Integrated electric power braking system with novel coupling manner

A coupling method and electric power assist technology, which is applied in the direction of brakes, brake transmissions, transportation and packaging, etc., can solve the problems of low integration, difficult control, low recovery and utilization rate of regenerative braking energy, etc., to ensure safety performance and reliability, and the effect of improving cruising range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

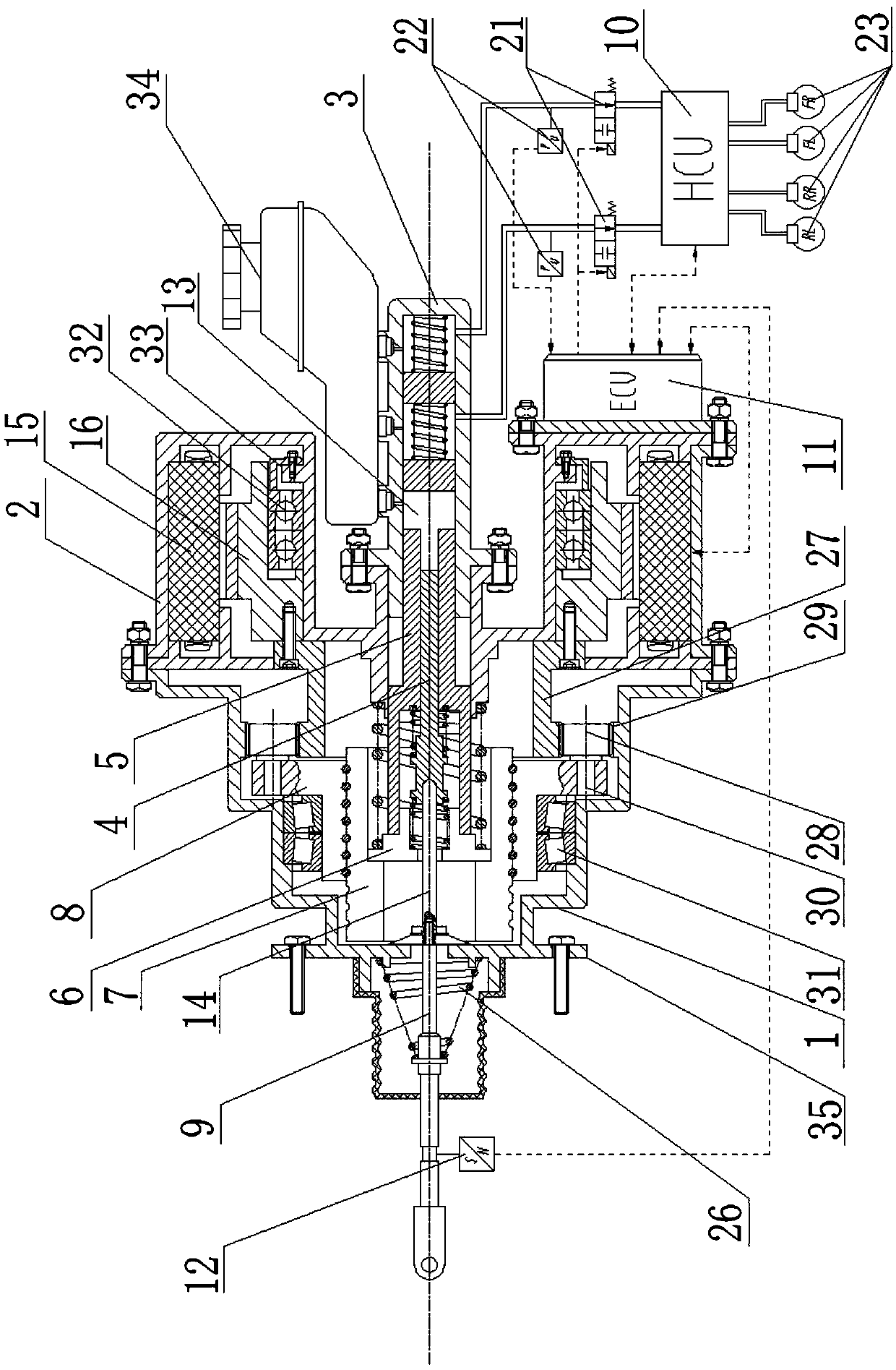

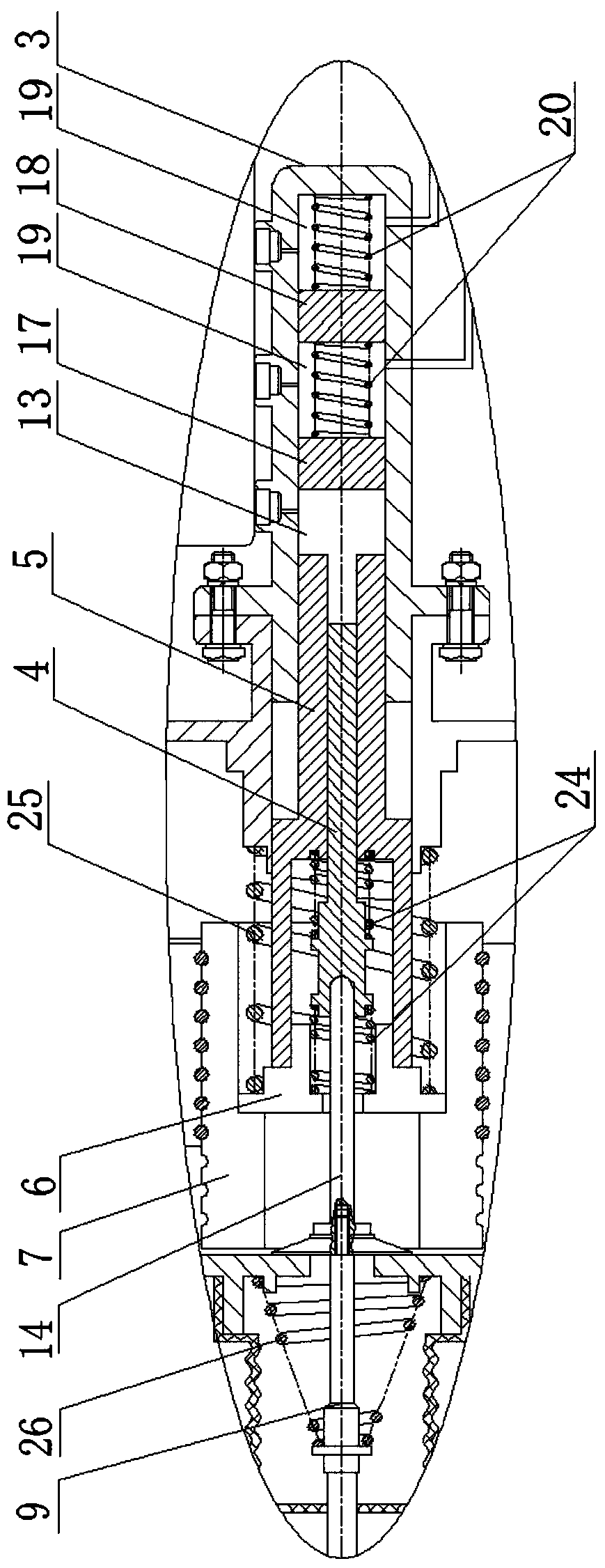

[0076] see Figure 1 to Figure 9 Shown:

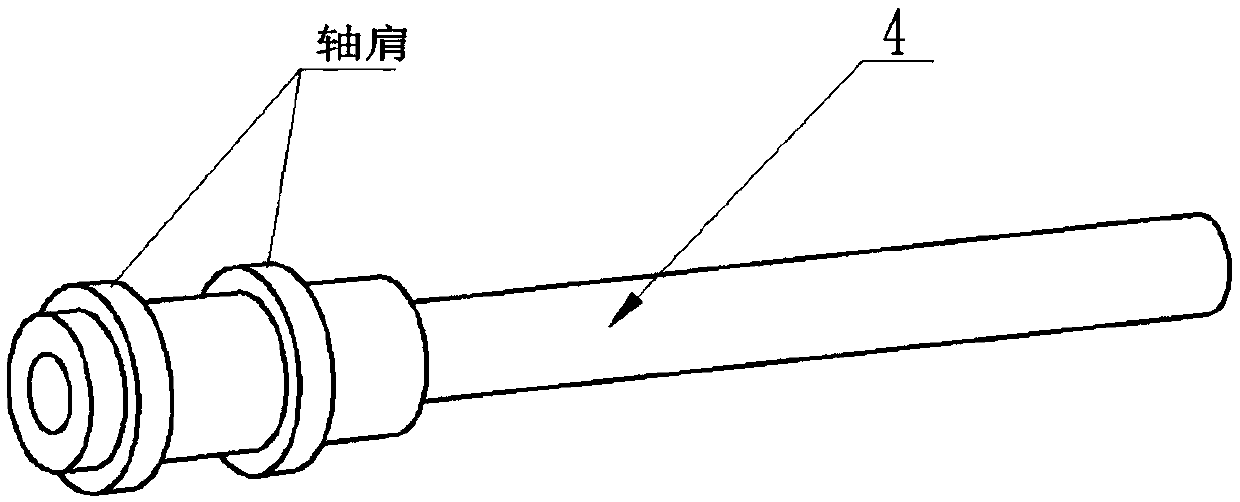

[0077] The present invention includes housing 1, hollow motor 2, brake master cylinder 3, manpower piston 4, booster piston 5, booster piston push rod 6, ball screw sub-screw 7, ball screw sub-nut 8, brake pedal push rod 9. Hydraulic control unit HCU10, electronic control unit ECU11, and pedal stroke sensor 12; wherein, the hollow motor 2 and the brake master cylinder 3 are respectively arranged at the rear of the housing 1, and the hollow motor 2 and the brake master cylinder 3 are coaxially arranged The master cylinder working chamber 13 at the front part of the brake master cylinder 3 is provided with a manpower piston 4 and a booster piston 5, and the booster piston 5 is provided with a through hole inside, and the manpower piston 4 is located in the through hole of the booster piston 5, and is connected with the booster piston 5 A clearance fit is formed to build pressure in the working chamber 13 of the master cylinder;

[0078...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com