Preparation method of cold-rolled non-oriented silicon steel

A technology of oriented silicon steel and content, which is applied in the field of preparation of non-oriented silicon steel, can solve the problems such as difficulty in magnetic induction, and achieve the effect of improving magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0043] A method for preparing cold-rolled non-oriented silicon steel, comprising the steps of:

[0044] 1) Smelting and continuous casting into slabs

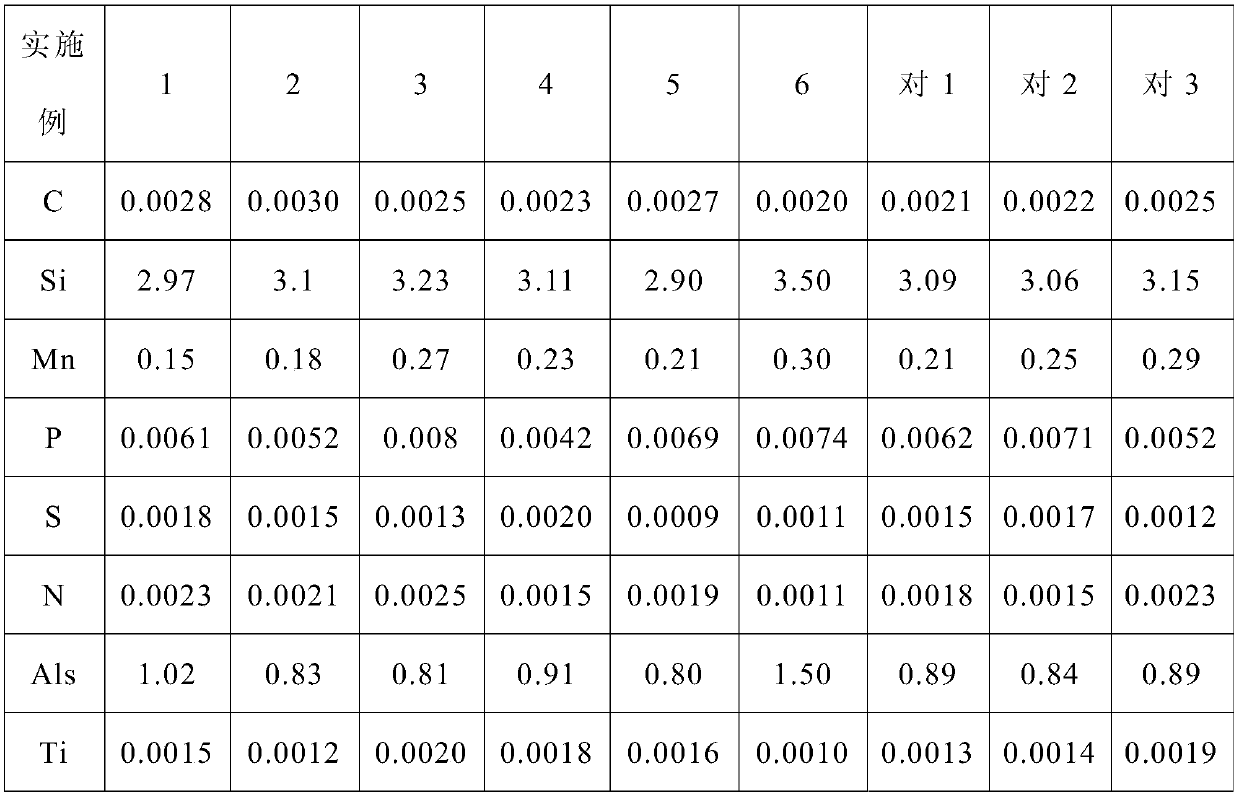

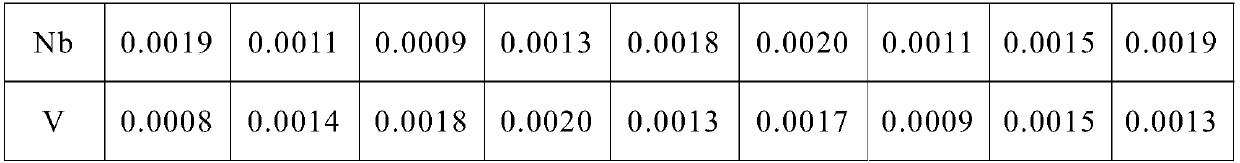

[0045] The composition and weight percentage of cold-rolled non-oriented silicon steel are: C≤0.0030%, Si: 2.90%-3.50%, Mn: 0.15%-0.30%, Als: 0.80%-1.5%, P≤0.008%, S≤ 0.0020%, N≤0.0025%, Ti≤0.0020%, Nb≤0.0020%, V≤0.0020%, the rest are Fe and other unavoidable residual elements;

[0046] 2) Billet heating

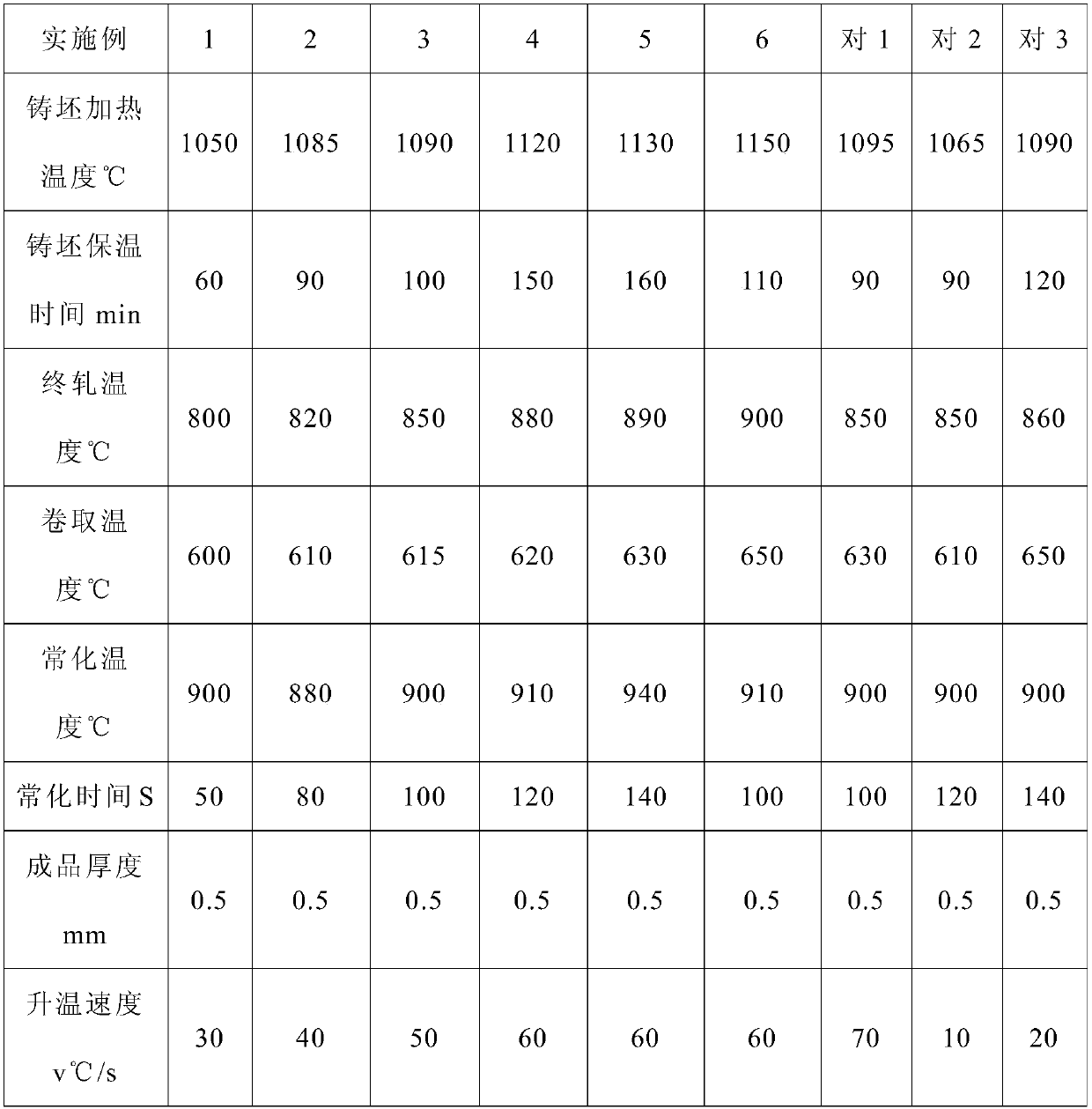

[0047] Heating the billet to 1050-1150°C, holding time for 60-180 minutes;

[0048] 3) hot rolling

[0049] Control the finish rolling temperature at 800-900°C;

[0050] 4) coiling

[0051] Control the coiling temperature to ≥600°C, and the coiled steel coil enters the heat preservation pit and cools down slowly;

[0052] 5) Normalization

[0053] The normalization temperature is 880-940°C, the normalization time is 50-140 seconds, and then the steel strip is subjected to conventional pickling;

[0054] 6) cold rollin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com