Surface-decorated acrylic plate and surface decorating method thereof

A surface decoration and acrylic board technology, applied in decorative arts, special decorative structures, etc., can solve the problems of difficult mass production and high worker requirements, and achieve the effect of not easy to detach, good bonding ability, and easy to promote.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

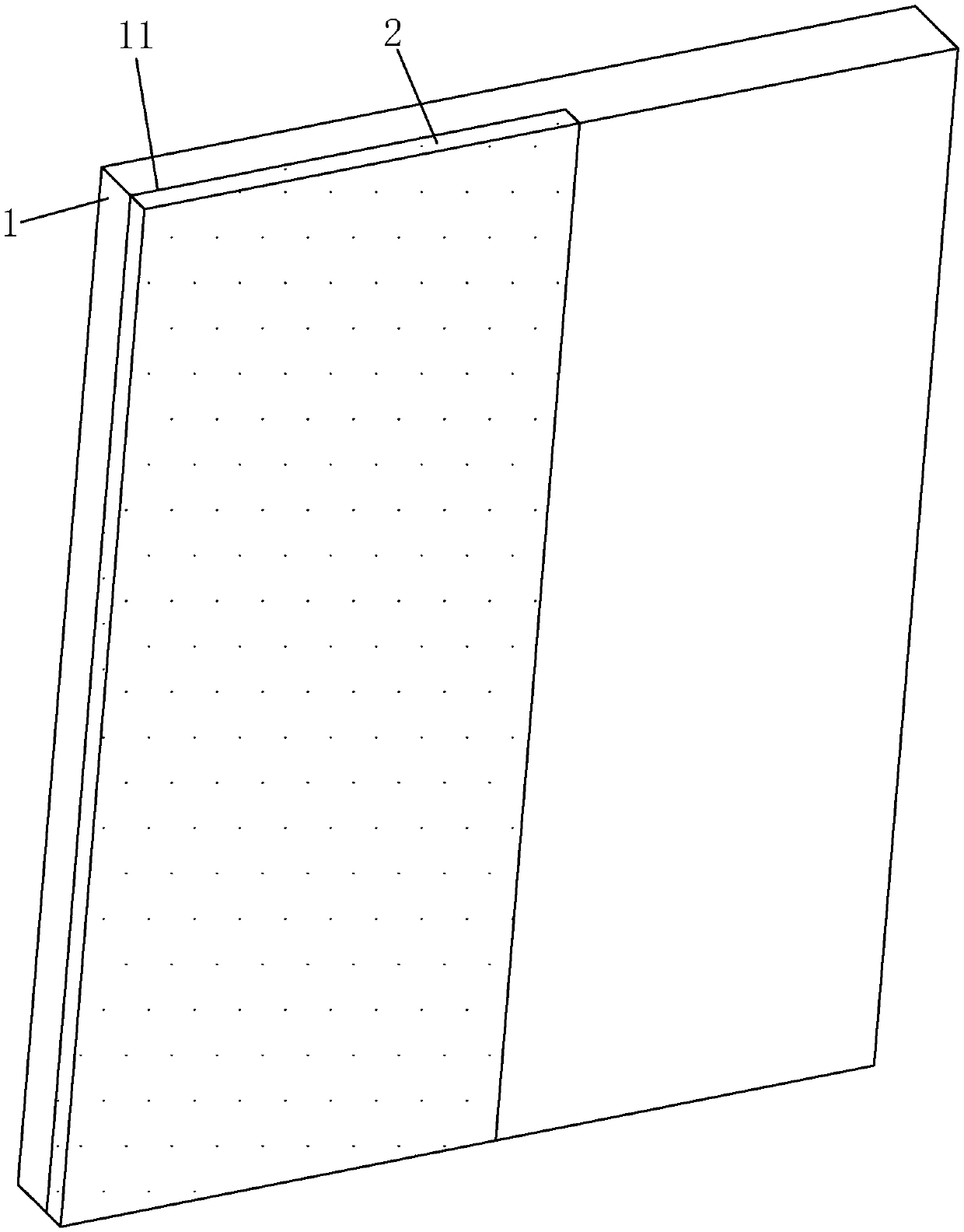

[0063] A surface decorated acrylic sheet such as figure 1 As shown, the board body 1 is included, and the board body 1 is provided with a cuboid-shaped groove 11. The groove 11 is filled with decorative glue, and the glue layer 2 is formed after the decorative glue dries. The points in the glue layer 2 are doped gold dust.

[0064] The composition and volume ratio of decorative glue are as follows:

[0065] Acrylic adhesive 100ml

[0066] Benzoyl Peroxide 5ml

[0067] Acrylic Thinner 10ml

Embodiment 2

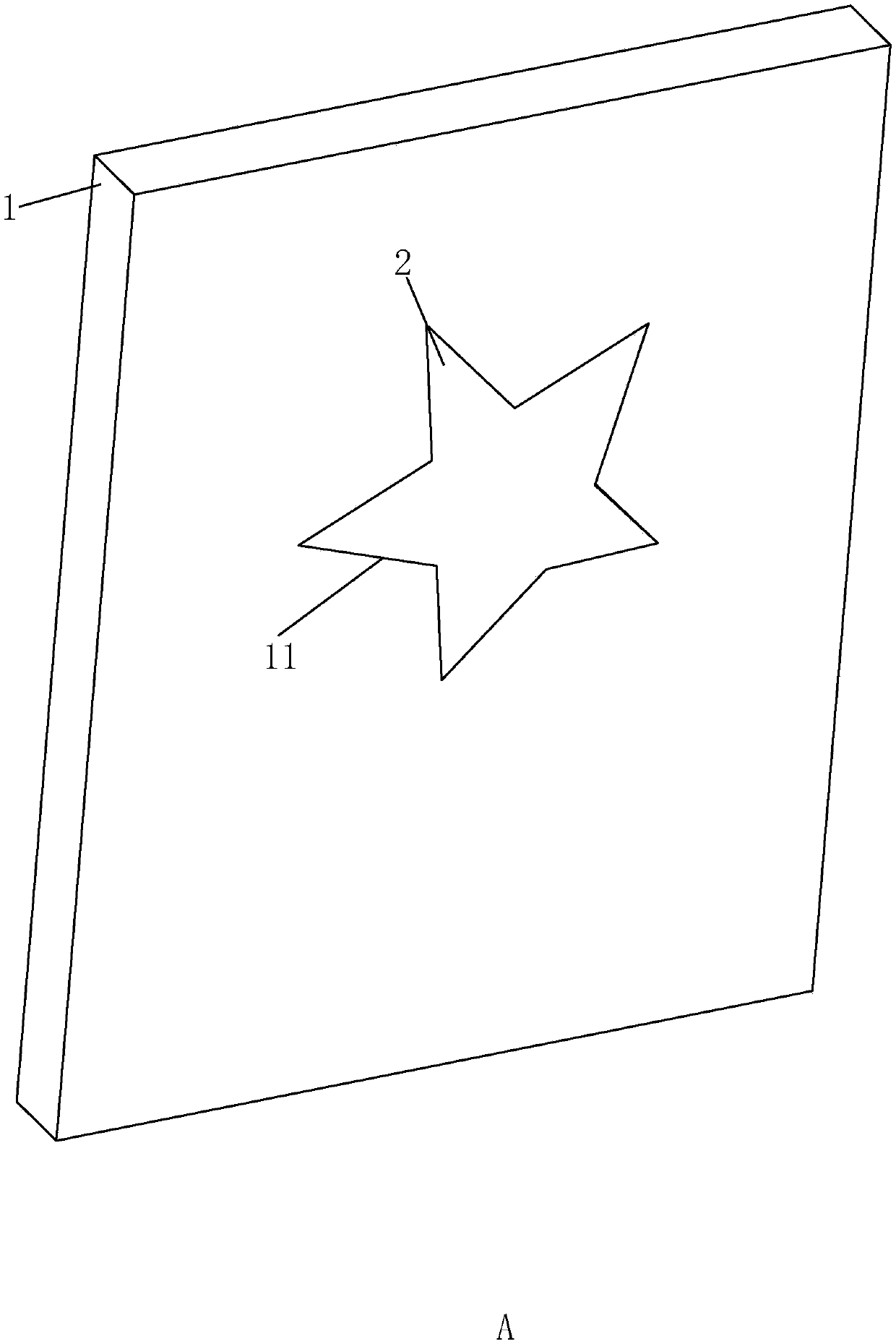

[0069] A surface decorated acrylic sheet such as figure 2 As shown, the board body 1 is included, and the board body 1 is provided with a five-pointed star-shaped groove 11, and the groove 11 is filled with decorative glue, and the glue layer 2 is formed after the decorative glue dries.

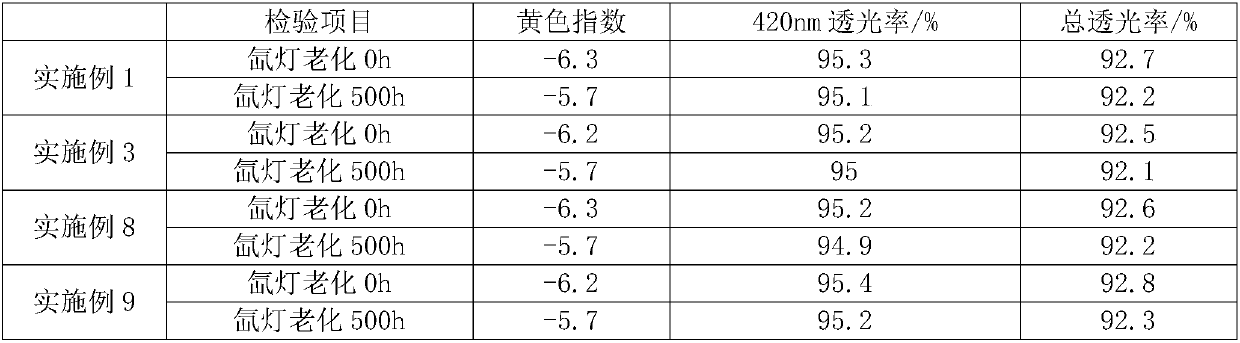

[0070] The difference between Examples 3-10 and Comparative Examples 1-7 is that the volume fraction of each component of the decorative glue is different, see the table below for details.

[0071]

acrylic thinner

Example 1

100

5

10

Example 3

100

5

11

Example 4

100

5.5

11

Example 5

90

4

9

Example 6

90

5

9

Example 7

90

5

10

Example 8

110

5.5

12

Example 9

110

6

11

Example 10

110

5

11

Comparative example 1

100

5

0

Comparative example 2

100

0

10

Comparative examp...

Embodiment 11

[0093] The surface decoration method of the surface-decorated acrylic plate, the difference between embodiment 11 and embodiment 9 is that the acrylic decoration glue is doped with pigment or gold powder before step 1. Decorative glue is a liquid, which can be evenly mixed with pigments and gold powder, and the decorative effect is better, and it also enriches the types of decorations, and is more likely to be loved by consumers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com