Production process of VCM motor component carrier

A production process and carrier technology, which is applied to the production process field of VCM motor component carrier, can solve the problems of reducing the running accuracy of the motor and the low precision of the screw thread.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

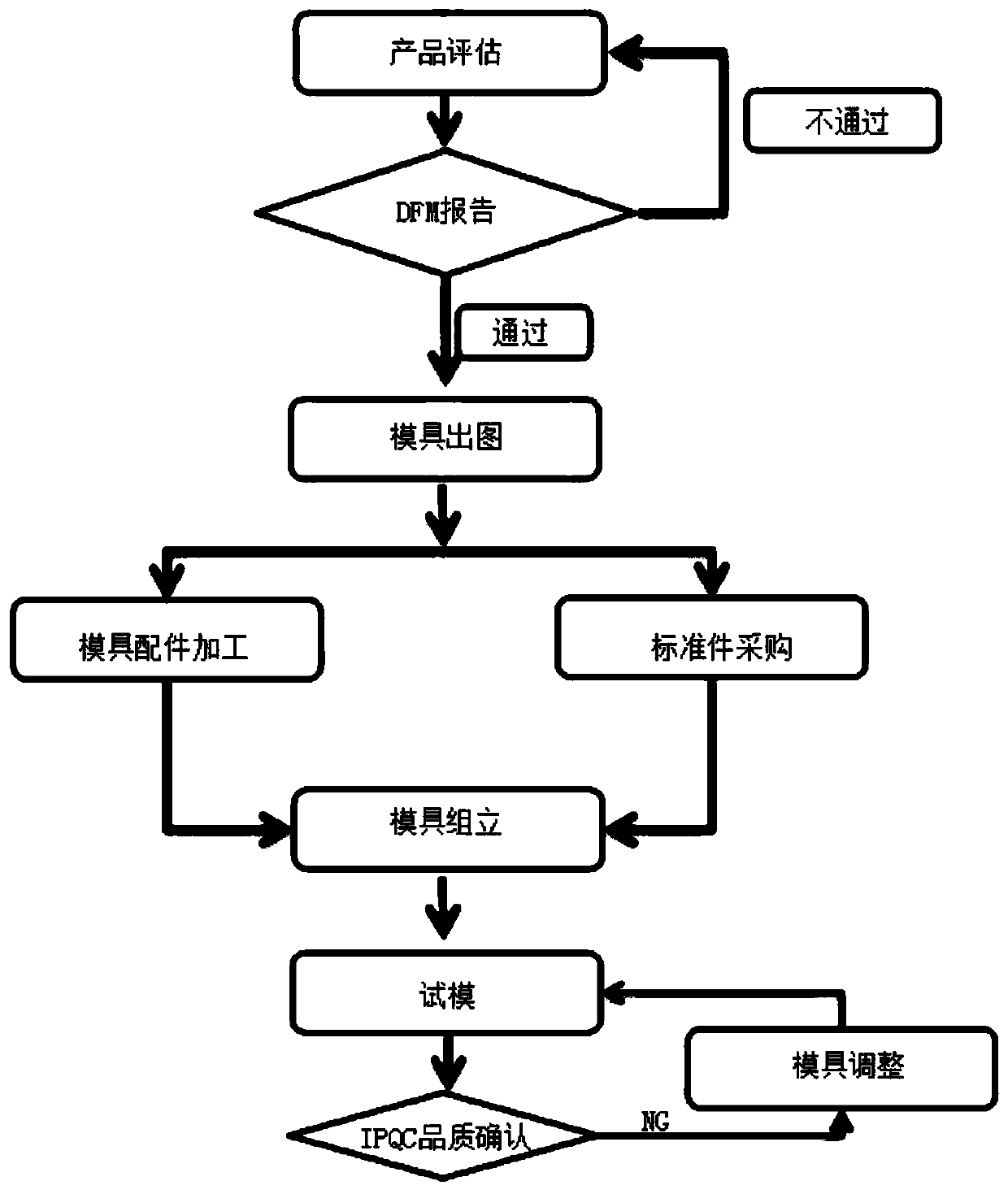

[0020] Such as figure 1 As shown, a production process of a VCM motor component carrier, the steps are as follows, first evaluate the motor carrier, pass the DFM report, then draw the mold drawing, carry out the assembly and production of the mold, and then match the mold with the injection molding machine for trial Injection molding the motor component carrier and drying;

[0021] Among them, the injection molding machine with a sudden change in the form of the screw is used, and its speed is 20r / min; the form of the nozzle is self-locking, and the temperature is 300°C; the temperature of the barrel: 260°C in the front, 280°C in the middle, and 260°C in the rear ℃; mold temperature is 90°C; injection pressure is 70MPa; holding pressure is 300MPa; total cycle is 10 seconds, of which injection time is 1S; holding time is 1 second; cooling time is 5 seconds; The drying temperature is 120°C and the drying time is 4 hours;

[0022] In order to ensure the processing accuracy of t...

Embodiment 2

[0025] A production process of VCM motor component carrier, the steps are as follows, first evaluate the motor carrier, pass the DFM report, then draw the mold drawing, carry out the assembly and production of the mold, and then cooperate with the mold and the injection molding machine to carry out the test mold injection molding motor Part carrier and drying;

[0026] Among them, the injection molding machine with a sudden change in the form of the screw is used, and its speed is 50r / min; the form of the nozzle is self-locking, and the temperature is 310°C; the temperature of the barrel: 290°C in the front, 290°C in the middle, and 280°C in the rear. ℃; mold temperature is 90°C; injection pressure is 110MPa; holding pressure is 600MPa; total cycle is 20 seconds, of which injection time is 3S; holding time is 5 seconds; The temperature is 140°C, and the time is 6 hours; in order to ensure the processing accuracy of the thread, the mold is made of high-hardness alloy steel mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com