NID desulfurization process and cloth bag dust removing device for desulfurization process

A bag filter and desulfurization technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of surface blockage of filter bags, sticking bags, easy adhesion of flue gas, etc., and prolong the service life. , delaying speed, enhancing drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

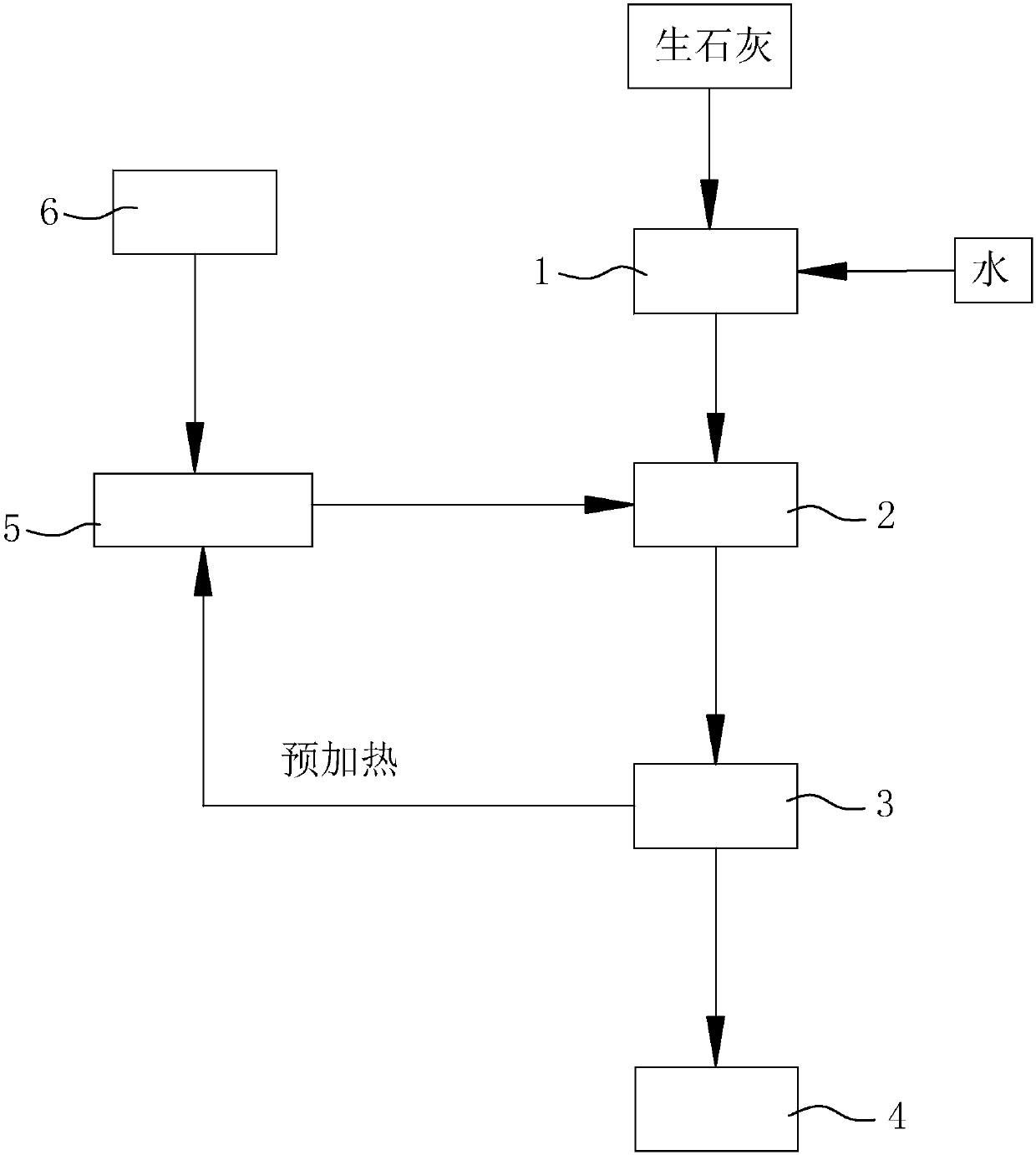

[0044] Embodiment: a kind of NID desulfurization process and the bag filter for this desulfurization process, such as figure 1 As shown, the NID desulfurization process includes the following steps:

[0045] Step 1: Digest quicklime into calcium dioxide by adding water in digester 1;

[0046] Step 2: Mix the calcium dioxide in the digester 1 and the dust collected in the bag filter 5 in the mixer 2, add water and humidify to form mixed ash;

[0047] The third step: the humidified mixed ash is desulfurized with the flue gas in the boiler 6 in the reactor 3;

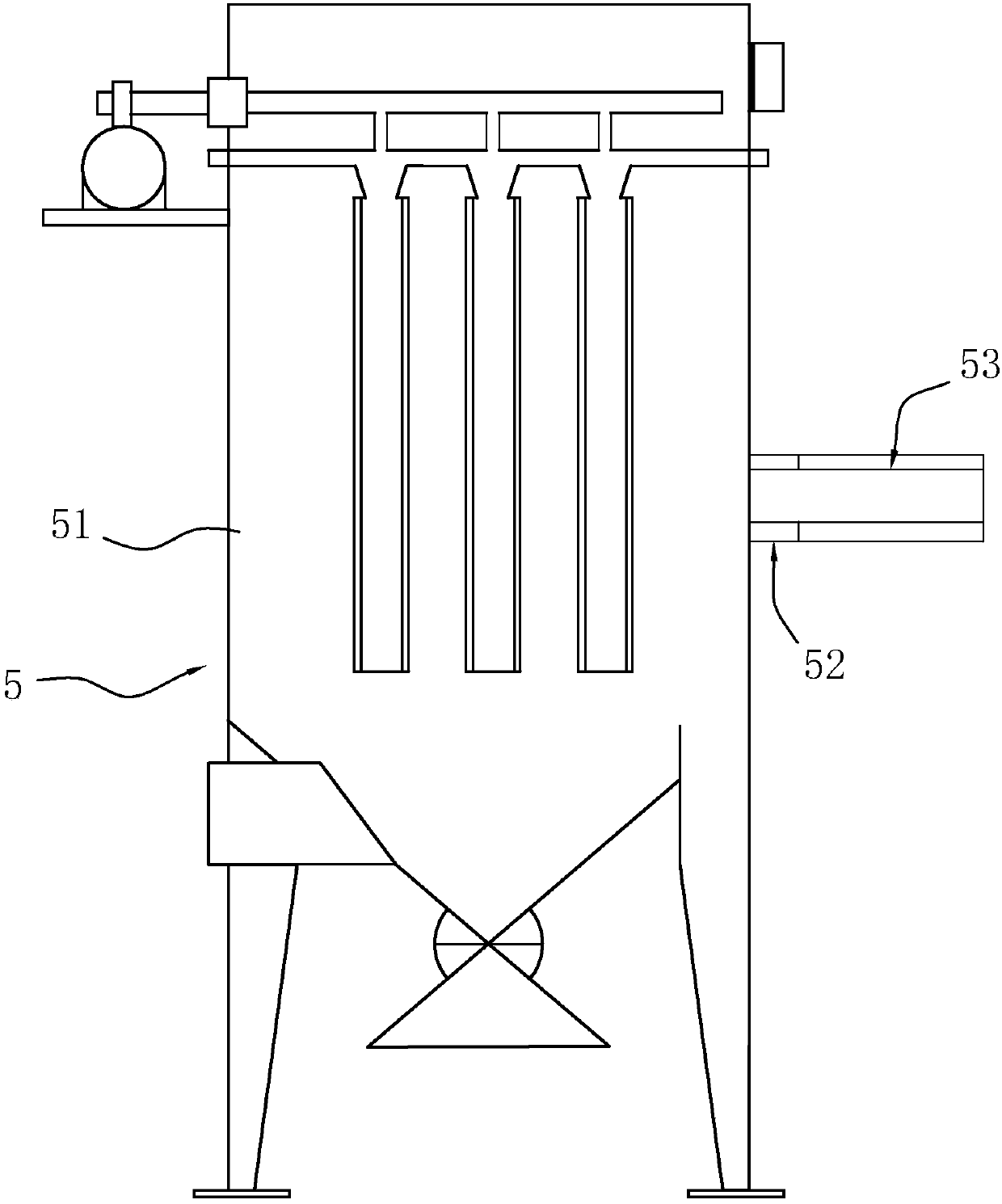

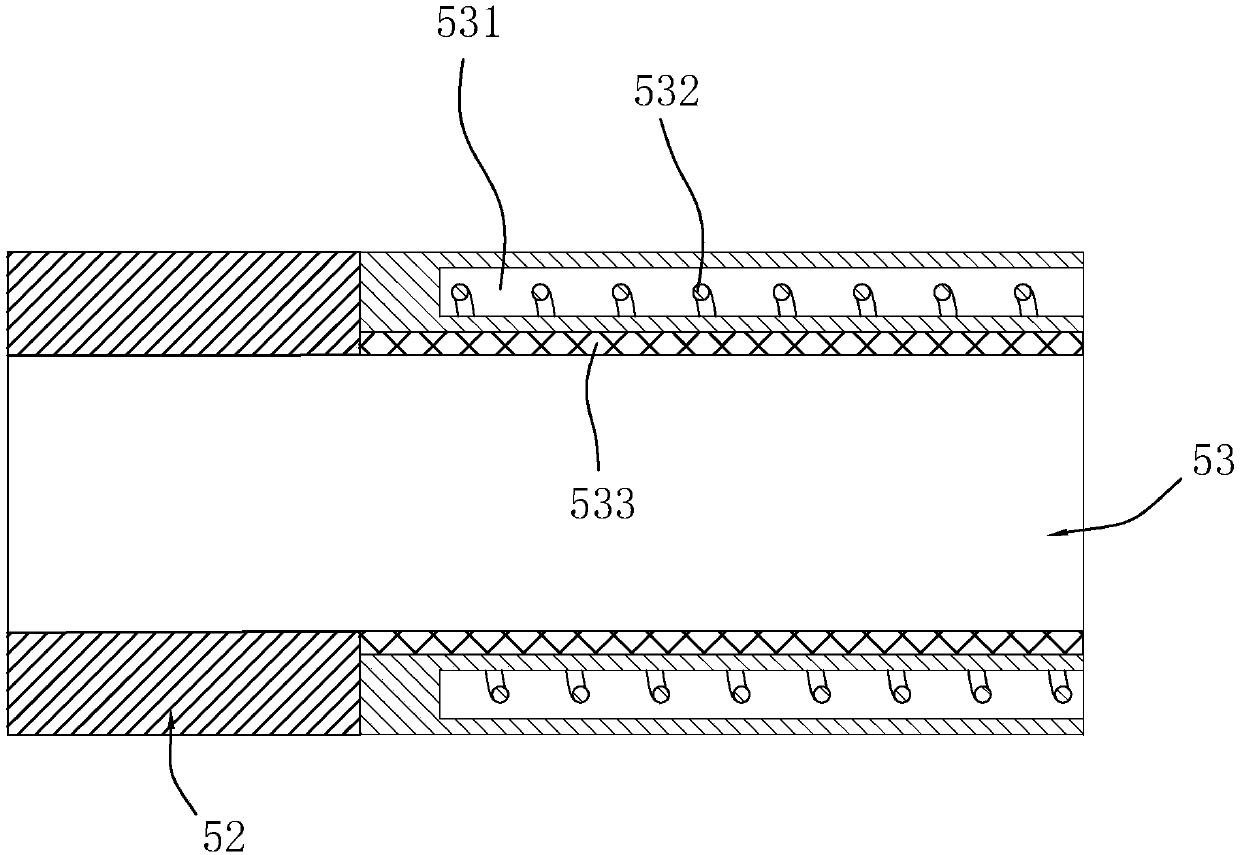

[0048] Step 4: The flue gas after the desulfurization reaction in the mixer 2 is returned to the bag filter 5 for circulation and cleaning, and the second and third steps are repeated; the flue gas is preheated before entering the flue gas inlet 52 of the bag filter 5 Treatment, specifically, the flue gas is preheated at the flue gas inlet 52 of the bag filter 5;

[0049] Step 5: The flue gas in the mixer 2 is transport...

Embodiment 2

[0052] Embodiment 2: a kind of NID desulfurization process and the bag filter used for this desulfurization process, differ from embodiment 1 in that, as Figure 4 As shown, a guide pipe 54 is fixedly connected between the preheating passage 53 and the flue gas inlet 52 , and the diameter of the guide pipe 54 gradually decreases toward the flue gas inlet 52 . The guide pipe 54 gradually reduces the flow area before the flue gas enters the flue gas inlet 52, and delays the time for the flue gas to enter the bag filter 5, so that the flue gas can stay in the preheating channel 53 for a longer time and be preheated. The heating of the channel 53 increases the drying time and enhances the drying effect.

Embodiment 3

[0053] Embodiment 3: a kind of NID desulfurization process and the bag filter used for this desulfurization process, differ from embodiment 2 in that, as Figure 5 As shown, the guide tube 54 can also be fixed in the preheating channel 53, thereby reducing the length of the entire structure and reducing the occupied space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com