenly provided with a number of legs 20, and a fan 19 is arranged on one of the legs 20, and the fan 19 passes through The air pipe 18 is connected with the air blowing device 16, and provides sufficient wind for the air blowing device 16 through the fan 19, so as to ensure the continuity of winnowing work and improve the processing efficiency.

[0033] The middle part of the bottom end of the wind chamber 4 is connected to the second discharge pipe 22, and the bottom wall of the inner cavity of the wind chamber 4 is provided with a diversion bucket 21 matched with the second discharge pipe 22. The second discharge pipe The bottom end of 22 is sheathed with sealing cover 23, and the small particle corn grain that sieve cloth 2 screens enters the second discharge pipe 22 and discharges under the effect of diversion funnel 21.

[0034] The top of the winnowing ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com