Silicon heterojunction solar cell and preparation method thereof

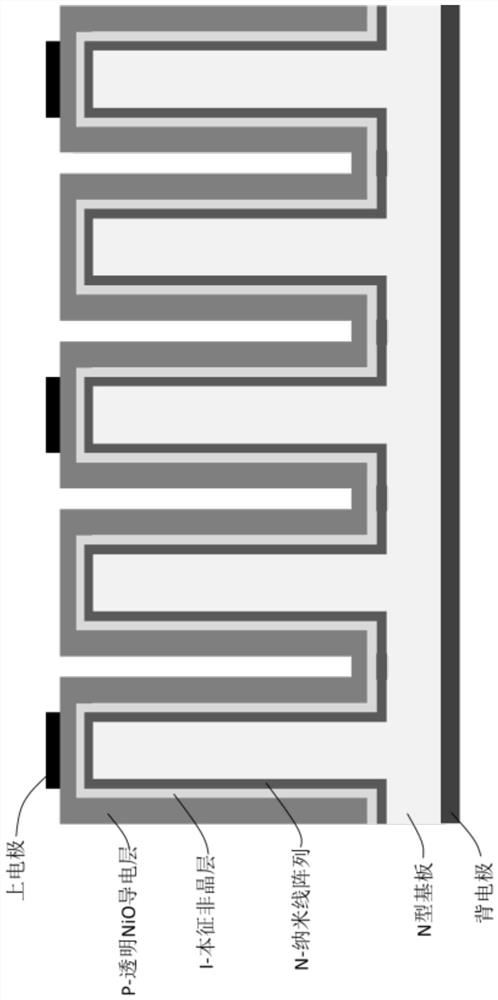

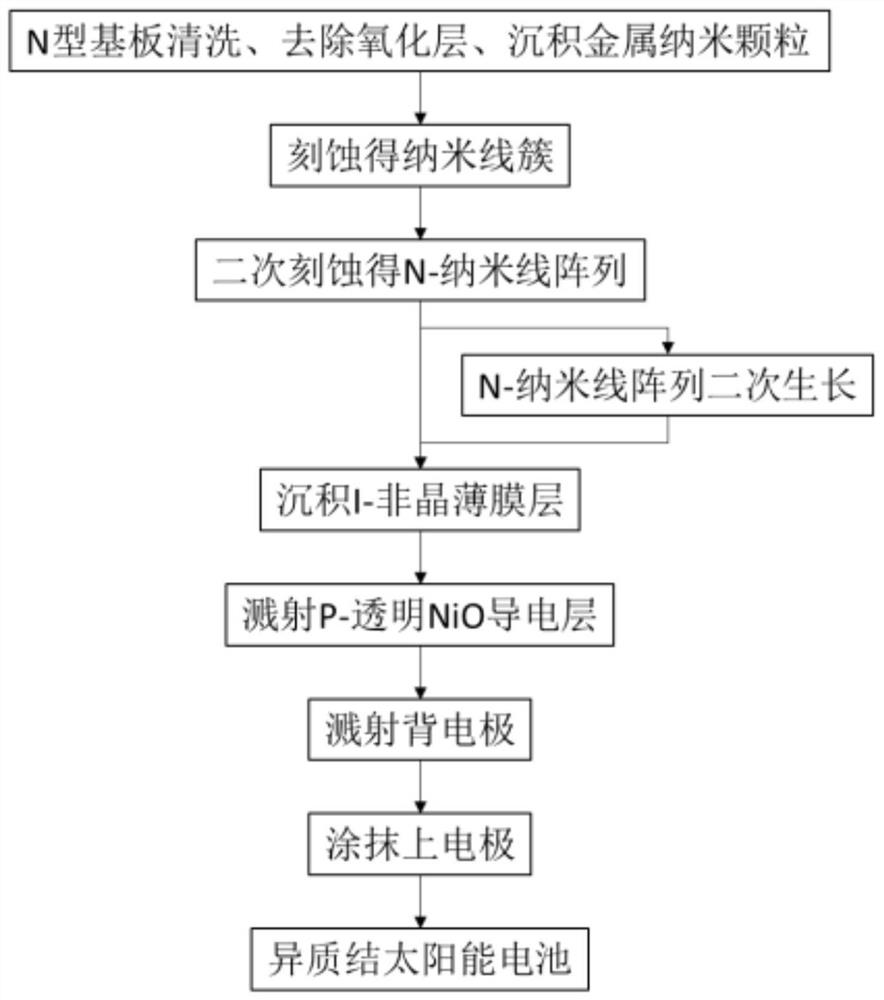

A solar cell, silicon heterojunction technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problem of attenuation of cell performance, increased surface area of nanowire arrays, surface recombination, and limited ability of short nanowires to absorb sunlight, etc. problems to ensure performance and avoid losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The back electrode has a thickness of 200nm and is made of metal aluminum;

[0046] N-type substrate, the thickness of which is 200 μm, the material is single crystal silicon, and nano-silver particles are deposited on the surface;

[0047] A nanowire cluster, the length of which is 1.8 μm, and the bottom diameter of each nanowire in the nanowire cluster is 190 nm;

[0048]Using potassium hydroxide with a concentration of 10wt% and a pH of 15 to etch a second time for 10s, an N-nanowire array is obtained, wherein the length of each nanowire is 1 μm, and the diameter of the lower end surface is 190nm , The upper end is in the shape of a spherical crown, the diameter of the spherical bottom surface is 170nm, and the distance between adjacent nanowires is 100nm (between the lower end surface or the root);

[0049] I-intrinsic amorphous layer, its thickness is 70nm, material is germanium thin film;

[0050] P-transparent NiO conductive layer, its thickness is 140nm;

[0...

Embodiment 2

[0053] The back electrode has a thickness of 300nm and is made of metallic silver;

[0054] N-type substrate with a thickness of 300 μm, made of single crystal silicon, and deposited with nano-aluminum particles on the surface;

[0055] A nanowire cluster, the length of which is 2.0 μm, and the bottom diameter of each nanowire in the nanowire cluster is 205 nm;

[0056] N-nanowire arrays were obtained after secondary etching with sodium hydroxide with a concentration of 10wt% and a pH of 15 for 15 seconds, wherein the length of each nanowire was 1 μm, and the diameter of the lower end surface was 200 nm. , The upper end is in the shape of a spherical crown, the diameter of the spherical bottom surface is 170nm, and the distance between adjacent nanowires is 110nm (between the lower end surface or the root);

[0057] I-intrinsic amorphous layer, its thickness is 90nm, material is silicon thin film;

[0058] P-transparent NiO conductive layer, its thickness is 150nm;

[0059]...

Embodiment 3

[0061] The back electrode has a thickness of 200nm and is made of metal aluminum;

[0062] N-type substrate with a thickness of 200 μm, made of single crystal silicon, and deposited with nano-silver particles on the surface;

[0063] A nanowire cluster, the length of which is 1.8 μm, and the bottom diameter of each nanowire in the nanowire cluster is 190 nm;

[0064] After 15 seconds of secondary etching with potassium hydroxide with a concentration of 10wt% and a pH of 15, N-nanowire arrays were obtained by continuing PECVD regrowth, wherein the length of each nanowire was 1.2 μm, and the diameter of the lower end surface was 190 nm. , The upper end is in the shape of a spherical crown, the diameter of the spherical bottom surface is 110nm, and the distance between adjacent nanowires is 100nm (between the lower end surface or the root);

[0065] I-intrinsic amorphous layer, its thickness is 80nm, and material is germanium thin film;

[0066] P-transparent NiO conductive lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com