A monitorable heat exchanger core for improving heat exchange efficiency

A technology for heat exchange efficiency and heat exchangers, which is applied in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., and can solve problems such as inability to monitor internal operating conditions, low heat exchange efficiency, and inability to perform multiple heat exchanges , to achieve the effect of improving cooling efficiency and use efficiency, improving heat exchange efficiency and maintaining stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

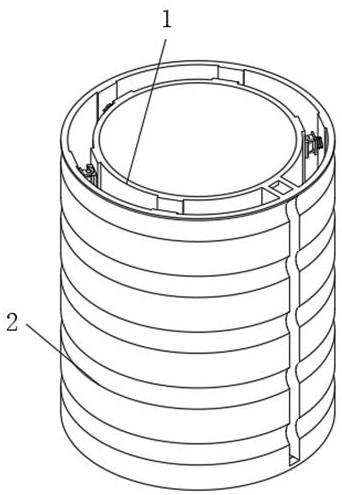

[0038]A monitorable heat exchanger inner core for improving heat exchange efficiency, including an internal protective shell 1;

[0039]Cooling liquid mechanism, the cooling liquid mechanism is arranged inside the inner protective shell 1, and the cooling liquid mechanism is used for compressed air heat exchange;

[0040]The first heat exchange mechanism, the first heat exchange mechanism is arranged inside the inner protective shell 1, and the first heat exchange mechanism is used for primary heat exchange of compressed air;

[0041]The second heat exchange mechanism, the second heat exchange mechanism is arranged inside the inner protective shell 1, and the second heat exchange mechanism is used for the secondary heat exchange of compressed air;

[0042]Monitoring organization, the monitoring organization is arranged inside the internal protective housing 1, and the monitoring organization is used to monitor the heat exchange process;

[0043]The lateral stress relief mechanism is provided with ...

Embodiment 2

[0045]Embodiment 2: The difference based on embodiment 1 is;

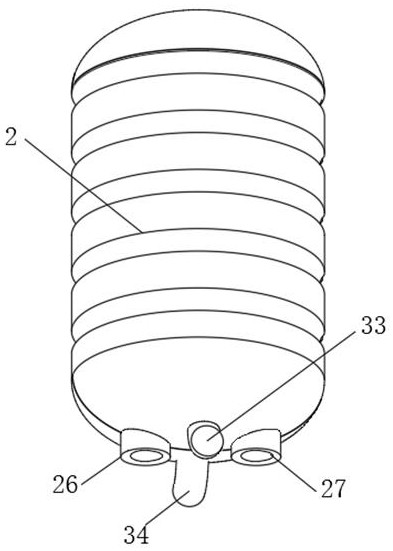

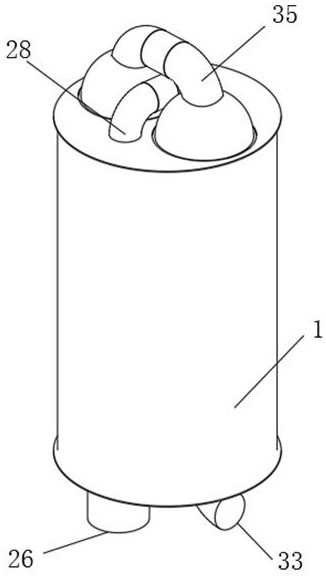

[0046]The coolant mechanism includes: a heat exchange partition 23, a left coolant area 24, a right coolant area 25, a coolant feed pipe 26, a coolant discharge pipe 27, and a coolant connection pipe 28. The inner protective shell 1 passes through an arc The heat exchange baffle 23 is divided into a left cooling liquid area 24 and a right cooling liquid area 25. The upper end of the left cooling liquid area 24 is fixedly connected to the cooling liquid feed pipe 26, and the upper end of the right cooling liquid area 25 is fixed to the cooling liquid discharge pipe 27. The lower end of the left cooling liquid area 24 is connected to the right cooling liquid area 25 through the cooling liquid connecting pipe 28, the left cooling liquid area 24 is fixedly installed with a first heat exchange mechanism, and the right cooling liquid area 25 is fixedly installed with a second heat exchange mechanism. For the thermal mechanism, a ...

Embodiment 3

[0050]Embodiment 3: The difference based on Embodiment 1 and 2 is;

[0051]The first heat exchange mechanism includes: a first heat exchange shell 22, a heat exchange gas inlet pipe 34, and a heat exchange gas connection pipe 35. The first heat exchange shell 22 is movably sleeved in the left cooling liquid zone 24, and the first heat exchange shell 22 An inlet heat exchange mechanism is fixedly installed at the bottom end of the inner wall, a plurality of fluctuating heat exchange mechanisms are fixedly installed on the inner wall of the first heat exchange shell 22 from bottom to top, and the lower end of the first heat exchange shell 22 is fixed with the heat exchange gas inlet pipe 34 The outlet of the upper end of the first heat exchange shell 22 is fixedly connected with the inlet of the heat exchange gas connecting pipe 35, and the outlet of the heat exchange gas connecting pipe 35 is fixedly connected with the second heat exchange mechanism.

[0052]The imported heat exchange mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com