Environmentally-friendly micro cutting fluid and preparation method thereof

A kind of cutting fluid, environmental protection technology, applied in the field of environmental protection micro-cutting fluid and its preparation, can solve the problem of lubrication and cooling that cannot be solved well, affect the health of operators, processing sites and environmental pollution, etc., and achieve remarkable environmental protection , extreme pressure and anti-wear properties/good, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 182.17g (1mol) of sorbitol, 1129.84g (2mol) of dimer acid, and 600g (3mol) of PEG200 into the reaction kettle, stir and heat to 180°C, fully react for 12 hours, and drain the water under reduced pressure, which is a A lubricant composition.

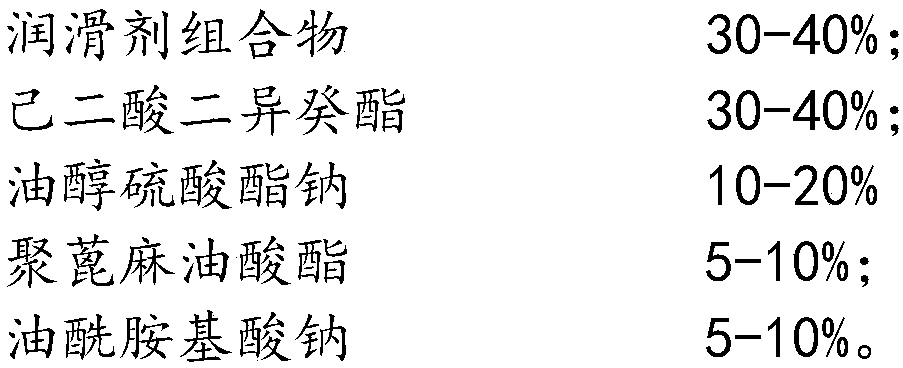

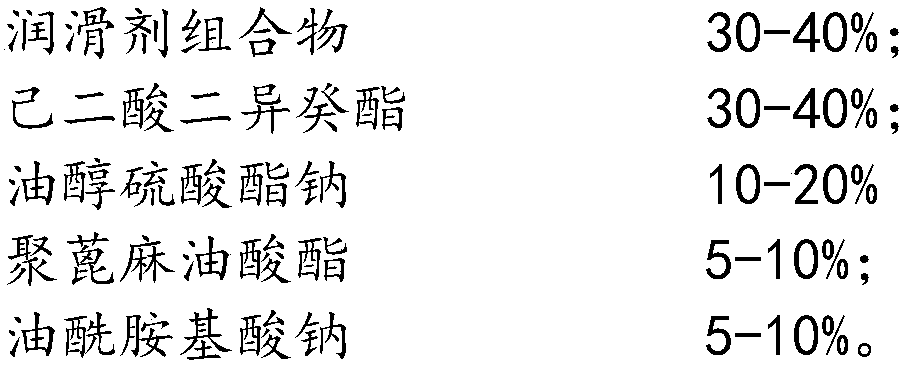

[0032] Weigh 400g of the above-mentioned lubricant composition, 300g of diisodecyl adipate, 200g of sodium oleyl sulfate, 50g of tetrameric ricinoleic acid ester, and 50g of sodium oleyl amidoate, mix and stir at 60°C until it becomes transparent. It is an environmentally friendly micro-cutting fluid.

[0033] The above-mentioned environmentally friendly micro-cutting fluid was tested by the four-ball extreme pressure test method of GB / T12583, and the test result: P D >4903N.

Embodiment 2

[0035] Weigh 182.17g (1mol) of sorbitol, 1694.76g (3mol) of dimer acid, 600g (2mol) of PEG300, and 25g of phosphoric acid (effective component 50%) into the reaction kettle, stir and heat to 240°C, and fully react for 6 Hours, the water is decompressed and discharged, which is a lubricant composition.

[0036] Weigh 300g of the above-mentioned lubricant composition, 400g of diisodecyl adipate, 100g of sodium oleyl sulfate, 100g of hexameric ricinoleic acid ester, and 100g of sodium oleyl amidoate, mix and stir at 40°C until transparent. It is an environmentally friendly micro-cutting fluid.

Embodiment 3

[0038] Weigh 182.17g (1mol) of sorbitol, 1412.3g (2.5mol) of dimer acid, and 480g (1.2mol) of PEG400 into the reaction kettle, stir and heat to 230°C, fully react for 8 hours, and drain the water under reduced pressure, that is as a lubricant composition.

[0039] Weigh 350g of the above lubricant composition, 350g of diisodecyl adipate, 150g of sodium oleyl sulfate, 80g of polyricinoleic acid ester, and 70g of sodium oleyl amidoate, mix and stir at a temperature of about 50°C until it becomes transparent. It is an environmentally friendly micro-cutting fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com