Dechlorinating agent and preparation and use methods thereof

A technology of dechlorination agent and surfactant, which is applied in the direction of chemical instruments and methods, water pollutants, electrochemical water/sewage treatment, etc., can solve the problems of high dechlorination cost and many dechlorination process procedures, and improve the dechlorination process. Chlorine effect, high dechlorination efficiency, effect of fewer steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A dechlorination agent, including lead compound and silver compound, by mass percentage, the lead content is more than 27.5%, the silver content is 0%, and the rest is hydroxide and crystal water.

[0024] The preparation method comprises the following steps:

[0025] (1) Add silver nitrate in proportion to lead oxide to obtain initial mixture:

[0026] (2) Add sulfuric acid to the primary mixture prepared in step (1) to adjust to weak alkalinity, pH ≈ 7.5, to obtain a dechlorination agent, which is made into a 180-mesh powder.

[0027] The method of use includes the following steps:

[0028] (1) adding the dechlorination agent into water to obtain a mixed solution;

[0029] (2) Add polyethylene glycol distearate to the mixed solution obtained in step (1), and stir evenly to obtain a semi-stable suspension, which can be used for dechlorination.

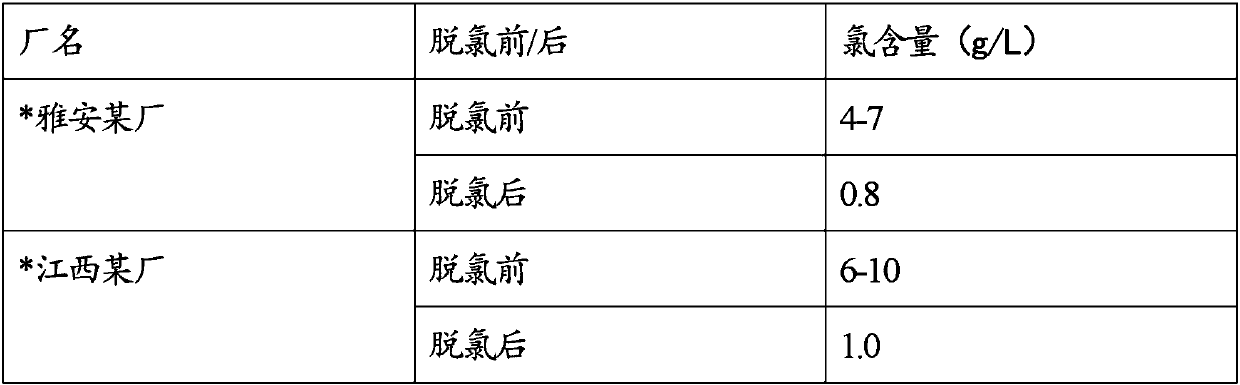

[0030] Test detection: pour the semi-stable suspension used for dechlorination prepared in this example into the waste aci...

Embodiment 2

[0036] A dechlorination agent, including lead compound and silver compound, by mass percentage, the lead content is ≥ 27.5%, the silver content is 0.5%, and the rest is hydroxide and crystal water.

[0037] The preparation method comprises the following steps:

[0038] (1) Add silver nitrate in proportion to lead tetroxide to obtain initial mixture;

[0039] (2) Add sulfuric acid to the primary mixture prepared in step (1) to adjust to weak alkalinity, pH ≈ 7.5, to obtain a dechlorination agent, which is made into a 180-mesh powder.

[0040] The method of use includes the following steps:

[0041] (1) adding the dechlorination agent into water to obtain a mixed solution;

[0042] (2) Add polyethylene glycol distearate to the mixed solution obtained in step (1), and stir evenly to obtain a semi-stable suspension, which can be used for dechlorination.

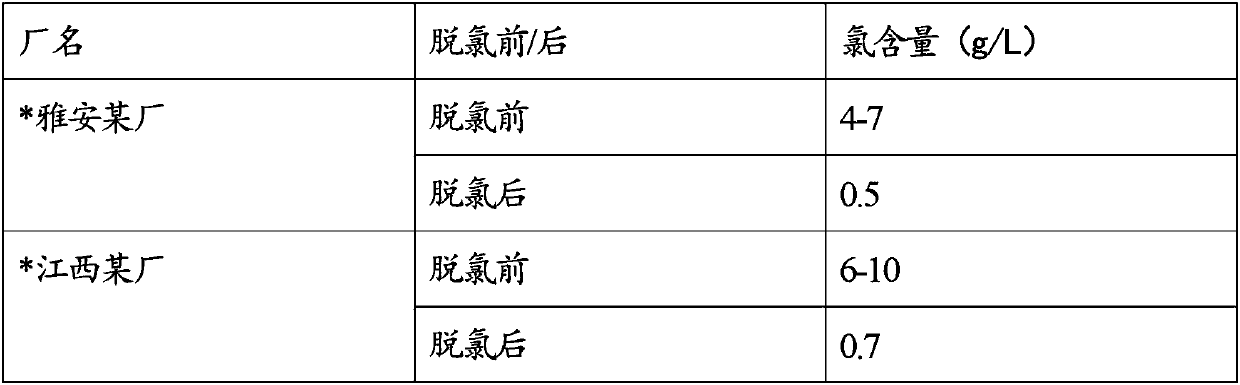

[0043] Test detection: pour the semi-stable suspension used for dechlorination prepared in this example into the waste acid ...

Embodiment 3

[0049] A dechlorination agent, including lead compound and silver compound, in terms of mass percentage, the lead content is more than 27.5%, the silver content is 0.8%, and the rest is hydroxide and crystal water.

[0050] The preparation method comprises the following steps:

[0051] (1) Add silver nitrate in proportion to lead sulfate to obtain initial mixture;

[0052] (2) Add sulfuric acid to the initial mixture prepared in step (1) to adjust to weak alkalinity, pH ≈ 7.5, to obtain a dechlorination agent, which is made into a 220-mesh powder.

[0053] The method of use includes the following steps:

[0054] (1) adding the dechlorination agent into water to obtain a mixed solution;

[0055] (2) Add polyethylene glycol distearate to the mixed solution obtained in step (1), and stir evenly to obtain a semi-stable suspension, which can be used for dechlorination.

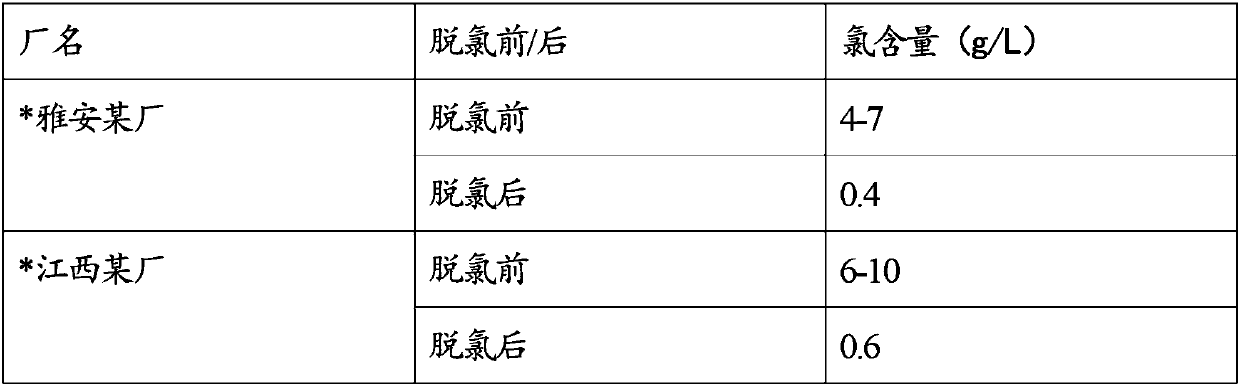

[0056] Test detection: pour the semi-stable suspension used for dechlorination prepared in this example into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com