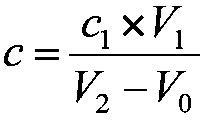

Method for measuring iron/calcium ratio in iron-calcium core-spun yarn

A determination method and a core-coated wire technology, applied in the field of chemical analysis, can solve the problems of difficult observation of the EDTA titration end point, many calcium particles in the reduced iron powder, complicated operation steps, etc., to achieve stable complexes, simple drugs, and separation good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] The comparison between the method of the present invention and the prior art is listed in Table 1 below.

[0099] Table 1: Comparison results between the method of the present invention and the method disclosed in patent CN103115920A

[0100]

Embodiment 2

[0102] Table 2 below lists the measurement results of the iron-calcium ratio in the iron-calcium cored wire using the method of the present invention and the method disclosed in the prior art.

[0103] Table 2: The method of the present invention and the disclosed method of patent CN103115920A are to the measurement result of iron-calcium ratio in iron-calcium cored wire

[0104]

[0105]

[0106] It can be seen from the above table 2 that the data obtained by using this method to measure Fe: Ca in the iron-calcium cored wire sample are accurate and reliable.

[0107] From the comparative results of the above example 1 and example 2, it can be known that the method of the present invention can accurately measure the content of Fe:Ca in the iron-calcium cored wire sample. In addition, the method is simple, fast, and easy to master, requires simple equipment and medicines, low measurement cost, low pollution, and high detection efficiency, which can meet the needs of rapid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com