Die fixing mechanism of pressing machine

A technology of fixing mechanism and pressing machine, which is applied in blowing glass forming machine, glass production, etc. It can solve the problems of low efficiency and unqualified prototype, and achieve the effects of easy demoulding, improved pressing quality, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

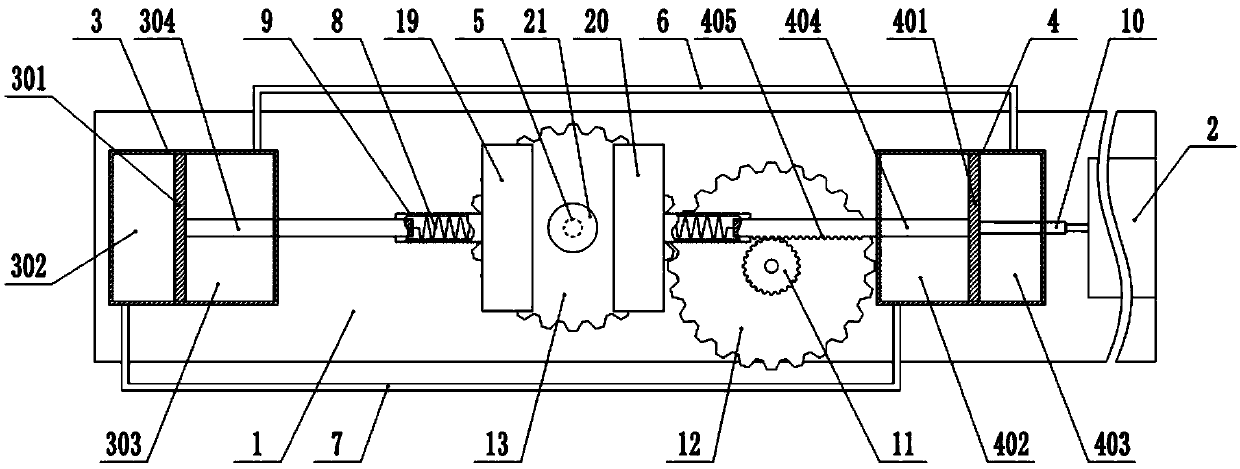

[0027] The embodiment is basically as figure 1 Shown: the mold fixing mechanism of the pressing machine, including the workbench 1, the cylinder 2 and the first cylinder 3 and the second cylinder 4 arranged beside the mold, the mold includes a left movable mold 19, a right movable mold 20 and a bottom mold 21, Form cavity when left movable mold 19, right movable mold 20 and bottom mold 21 close molds. The workbench 1 is rotatably connected with a vertically arranged first rotating shaft 5 , and the top end of the first rotating shaft 5 is fixedly connected with the bottom mold 21 . The first cylinder body 3 is arranged on the left side of the left movable mold 19 , and the second cylinder body 4 is arranged on the right side of the right movable mold 20 .

[0028] The first cylinder 3 and the second cylinder 4 are respectively slidingly connected with a first piston 301 and a second piston 401, and the first piston 301 divides the first cylinder 3 into an independent first ch...

Embodiment 2

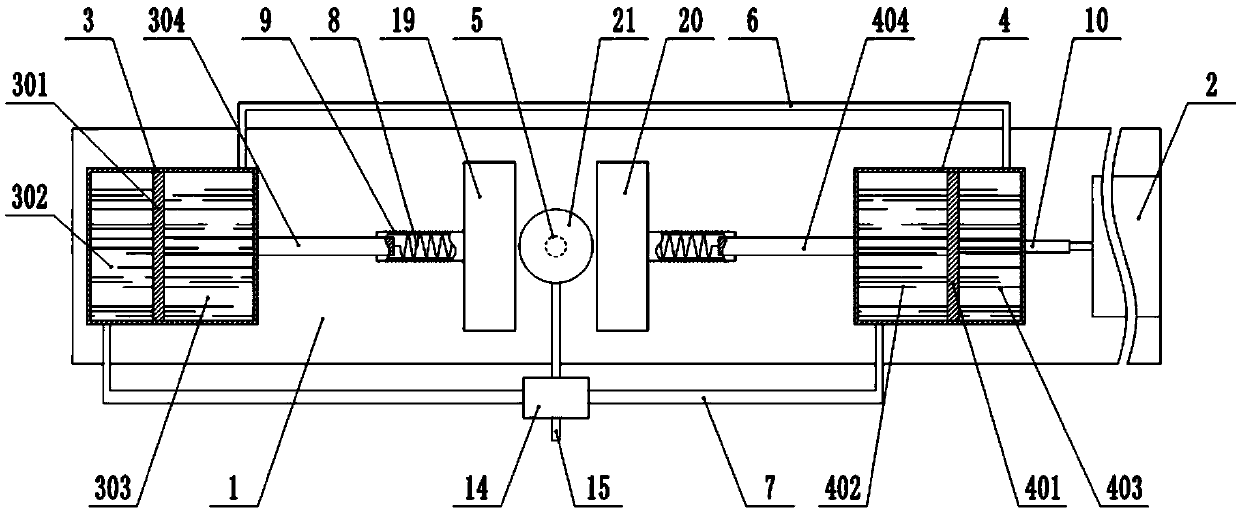

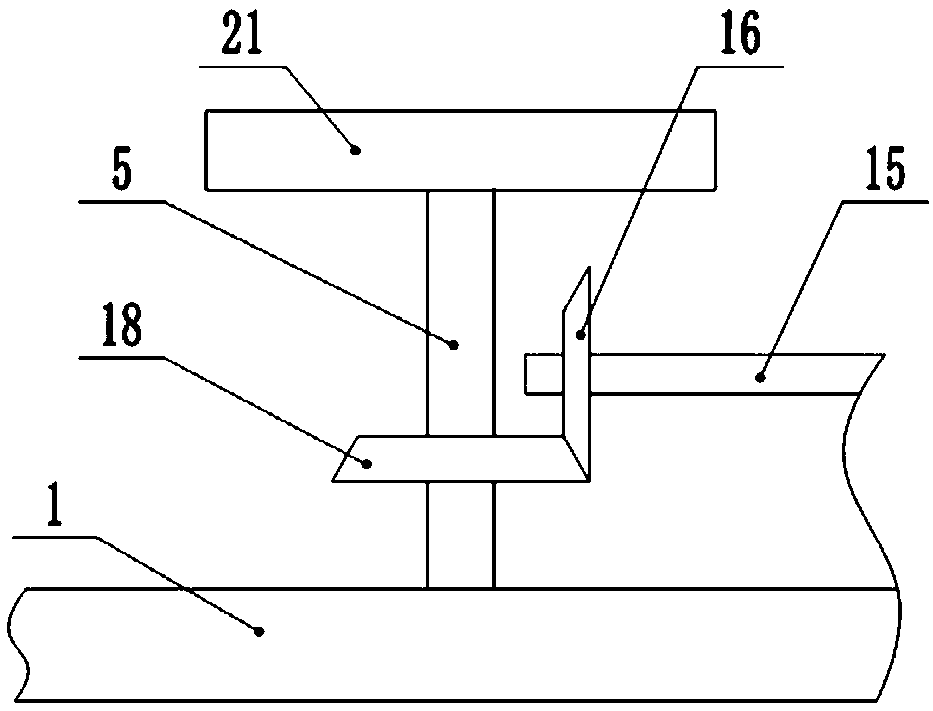

[0038] This embodiment differs from Embodiment 1 in that: figure 2 , image 3 and Figure 4 As shown, the first chamber 302, the second chamber 303, the third chamber 402 and the fourth chamber 403 are all filled with liquid, and in this embodiment, the liquid is tap water. The middle part of the second pipeline 7 communicates with a drive chamber 14, and the drive chamber 14 is rotatably connected with a second rotating shaft 15 arranged horizontally. The second rotating shaft 15 is coaxially fixed with a first bevel gear 16 and a plurality of toggle plates 17. 5. The second bevel gear 18 is fixedly installed coaxially, and the second bevel gear 18 meshes with the first bevel gear 16. The toggle plate 17 is located in the driving cavity 14, and the lower end of the toggle plate 17 extends into the second bevel gear when rotating. Inside the pipeline 7.

[0039] During specific implementation, when the telescopic end of the cylinder 2 drives the push rod 10 to move to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com