Power distribution station indoor equipment floor space collaborative routing inspection device and routing inspection method thereof

A technology of electrical equipment, ground and air, applied in the field of automatic inspection devices, can solve problems such as unguaranteed, affecting inspection tasks, instrumentation identification, etc., to ensure inaccurate or lost positioning, improve detection accuracy and efficiency, The effect of security assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

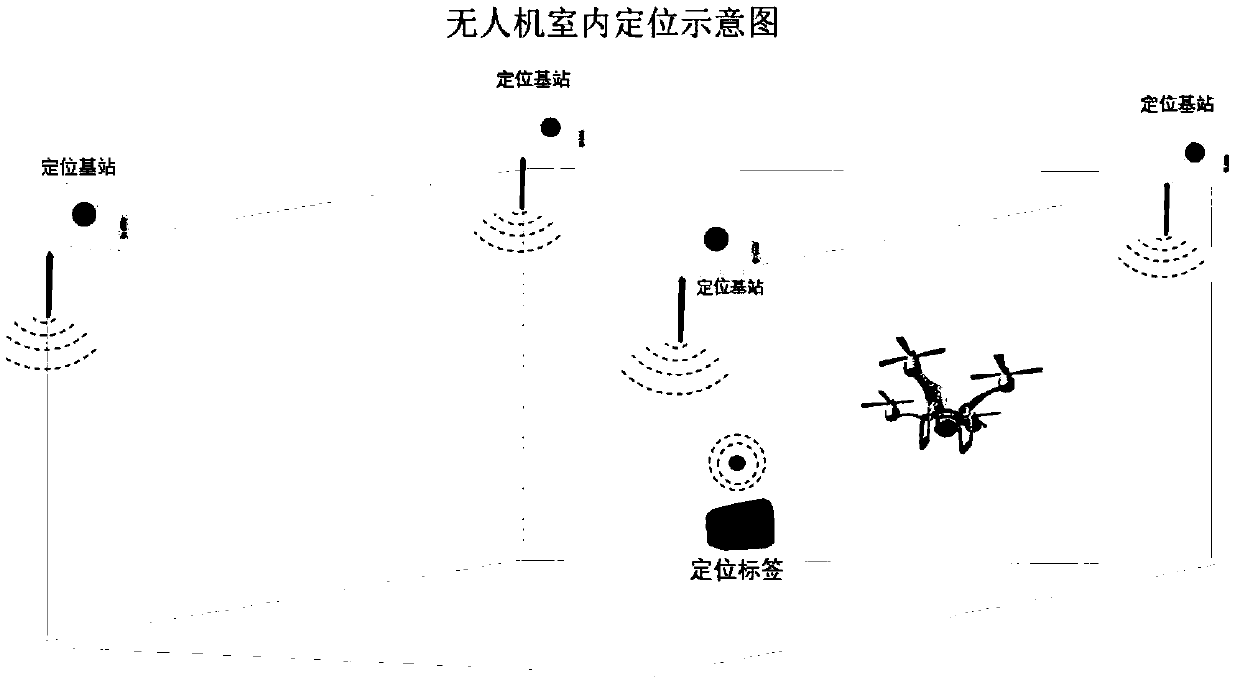

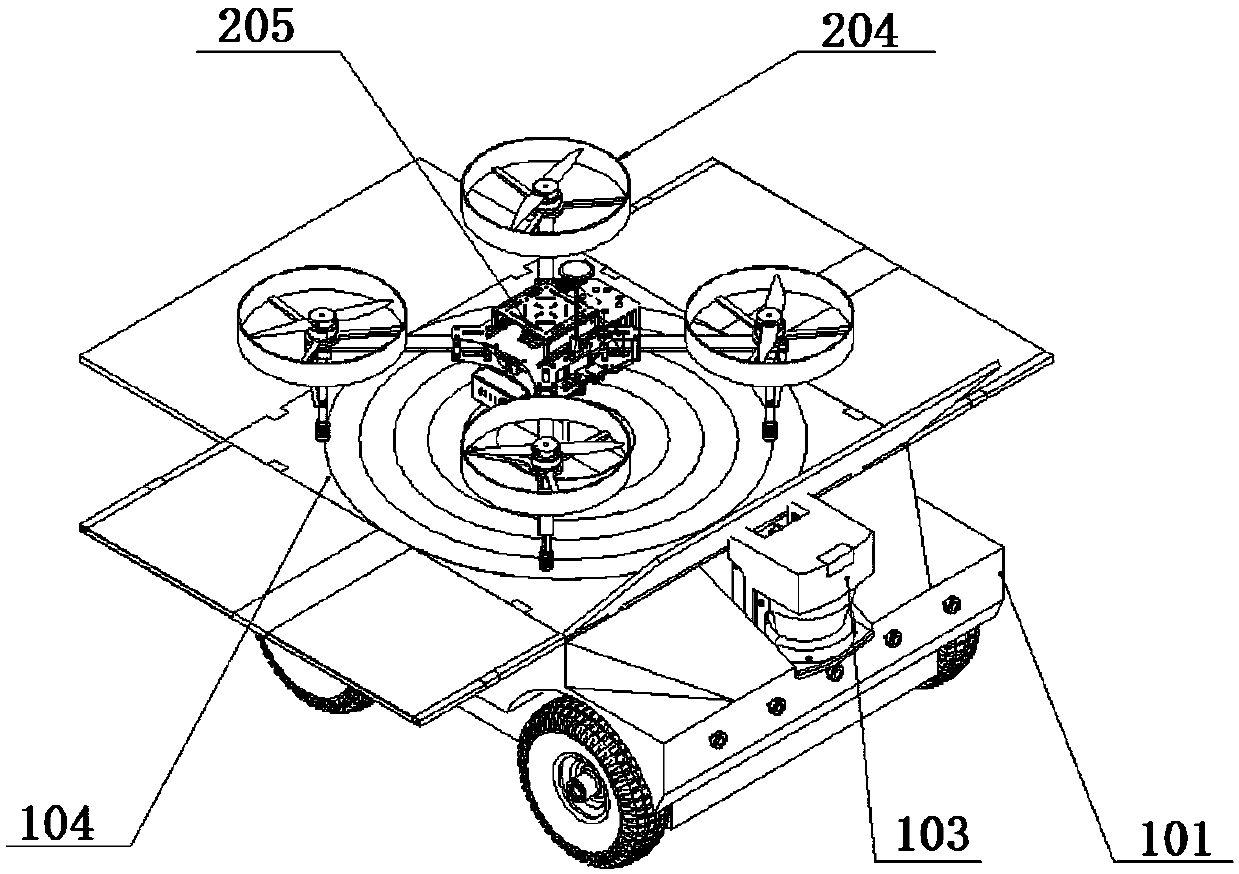

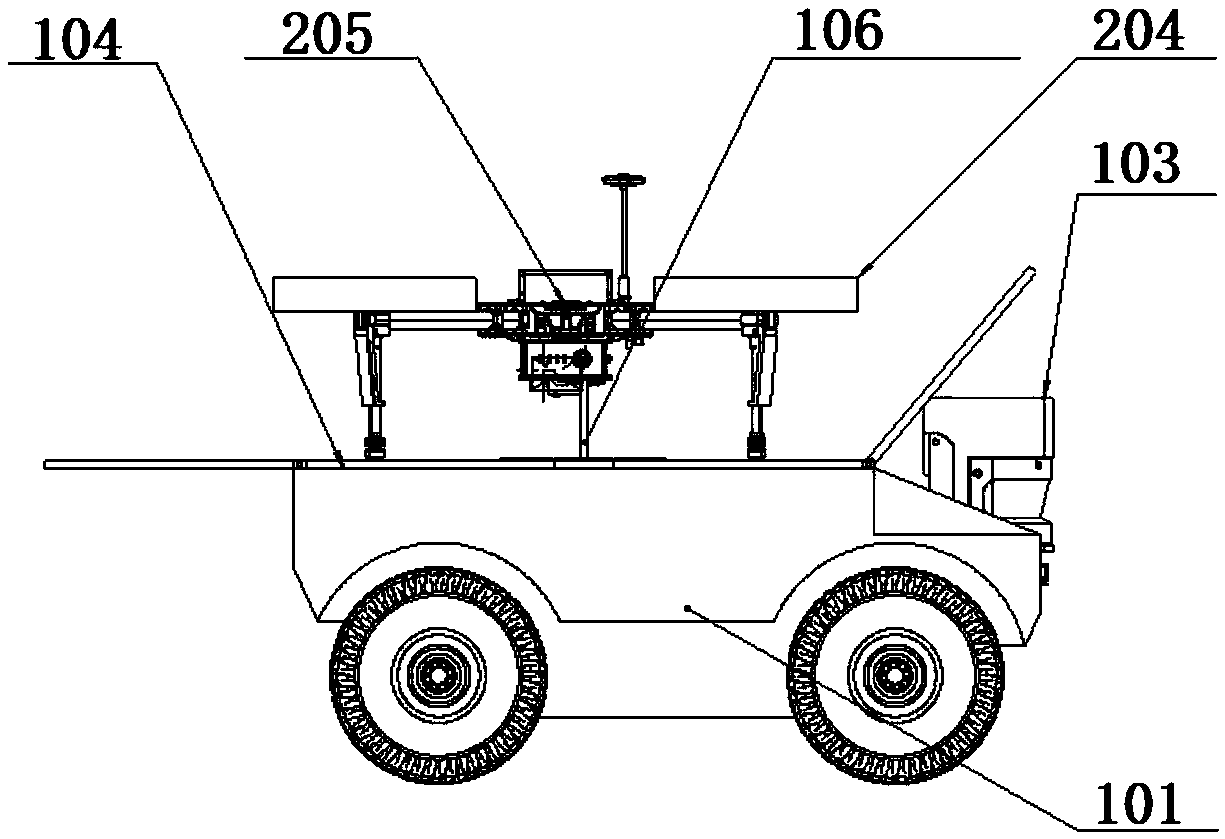

[0035] figure 2 , image 3It shows the ground-air collaborative inspection device for electrical equipment in the power distribution room. The robot adopts a four-wheel walking robot: the top of the robot body 101 is equipped with an apron 104 for the unmanned aerial vehicle to take off and land. The positioning mark 105 for the UAV to determine the position, the ultrasonic sensor 102 and the laser sensor 103 (ie laser radar) are installed on the front of the robot body 101; The protective case 204 has a UWB positioning label 205 on its top, and a landing gear 202 on its lower part; the inspection equipment 201 (with a camera on it for taking pictures) for power distribution room inspection is installed on the drone; The robot and the drone are connected through a retractable cable 206, and the retractable cable 206 is connected to the electric reel installed on the robot body 101. It is composed of the UAV power line for power supply and the communication line between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com