Automatic large-size workpiece measurement system based on machine vision

An automatic measurement and machine vision technology, applied in the field of visual measurement, can solve problems such as low efficiency and large errors, and achieve the effect of removing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

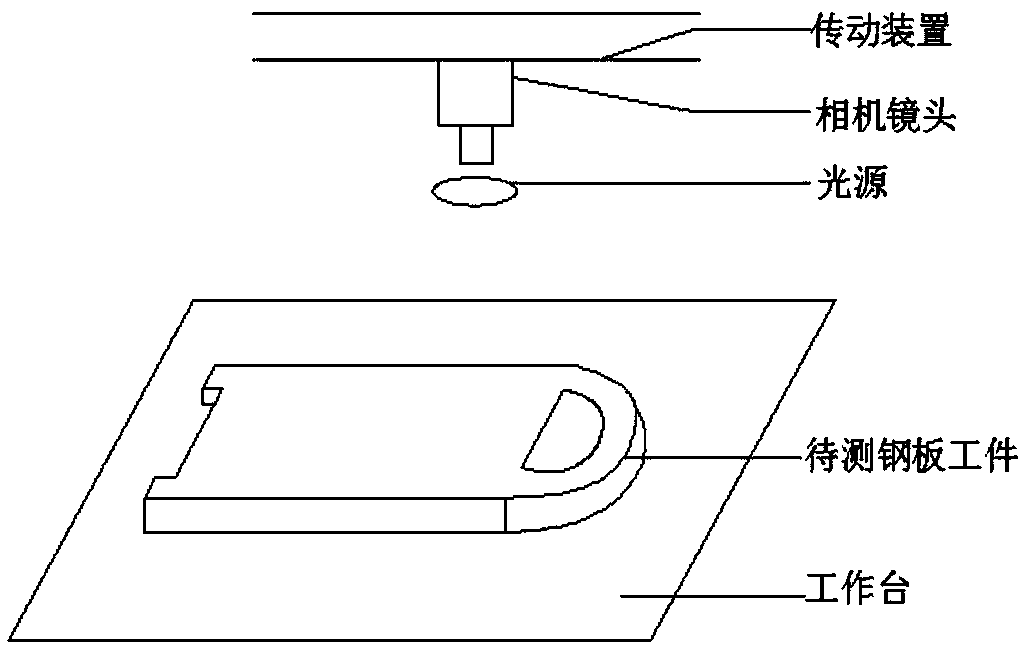

[0075] A kind of automatic measurement system of large-size workpiece based on machine vision of the present invention, such as figure 1 As shown, including the table, the steel plate workpiece to be tested, the transmission device, the camera lens and the light source.

[0076] The camera lens is set under the transmission device, the light source is set under the camera lens, the steel plate workpiece to be tested is placed on the workbench, and the workbench is placed under the light source.

[0077] The light source can generally be set as a backlight light source and a forward light source; the back light source can usually obtain higher contrast, and the forward light source can obtain the surface information of the workpiece to be measured; the light source in this embodiment is set as a forward light source. However, in the process of image acquisition, if there is no suitable light source, the captured image will have different brightness and darkness, which will brin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com