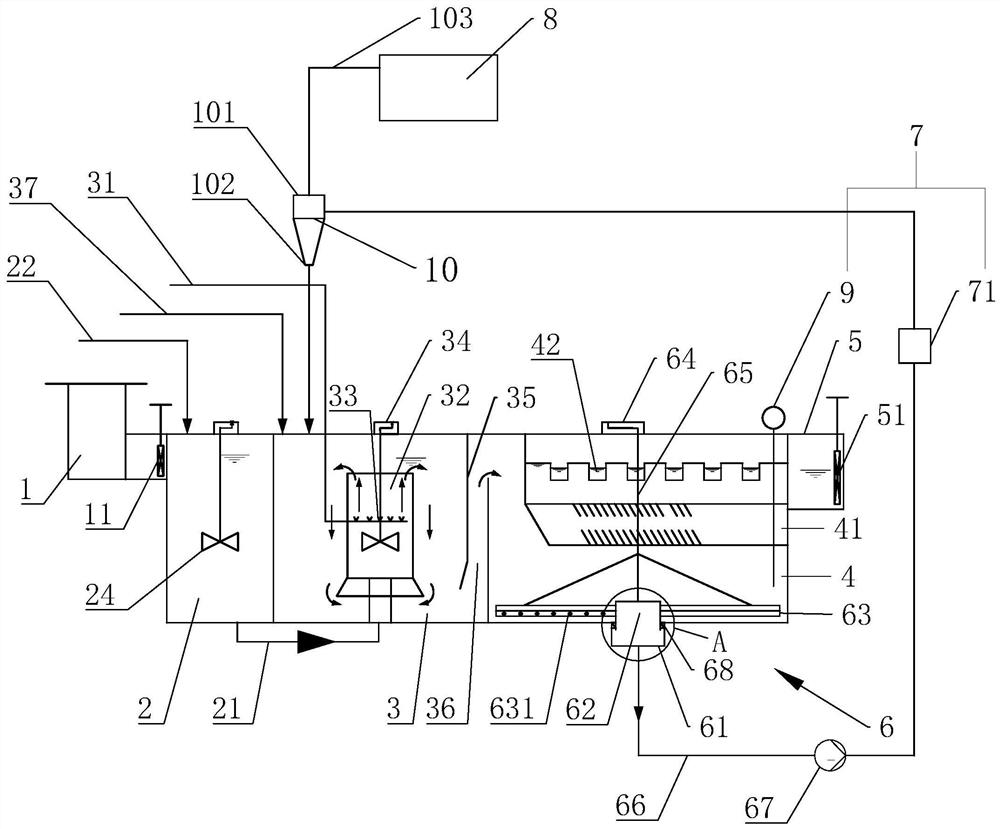

A sand-adding sedimentation tank for realizing efficient sludge discharge

A sedimentation tank, high-efficiency technology, applied in sedimentation separation, sedimentation tank, sediment separation by centrifugal force, etc., can solve the problems of low sludge discharge efficiency, high investment cost, easy torque overload, etc., to improve sludge discharge efficiency and investment cost. Low, reduced usage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0061] Referring to Fig. 6, the difference between the present embodiment and the first embodiment is that a water weir is provided between the coagulation area 2 and the flocculation area 3, and the water weir is a shared room wall of two adjacent areas, and the shared The top of the chamber wall is lower than the tank top level, so that the coagulation zone 2 and the flocculation zone 3 are connected. In the coagulation zone 2, a first baffle 25 is vertically arranged, and the lower end of the first baffle 25 is at the bottom of the coagulation zone 2. Above, a water passage is formed between the lower end of the first baffle plate 25 and the bottom of the coagulation zone 2, through which the sewage from the water distribution well 1 can enter the coagulation zone 2, thereby preventing short flow of sewage.

[0062] Wherein, a coagulant adding pipe 22 for adding coagulant is connected between the second baffle plate and the water inlet gate 11 in the coagulation area 2 . A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com