Sieve plate preventing material adhesion and vibrating screen with same

A vibrating screen and material technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of large vibration amplitude of the screen surface, large space occupation, large screen surface angle, etc., to avoid adhesion, good elasticity, and reduce material stickiness attached effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

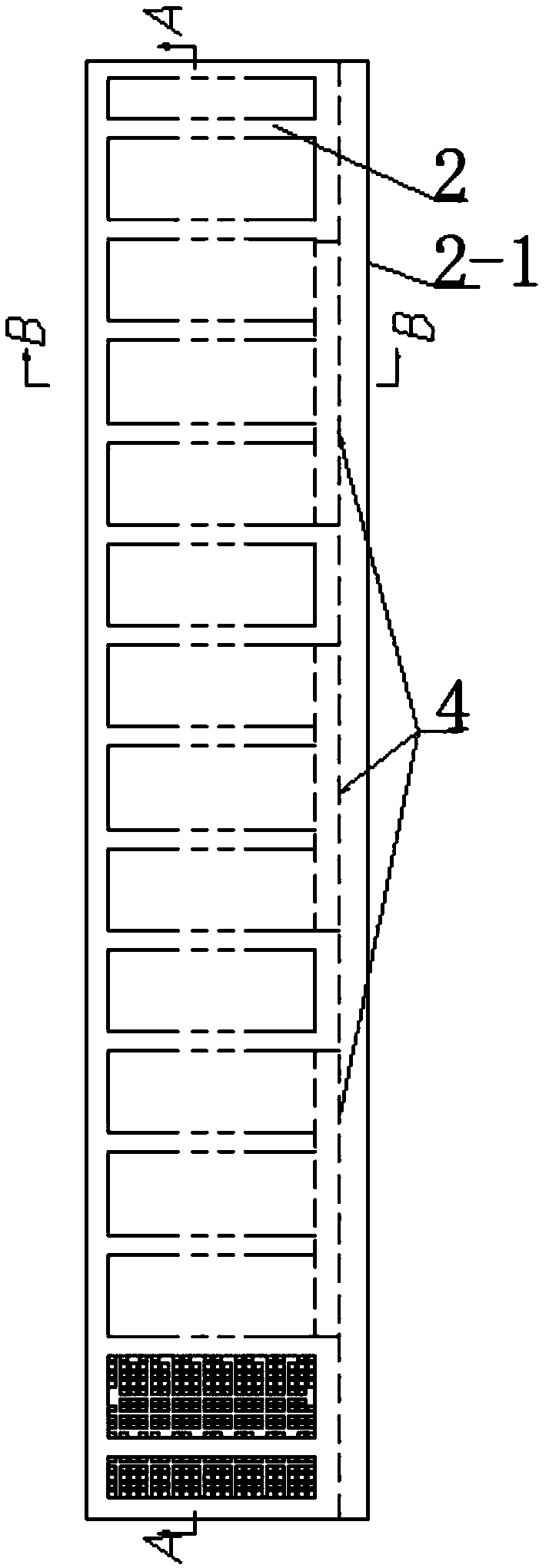

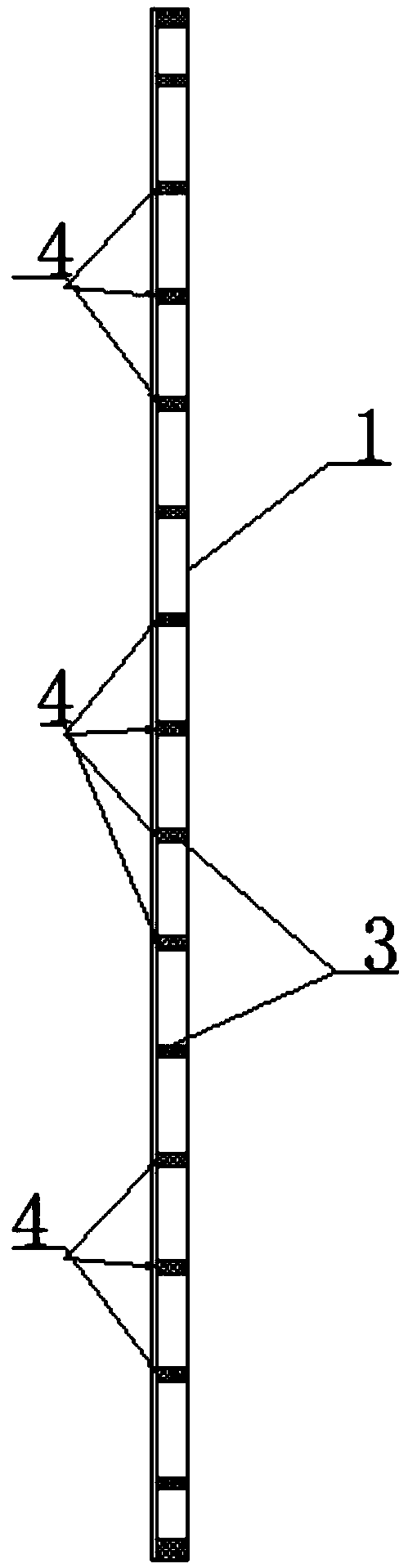

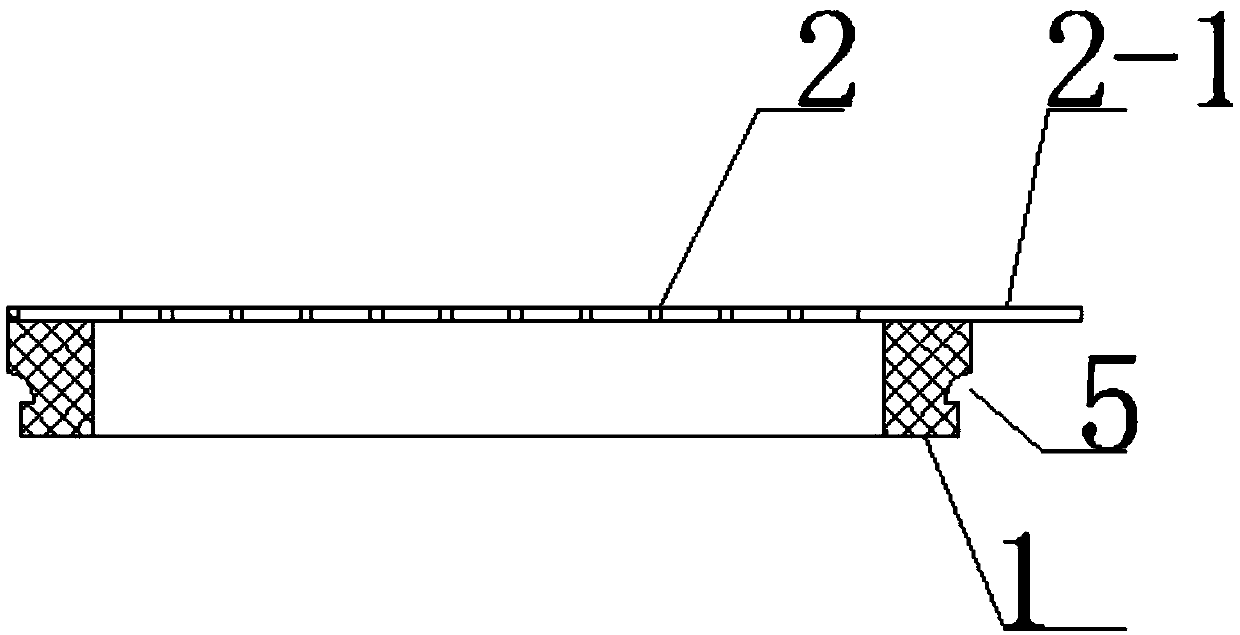

[0039] like Figure 1 to Figure 3 As shown, a sieve plate for preventing material from adhering, the sieve body 1 is a rectangular frame, and the sieve body 1 is provided with parallel and opposite supporting ribs 3 . The sieve surface 2 is connected to the sieve body 1 and has sieve holes on it. The screen surface 2 is made of polyurethane sheet with a thickness of 2mm-5mm. The screen surface 2 is supported on the support ribs 3, and the screen surface 2 and the support ribs 3 are separated. When the sieve plate vibrates, the screen surface 2 and the support ribs 3 can collide to prevent wet and sticky materials from falling on the screen surface. Adhesion.

[0040] The left and right sides of the sieve body 1 are provided with clamping grooves 5, and adjacent sieve bodies 1 can be fastened through the clamping grooves 5 and the clamping strips 7. The back of the screen surface 2 is provided with an extension part 2-1 extending out of the screen body 1, and the screen surf...

Embodiment 2

[0049] combine Figure 4 to Figure 7 As shown, a vibrating screen using a sieve plate of the embodiment, a plurality of support beams 6 are arranged in parallel and opposed to each other, and two support side plates 10 are symmetrically arranged on both sides of the support beam 6; the cross section of the support side plates 10 is "L" Type, the ends of the support beams 6 are installed on the supporting side plates 10. The support beam 6 is a hollow square tube, and the upper side of the support beam 6 offers a through groove. The lower end of the clip bar 7 is provided with a protrusion, and there is a through groove in the middle of the lower end of the clip bar 7 protrusions; The middle part of the clip bar 7 is a flat plate, and the upper part of the clip bar 7 is matched with the card slot 5; during installation, the left and right sides of the screen body 1 are overlapped on the adjacent support beams 6; the slots between two adjacent screen bodies 1 5 Cooperate with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com