Filter core for super high voltage transformer charged filtering oil and manufacturing method thereof

A manufacturing method and transformer technology, which are applied in the fields of transformer/inductor cooling, chemical instruments and methods, separation methods, etc., can solve the problems of single index, low efficiency and long working time of oil filtering projects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

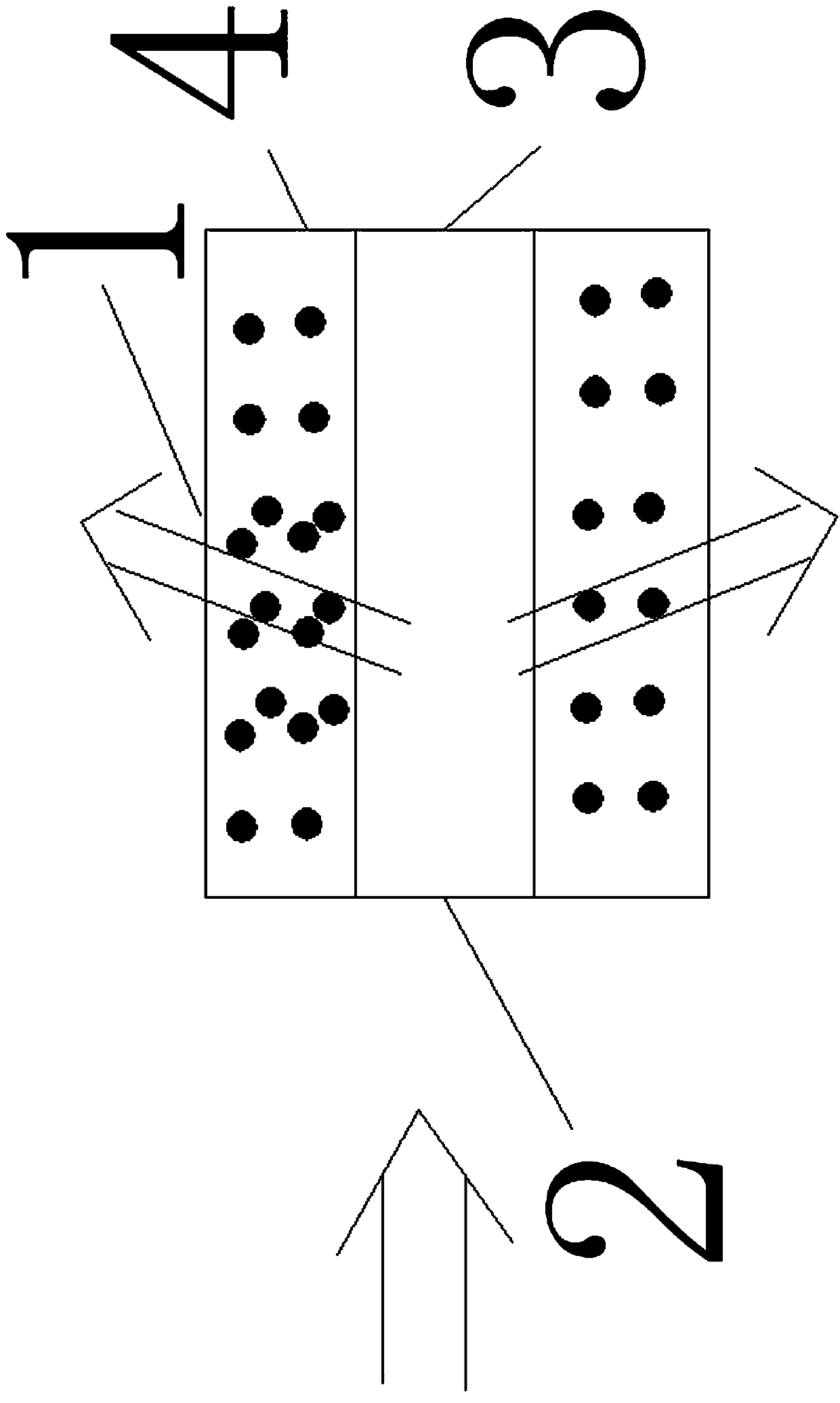

[0023] The filter element 1 is a cylinder, the middle part of the filter element 1 has a through hole in the axial direction, one end is the core body inlet 2, and the other end is the core body outlet 3. There is a sealing plate 4 at the outlet of the core outlet 3 . The oil enters from the inlet 2 of the core body and flows out after being filtered by the filter element 1.

[0024] A filter element used for live oil filtering of ultra-high voltage transformers is mainly made of solidified 4.5 parts of activated clay, 4.5 parts of silica gel and 1 part of adsorbent. The number of parts mentioned is the number of parts by mass.

[0025] The active surface of the activated clay is 100m 2 / g, the active surface of silica gel is 300m 2 / g, the active surface of the adsorbent is 530m 2 / g. The adsorbent model is 801.

[0026] The curing agent is a resin, and the quality of the resin is 8% of the sum of the mass of activated clay, silica gel and adsorbent.

[0027] A method ...

Embodiment 2

[0030] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0031] A filter element for live oil filtering of ultra-high voltage transformers is mainly made of 3.5 parts of activated clay, 6 parts of silica gel and 0.5 parts of adsorbent. The curing agent is a resin, and the quality of the resin is 9% of the sum of the mass of activated clay, silica gel and adsorbent.

[0032] The ingredients of the filter element 1 are used when the oil medium loss value is 1-4% at 90°C.

Embodiment 3

[0034] Embodiment 3 is basically the same as Embodiment 1, and its difference is:

[0035] A filter element used for live oil filtering of ultra-high voltage transformers is mainly made of 9.5 parts of silica gel and 0.5 parts of adsorbent. The curing agent is resin, and the mass of resin is 10% of the sum of silica gel and adsorbent mass.

[0036] The ingredients of the filter element 1 are used when the oil medium loss value is 0.5-1% at 90°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com