Photonic crystal damping material plate

A technology of phononic crystals and damping materials, which is applied in the direction of lamination devices, laminations, and layered products, etc., can solve the problems of phononic crystals controlling low frequencies, achieve convenient use, reduce the risk of first-order resonance, and improve comfort. and safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

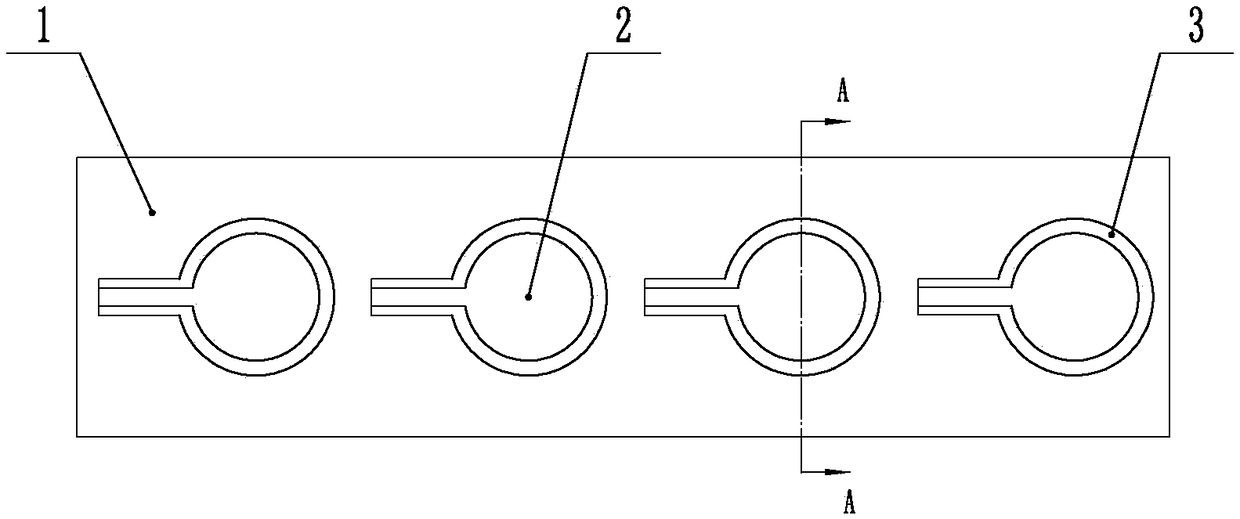

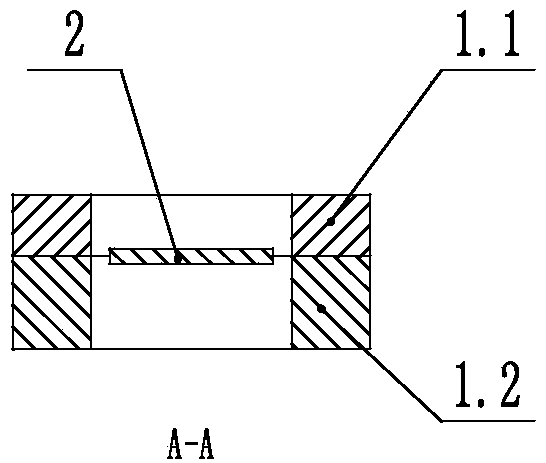

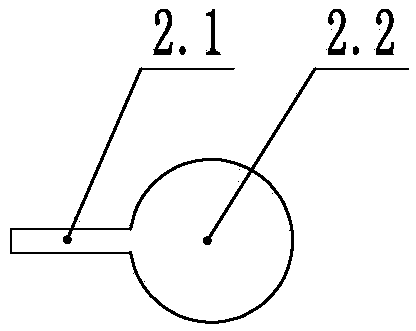

[0037] Assuming that a 0.5mm thick aluminum sheet is selected to manufacture the phononic crystal structure layer, the mass unit is circular with a diameter of 35mm; when the length of the elastic unit is 15mm and the width is 5mm, the hole diameter is 45mm, and the phononic crystal structure layer unit is arranged in 4 holes with a distance of 20mm and magnetic The thickness of the damping layer is 1.5mm, and the thickness of the hot-melt damping layer is 1mm. In this state, the equivalent mass of the phononic crystal structure layer is 1.41g, the equivalent stiffness of the phononic crystal structure layer is 112233.47N / m, and the band gap frequency is 45Hz.

Embodiment 2

[0039] In the overall design state of Example 1, by adding 0.9g of aluminum sheet (thickness 0.5mm) to the mass unit, the equivalent mass is 2.31g, the equivalent stiffness is 112233.47N / m, and the forbidden band frequency is 35Hz .

Embodiment 3

[0041] In the overall design state of Example 1, by adding 1.1g of aluminum sheet (thickness 0.5mm) to the mass unit, the equivalent mass is 2.51g, the equivalent stiffness is 112233.47N / m, and the bandgap frequency is 34Hz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com