Multidirectional automobile accessory cutting equipment adjusted by multiple guide rail lines

A technology for auto parts and cutting equipment, which is applied in the direction of metal sawing equipment, metal processing equipment, sawing machine devices, etc., can solve the problems of small adaptability, low flexibility and adjustability, and influence on cutting progress, and achieve high precision and adjustment Convenience, speed, and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

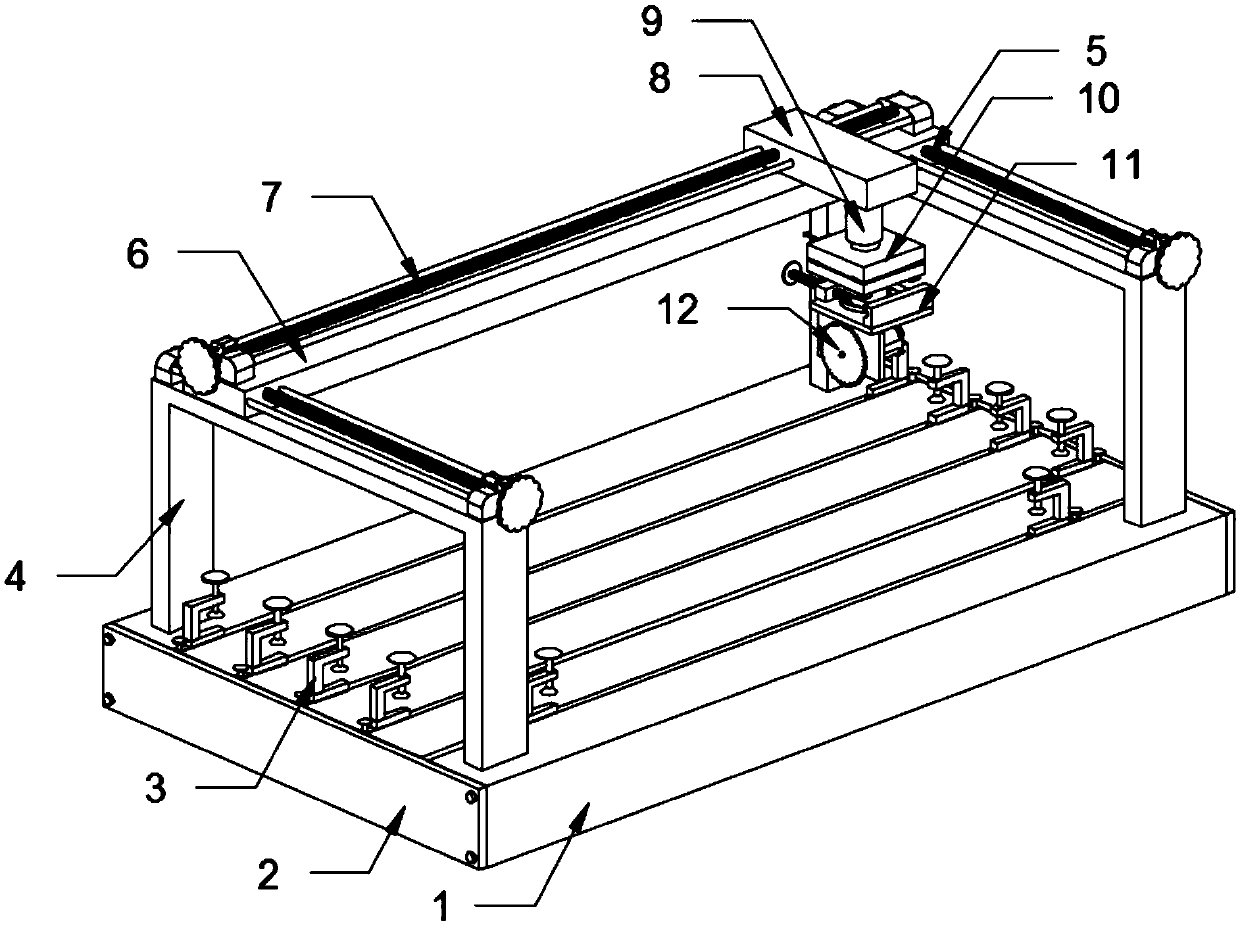

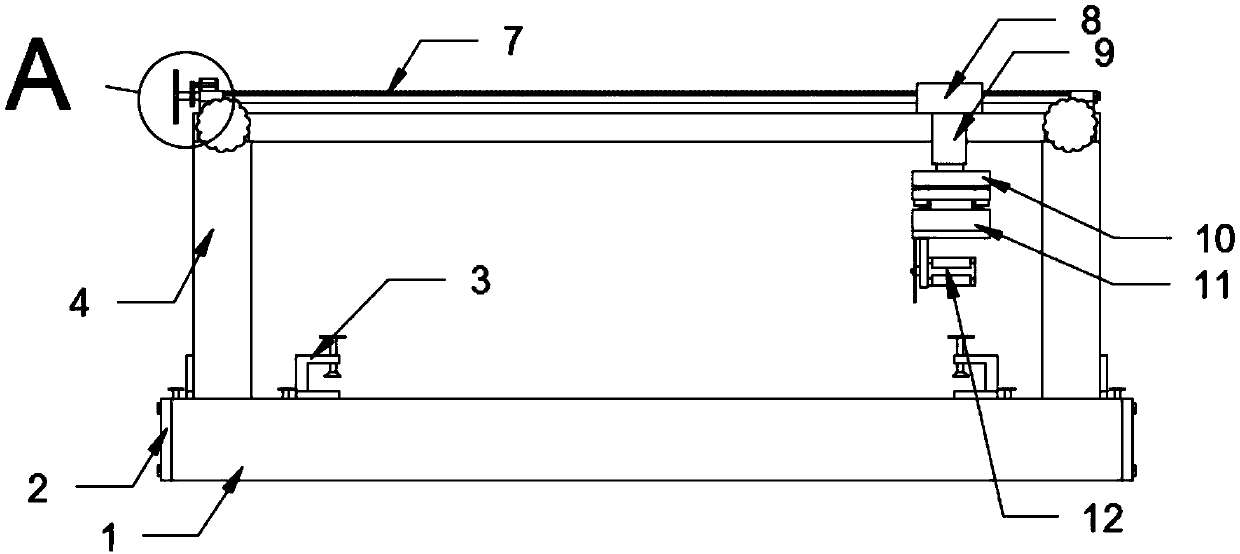

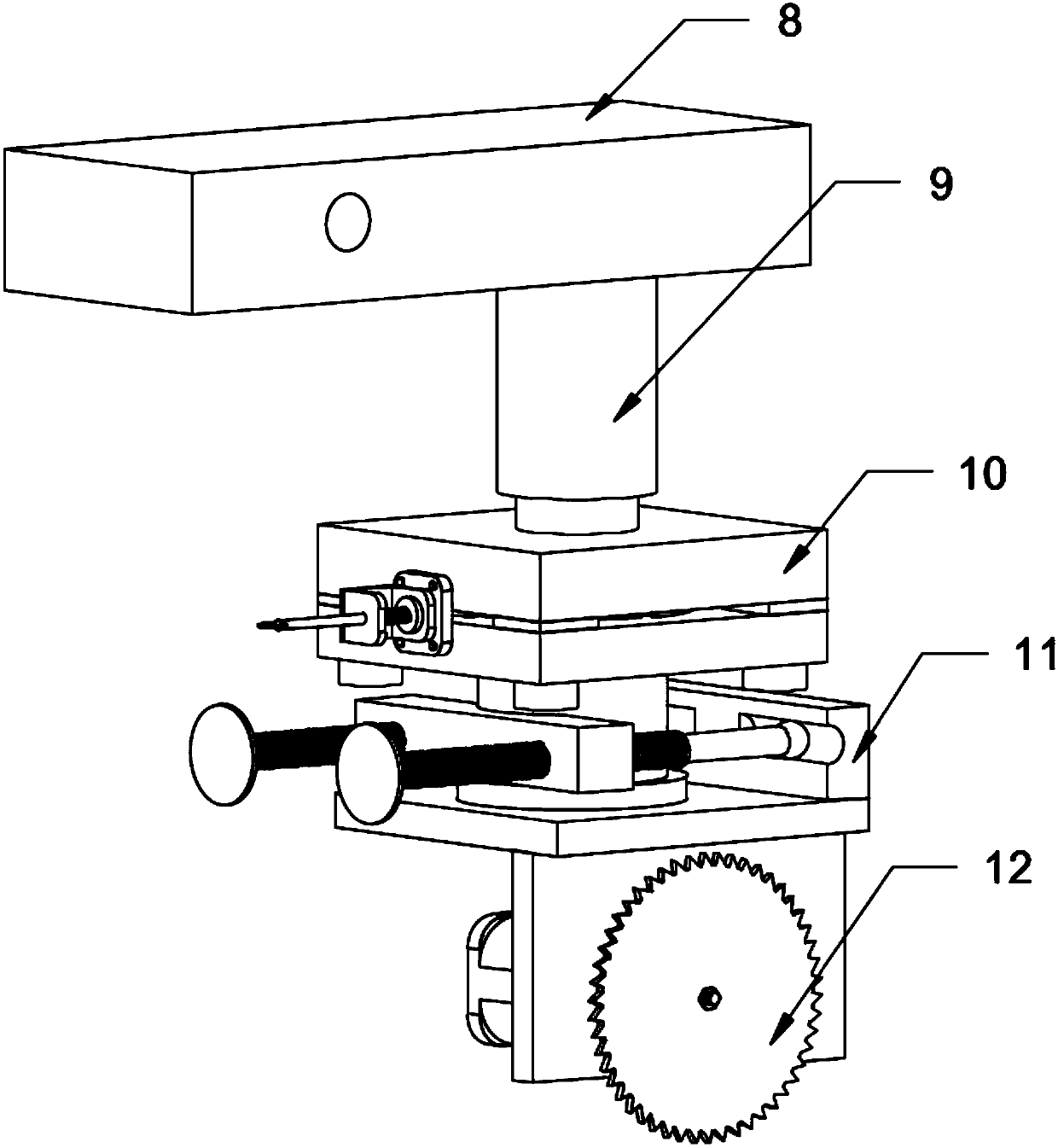

[0036] as attached figure 1 to attach Figure 9 Shown:

[0037] The invention provides a multi-directional auto parts cutting equipment adjusted by multiple guide rail lines, including: a bottom plate 1, a trapezoidal groove 101, a guard plate 2, a sliding fixing seat 3, a trapezoidal sliding seat 301, a spacer 302, a fixed arm 303, and bolts 304, supporting frame body 4, thread moving structure A5, fixed plate A501, cylindrical rod A502, threaded rod A503, gear A504, motor A505, rectangular rod A6, threaded moving structure B7, fixed plate B701, cylindrical rod B702, threaded rod B703 , gear B704, motor B705, rectangular rod B8, hydraulic telescopic rod 9, rotation adjustment assembly 10, cover plate 1001, cylindrical ring 1002, fixing gap 100201, cylindrical rod C1003, base 1004, elastic pin 1005, fine adjustment assembly 11, support Seat 1101, semicircular groove 110101, support plate 1102, stud 1103, iron ball 1104 and chainsaw main body 12; the top surface of base plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com