Paper tube type mulch two-stage cleaning and recycling machine

A recycling machine and mulch technology, applied in plant protection covers, botany equipment and methods, horticulture, etc., can solve the problems of destroying soil air permeability, destroying soil physical properties, and non-reusable mulching films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

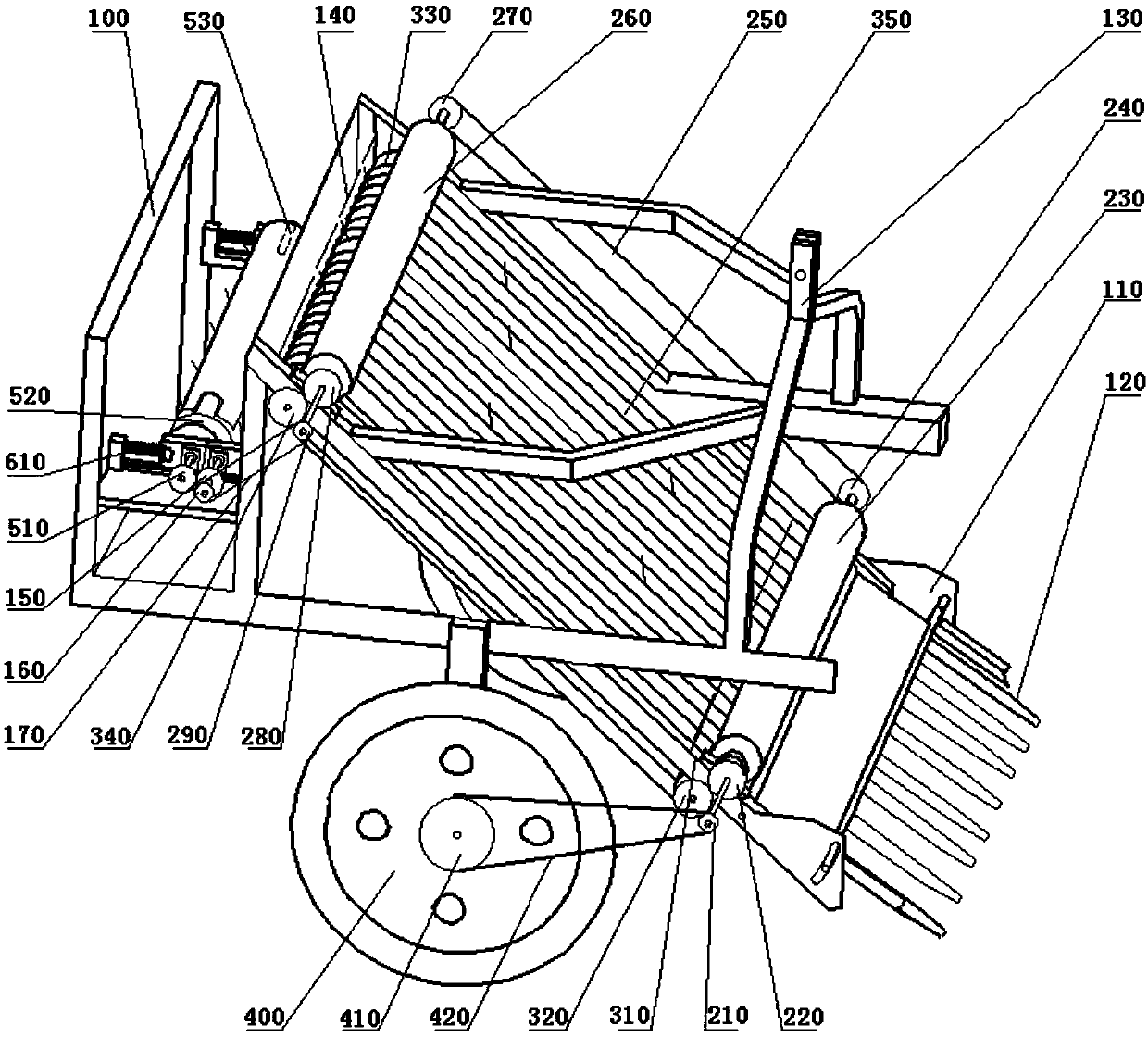

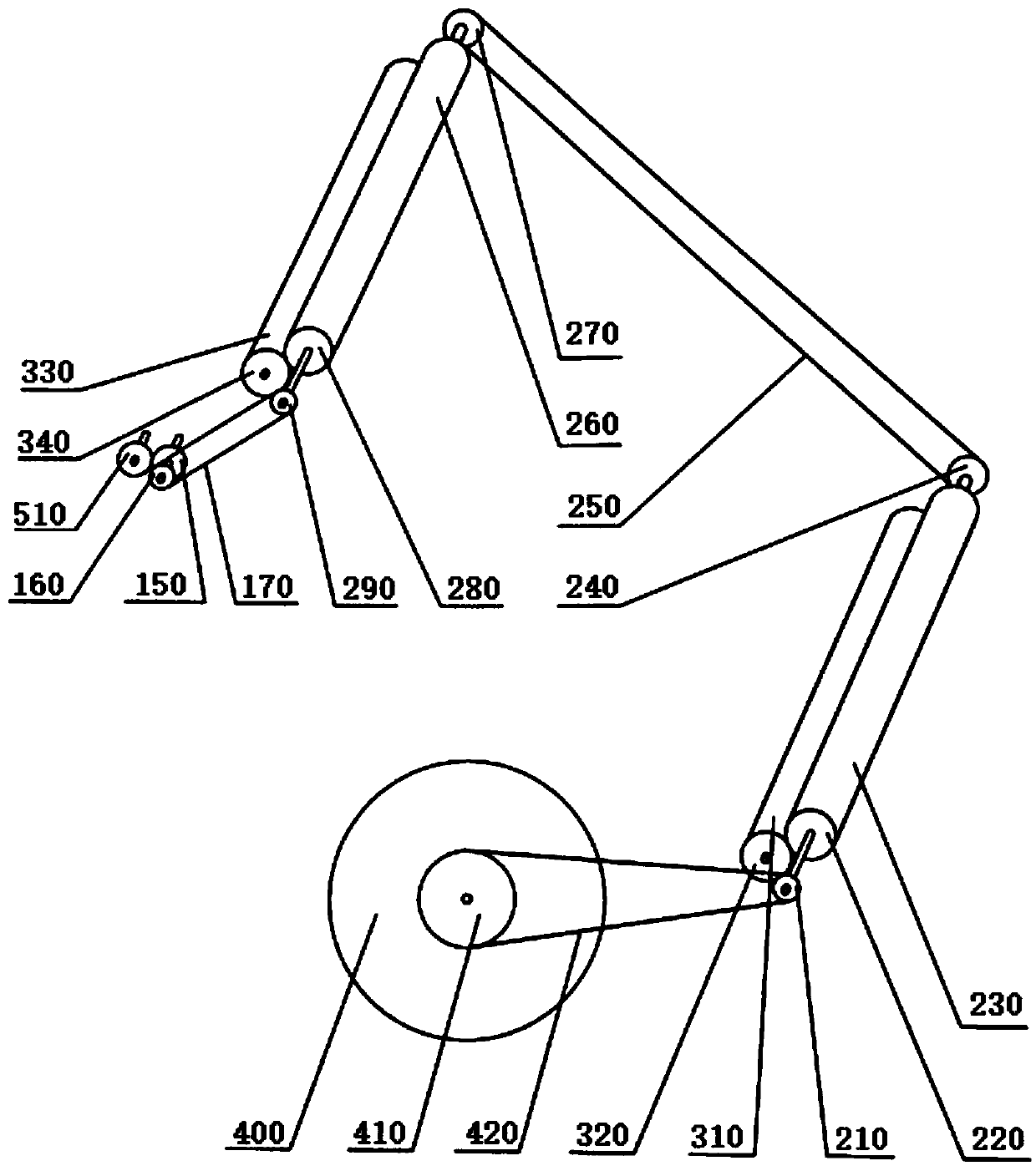

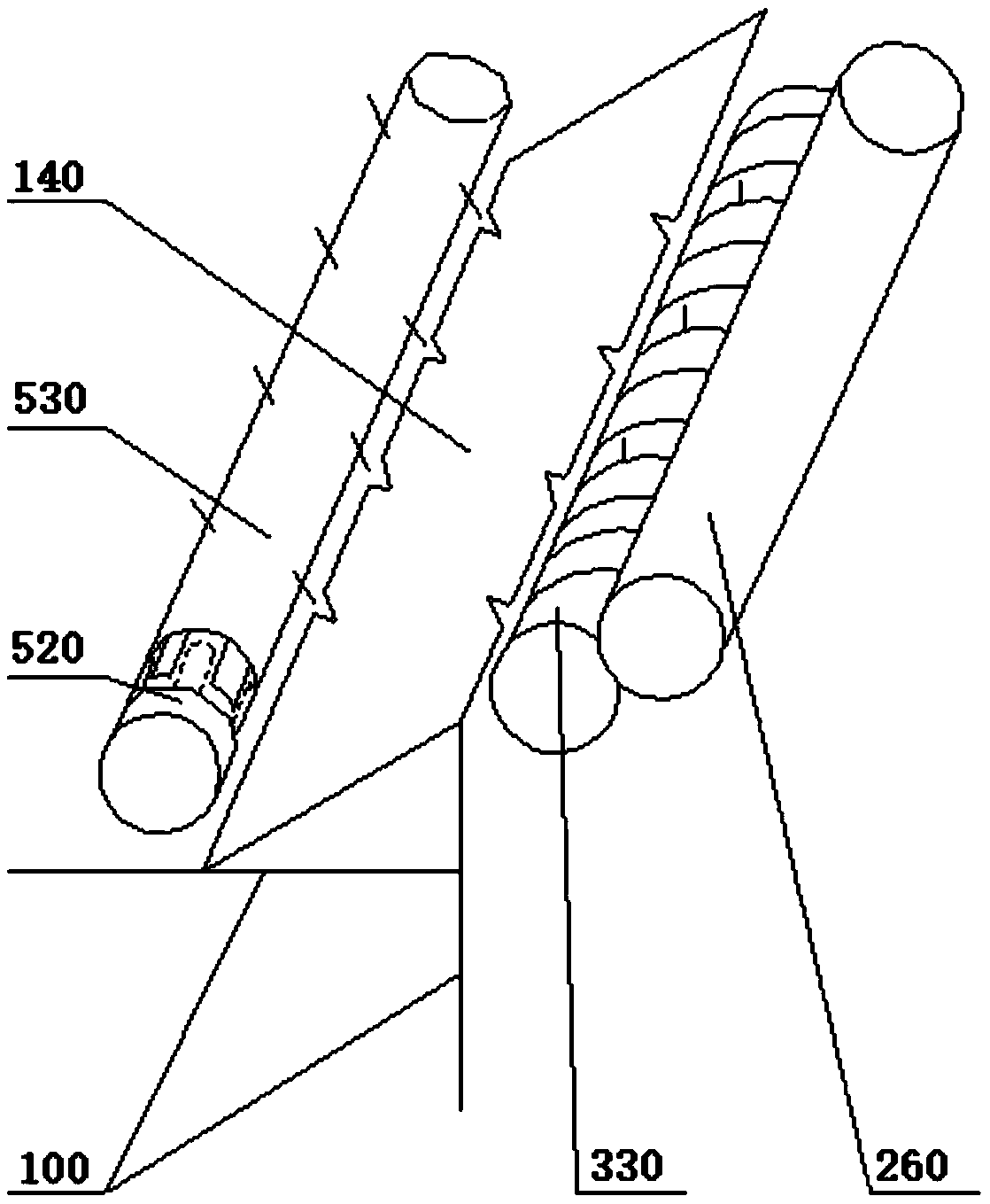

[0057] Such as figure 1 , 2 As shown, the present invention provides a two-stage cleaning and recycling machine for paper tube mulch film, including: frame 100, angle adjuster 110, film removal teeth 120, suspension frame 130, ground wheel 400, main roller mechanism, auxiliary roller mechanism, conveying The toothed belt 350, the second transmission sprocket mechanism and the anti-breaking film device.

[0058] The frame 100 includes a frame body and a support frame. The frame body is arranged obliquely and has a quadrilateral structure. The support frames are fixed on both sides of the frame body. A first longitudinal beam and a second longitudinal beam arranged perpendicular to it, wherein the first longitudinal beam is arranged at one end of the first longitudinal beam, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com