Method for machining high-precision holes of carbon fiber sandwich-aluminum alloy laminated materials

A processing method and technology of aluminum alloy layer, applied in the field of mechanical processing, can solve the problems of low efficiency, reduced hole quality and precision, prone to flutter, etc., and achieve the effects of reducing manufacturing cost, ensuring processing quality, and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

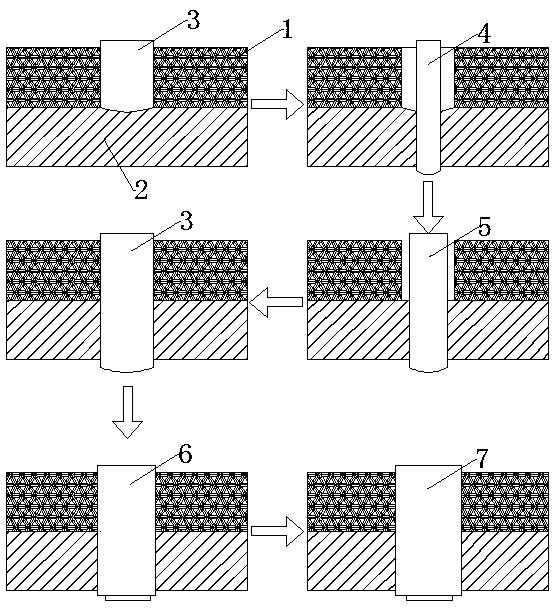

[0024] The present invention is realized through the following technical solutions, as figure 1 As shown, a carbon fiber sandwich-aluminum alloy laminated material high-precision hole processing method, the carbon fiber sandwich and the aluminum alloy joint are assembled together through a tooling frame, and then layered drilling is performed according to different materials, and the same material Different tool combinations are selected in the area, and the method of step drilling and reaming is adopted to realize the processing of high-precision holes in carbon fiber sandwich-aluminum alloy laminated materials.

[0025] It should be noted that, through the above improvements, the limitation of drilling from the carbon fiber sandwich layer 1 due to the processing conditions has been broken through the method of layering and step drilling and reaming, and the tearing of the carbon fiber sandwich layer 1 hole has been avoided. Quality problems such as damage and out-of-toleranc...

Embodiment 2

[0028] This embodiment is further optimized on the basis of the above embodiments, such as figure 1 As shown, it specifically includes the following steps:

[0029] Step S1: Assemble the carbon fiber sandwich material and the aluminum alloy joint through the tooling frame, and fix it on the machine tool table;

[0030] Step S2: Select the drill bit 3 to make the initial hole of the carbon fiber sandwich layer in the carbon fiber sandwich layer 1; the initial hole of the carbon fiber sandwich layer is a blind hole; the diameter of the initial hole is D C , the diameter of the final hole formed after processing is D Z .

[0031] Step S3: According to the size of the final hole of the carbon fiber sandwich layer 1, different tool combinations are selected, and the hole of the aluminum alloy layer is processed to the same diameter as the initial hole of the carbon fiber sandwich layer by step drilling;

[0032] Step S4: The carbon fiber sandwich layer 1 and the aluminum alloy l...

Embodiment 3

[0042] This embodiment is the best embodiment of the present invention, as figure 1 As shown, a carbon fiber sandwich-aluminum alloy laminated material high-precision hole processing method specifically includes the following steps:

[0043] Step S1: Assemble the carbon fiber sandwich material and the aluminum alloy joint through the tooling frame, and fix it on the machine tool table;

[0044] Step S2: Select the drill bit 3 to make the initial hole of the carbon fiber sandwich layer in the carbon fiber sandwich layer 1; the initial hole of the carbon fiber sandwich layer is a blind hole; the diameter of the initial hole is D C , the diameter of the final hole formed after processing is D Z .

[0045]The step S2 specifically refers to: in the drilling of the initial hole of the carbon fiber sandwich layer, the initial hole diameter D C and end hole diameter D Z Satisfy between: 0.6mm≤(D Z -D C )≤1mm; and the depth L at the drill shoulder P and the thickness d of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com