Low-electric-field high-dielectric adjustable zirconium-doped barium ferrite and preparation method thereof

A technology of barium ferrite and high dielectric, which is applied in the field of zirconium-doped barium ferrite ceramic materials and its preparation, can solve the problem of high modulation electric field, achieve high dielectric adjustability, simple process, high dielectric The effect of electrical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

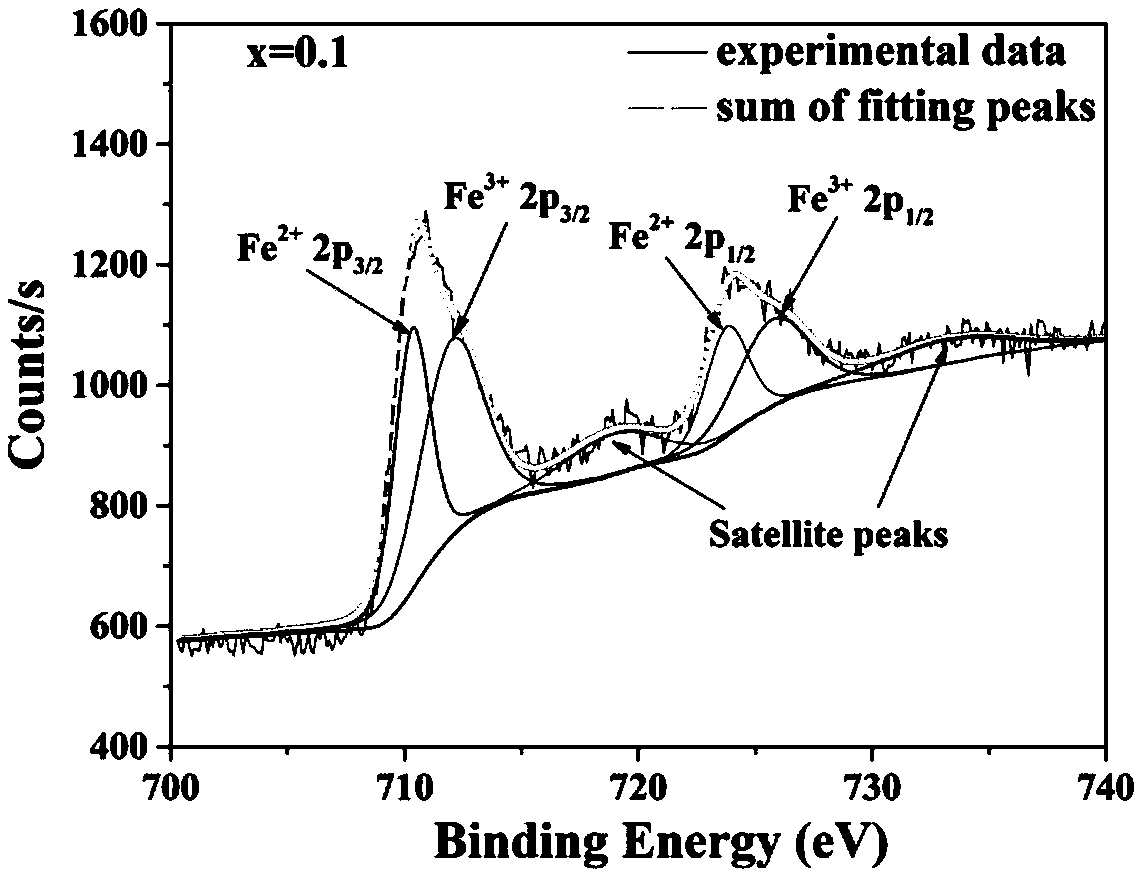

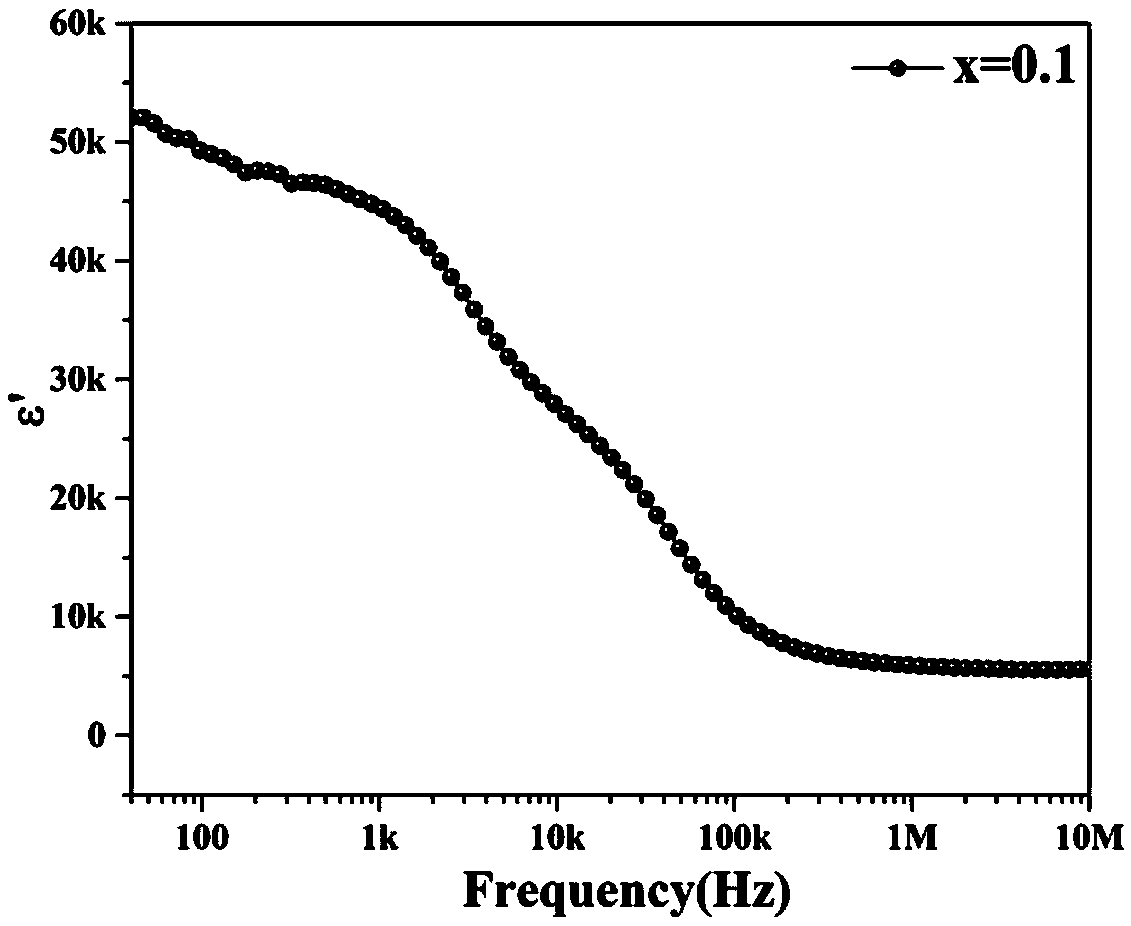

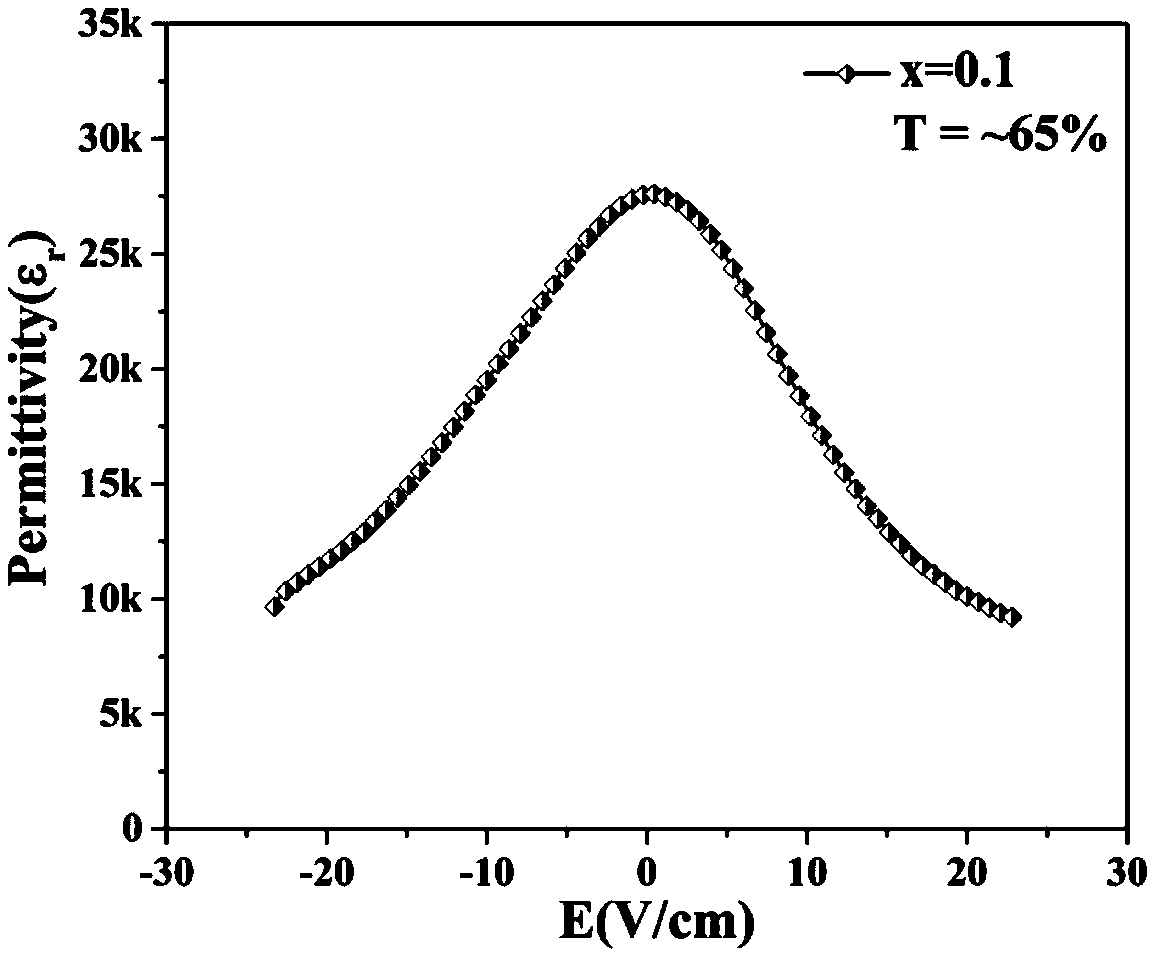

example 1

[0033] (1) Mix barium nitrate, ferric nitrate, zirconium nitrate and citric acid in a molar ratio of 1:11.9:0.1:19.05, add deionized water and stir until the solute is completely dissolved to obtain solution A.

[0034] (2) Adjust the pH of solution A to 7 to obtain solution B. Then, the solution B was heated and stirred in a water bath at 90° C. for 4 h to evaporate the solvent to obtain a sol precursor. The resulting sol precursor was dried at 120 °C for 4 days to obtain a fluffy black gel.

[0035] (3) Grinding the obtained xerogel in a mortar, and then putting it into a muffle furnace for pre-calcination. The pre-burning is specifically: raising the temperature to 210°C at a heating rate of 8°C / min, and keeping it at this temperature for 2h, then raising the temperature to 450°C at a heating rate of 6°C / min, and keeping it at this temperature for 2.5h, so that The dry gel is completely burned and decomposed, and finally the temperature is raised to 800°C at a heating rat...

example 2

[0042] (1) Mix barium nitrate, ferric nitrate, zirconium nitrate and citric acid in a molar ratio of 1:11.8:0.2:19.1, add deionized water and stir until the solute is completely dissolved to obtain solution A.

[0043] (2) Adjust the pH of solution A to 6 to obtain solution B. Then, the solution B was heated and stirred in a water bath at 80° C. for 3.5 h to evaporate the solvent to obtain a sol precursor. The resulting sol precursor was dried at 118 °C for 5 days to obtain a fluffy black gel.

[0044] (3) Grinding the obtained black gel in a mortar, and then putting it into a muffle furnace for pre-calcination. The pre-burning is specifically: raising the temperature to 210°C at a heating rate of 6°C / min, and keeping it at this temperature for 2.5h, then raising the temperature to 450°C at a heating rate of 8°C / min, and keeping it at this temperature for 2h, so that The black gel was completely burned and decomposed, and finally the temperature was raised to 800°C at a heat...

example 3

[0050] (1) Mix barium nitrate, ferric nitrate, zirconium nitrate and citric acid in a molar ratio of 1:11.9:0.1:19.05, add deionized water and stir until the solute is completely dissolved to obtain solution A.

[0051] (2) Adjust the pH of solution A to 7 to obtain solution B. Then, the solution B was heated and stirred in a water bath at 75° C. for 3 h to evaporate the solvent to obtain a sol precursor. The resulting sol precursor was dried at 115 °C for 6 days to obtain a fluffy black gel.

[0052] (3) Grinding the obtained black gel in a mortar, and then putting it into a muffle furnace for pre-calcination. Pre-burning is specifically: raising the temperature to 210°C at a heating rate of 6°C / min, and keeping it at this temperature for 2 hours, then raising the temperature to 450°C at a heating rate of 5°C / min, and keeping it at this temperature for 2 hours, so that black The gel is completely burned and decomposed, and finally the temperature is raised to 800°C at a hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com