Sound insulation door for ship's living cabin

A technology for sound insulation doors and cabins, applied in ship hatches/hatch, ship construction, ship parts, etc., can solve problems such as poor sound insulation effect of cabin doors, unreachable cabin noise values, and entry of external noise, etc. Simple and convenient installation, reduce transmission, and ensure the effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

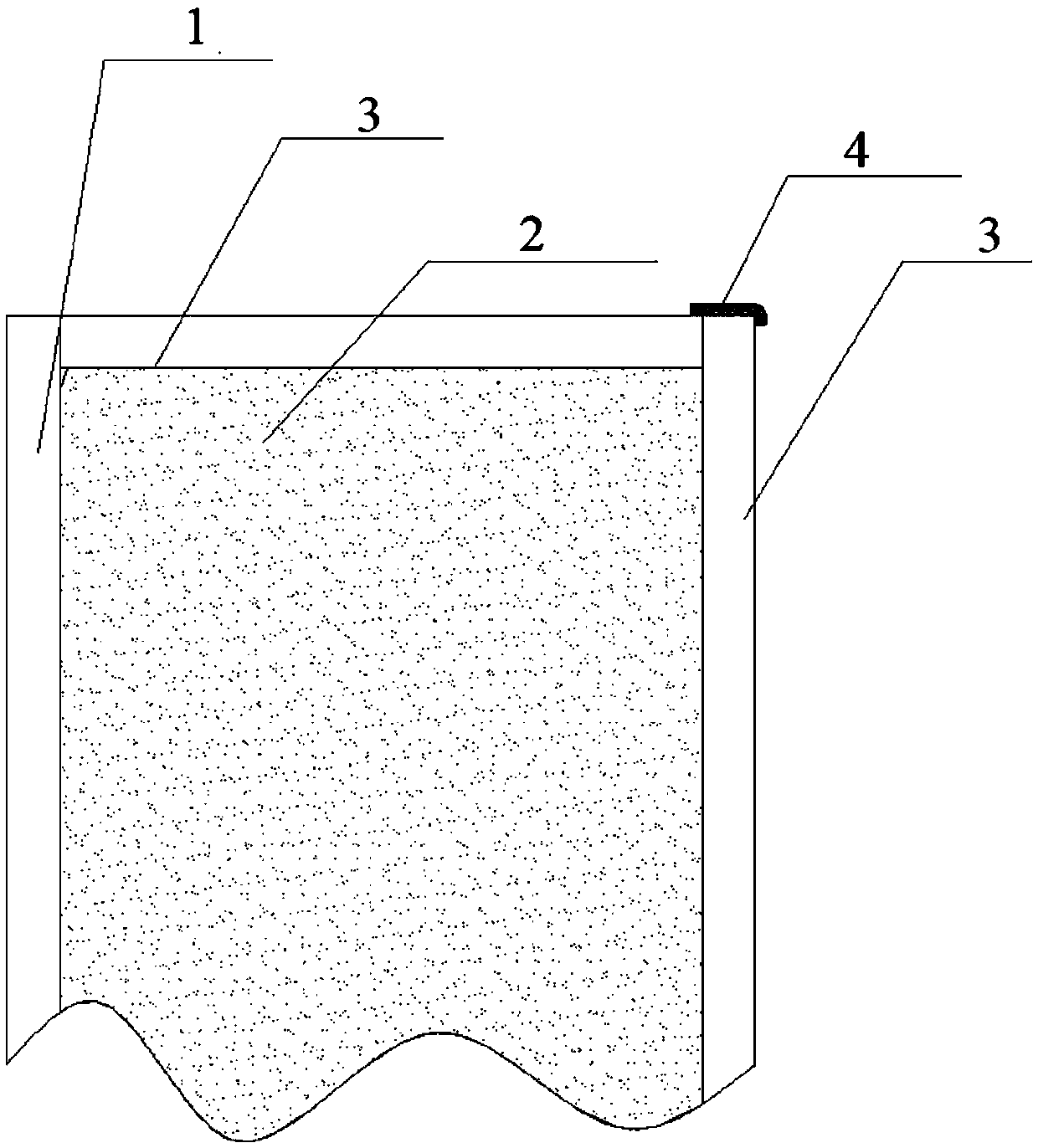

[0025] A soundproof door for a ship's cabin, the soundproof door mainly includes a steel door frame arranged on both sides of the cabin door, a door leaf and a door lock hinged on the door frame through a hinge.

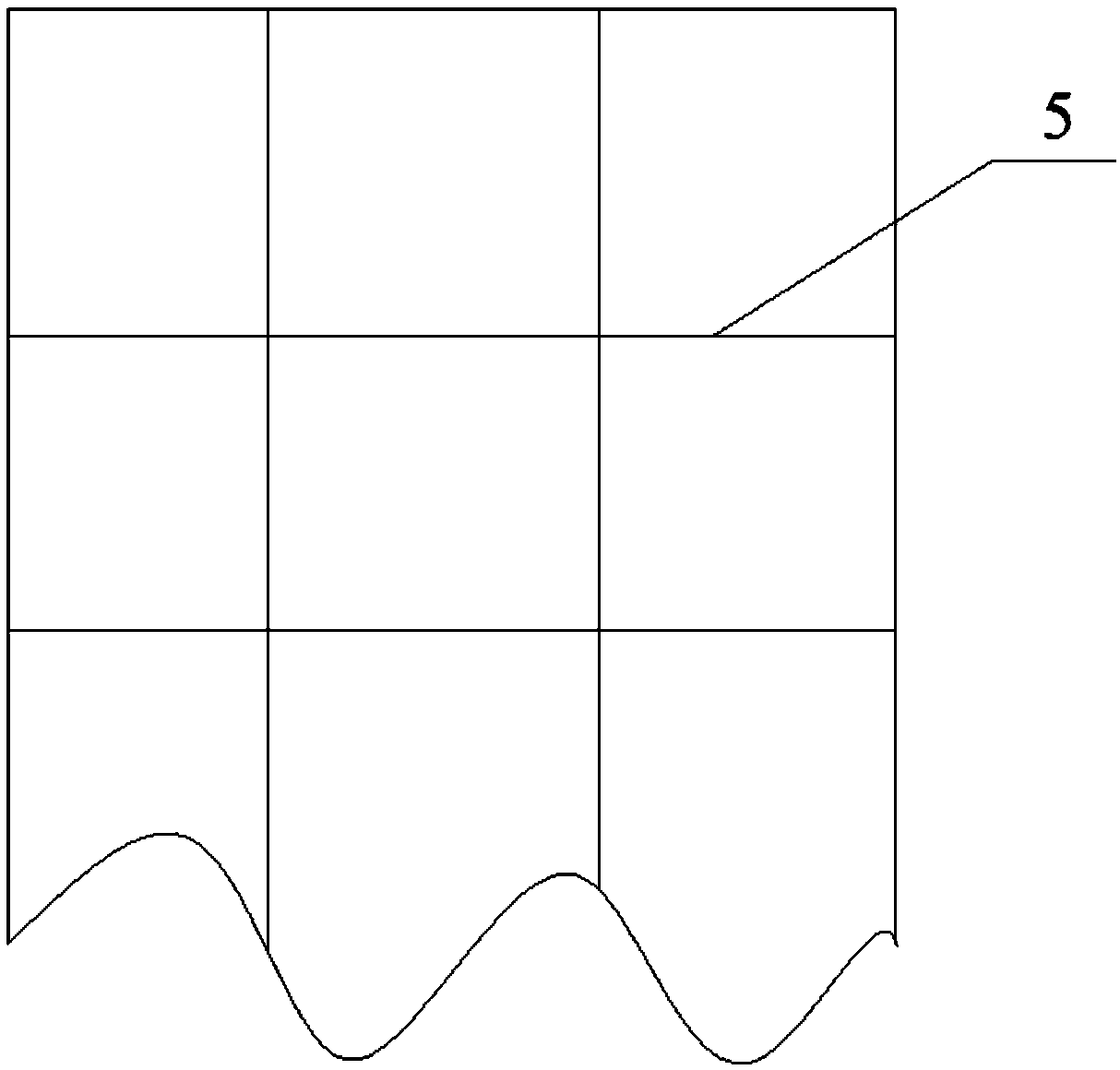

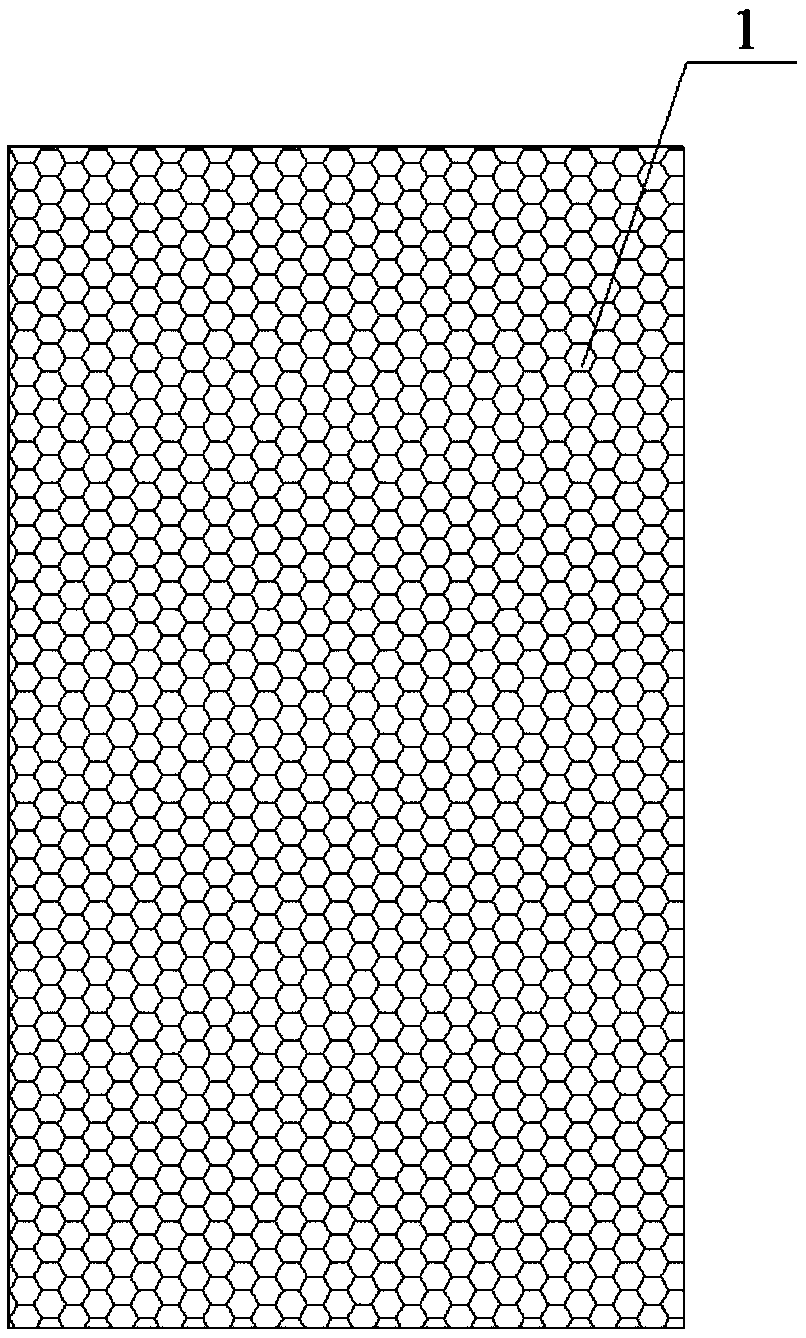

[0026] Among them, the door leaf is composed of a three-layer structure, the outer layer is 5mm thick aluminum honeycomb panel 1, the middle layer is 60mm thick porous sound-absorbing material 2, the inner layer is 5mm thick galvanized steel plate 3, welded on the galvanized steel plate 3 There is a grid-shaped steel frame 5, which is filled with porous sound-absorbing material 2, and the inside, outside, top and bottom of the porous sound-absorbing material 2 are clamped and welded by aluminum honeycomb panel 1 and galvanized steel plate 3.

[0027] There is a sealing rubber strip 4 at the contact between the door leaf and the door frame; there is a U-shaped groove around the inside of the door frame, and a sound-insulating fiber sealing strip 6 is installed. The sou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap