Preparation method of potato chip type reprocessed cheese and product thereof

A technology for processed cheese and potato chips is applied in the field of preparation of potato chip type processed cheese to achieve the effect of suitable brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

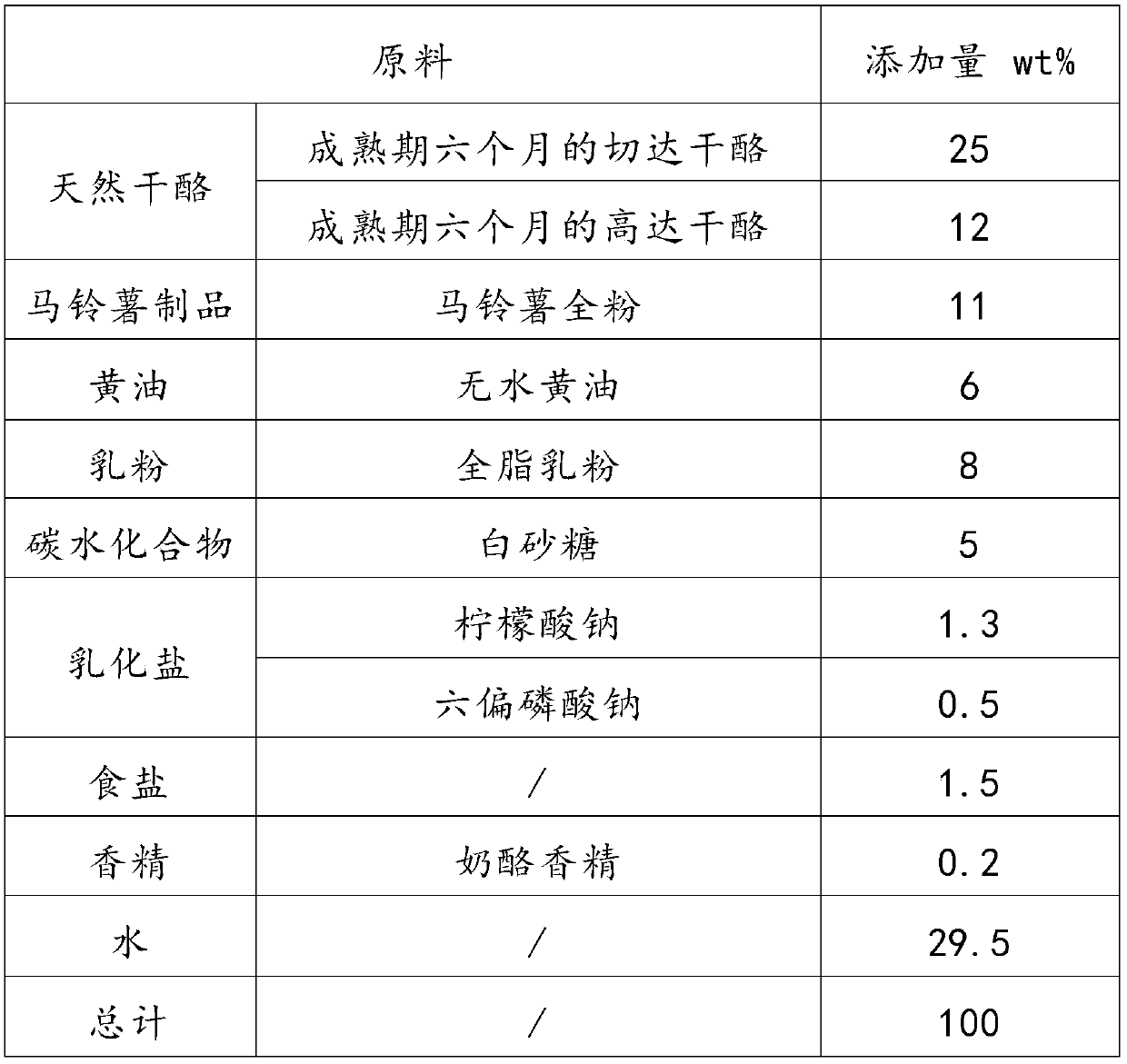

[0033] 1. Raw material formula:

[0034]

[0035] 2. Preparation method:

[0036] (1) Mix natural cheese, butter, carbohydrates, milk powder, emulsifying salt, table salt, essence and water evenly, heat at 90°C, stir at 1500rpm for 18min, and emulsify to obtain feed liquid A;

[0037] (2) The potato product is added to the material liquid A while stirring, and the dough B is obtained by stirring evenly;

[0038] (3) Dough B is delivered to the rolling mill, and rolled into a dough with a thickness of 2mm;

[0039] (4) sending the roll-rolled dough to a roll-cut forming machine and cutting it into a circle with a diameter of 5 cm;

[0040] (5) Transfer the roll-cut dough to a fully automatic baking line for baking. The upper heat is controlled at 200-220°C, and the lower heat is controlled at 150-170°C for 5 minutes;

[0041] (6) Transfer the baked potato chips to the cooling line, rapidly cool to 26-30° C., remove the fragments, and pack them to obtain the potato chip-ty...

Embodiment 2

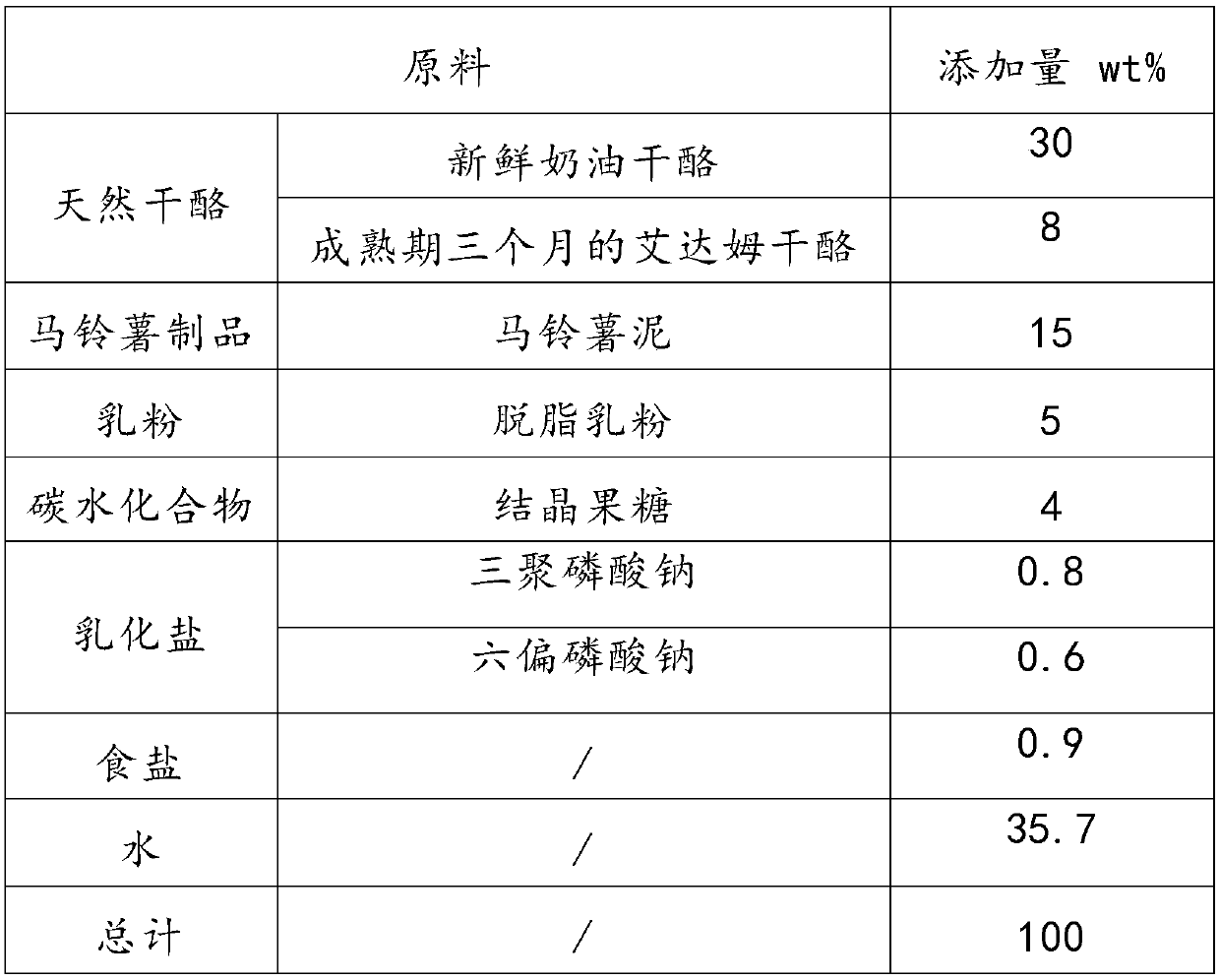

[0043] 1. Raw material formula:

[0044]

[0045] 2. Preparation process:

[0046] (1) Mix natural cheese, milk powder, carbohydrates, emulsifying salt, table salt and water evenly, heat at 95°C, stir at 1200rpm for 25min, and emulsify to obtain feed liquid A;

[0047] (2) The potato product is added to the material liquid A while stirring, and the dough B is obtained by stirring evenly;

[0048] (3) Dough B is delivered to a rolling mill, and rolled into a dough with a thickness of 3mm;

[0049] (4) sending the roll-rolled dough into a roll-cut forming machine and cutting it into a circle with a diameter of 2 cm;

[0050] (5) Transfer the roll-cut dough to a fully automatic baking line for baking, and control the temperature at 180-200°C for heating, and control the temperature at 140-160°C for 6 minutes;

[0051] (6) Transfer the baked potato chips to the cooling line, rapidly cool to 26-30° C., remove the fragments, and pack them to obtain the potato chip-type process...

Embodiment 3

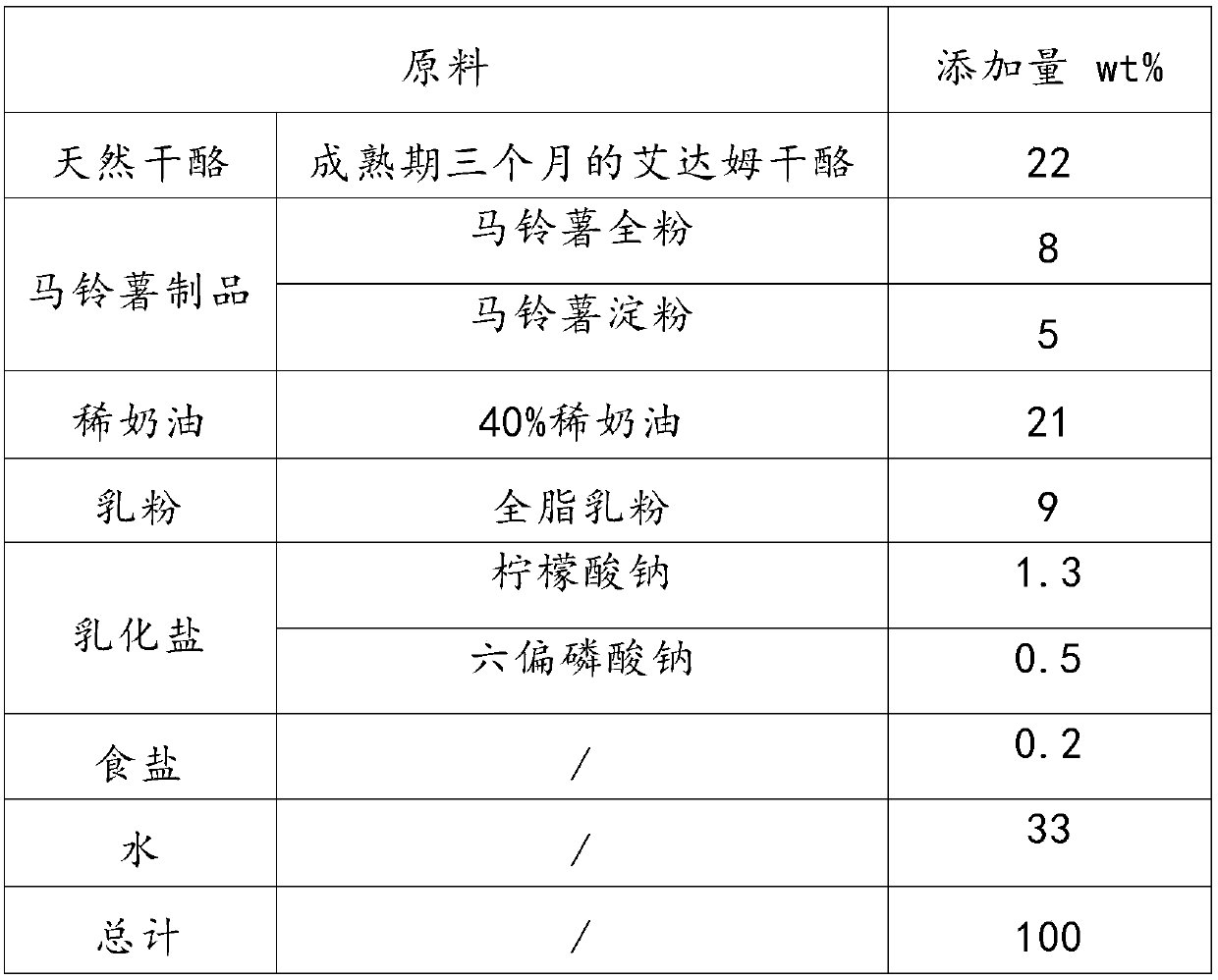

[0053] Raw material formula:

[0054]

[0055] 2. Preparation process:

[0056] (1) Mix natural cheese, cream, milk powder, emulsifying salt, table salt and water evenly, heat at 85°C, stir at 2000rpm for 15min, and emulsify to obtain feed liquid A;

[0057] (2) The potato product is added to the material liquid A while stirring, and the dough B is obtained by stirring evenly;

[0058] (3) Dough B is delivered to a rolling mill, and rolled into a dough with a thickness of 4mm;

[0059] (4) the rolled dough is sent to the roll cutting machine and the roll is cut into a circle with a diameter of 6cm;

[0060] (5) Transfer the roll-cut dough to a fully automatic baking line for baking. The upper heat is controlled at 210-220°C, and the lower heat is controlled at 160-170°C for 5 minutes;

[0061] (6) Transfer the baked potato chips to the cooling line, rapidly cool to 26-30° C., remove the fragments, and pack them to obtain the potato chip-type processed cheese.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com