Preparation method of thermally-stable high-toughness ceramic glaze

A ceramic glaze, high toughness technology, applied in the field of preparation of thermally stable high toughness ceramic glaze, can solve the problems of insufficient toughness, poor thermal stability, etc., achieve good thermal stability, improve thermal stability, Si-O bond The effect of key energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

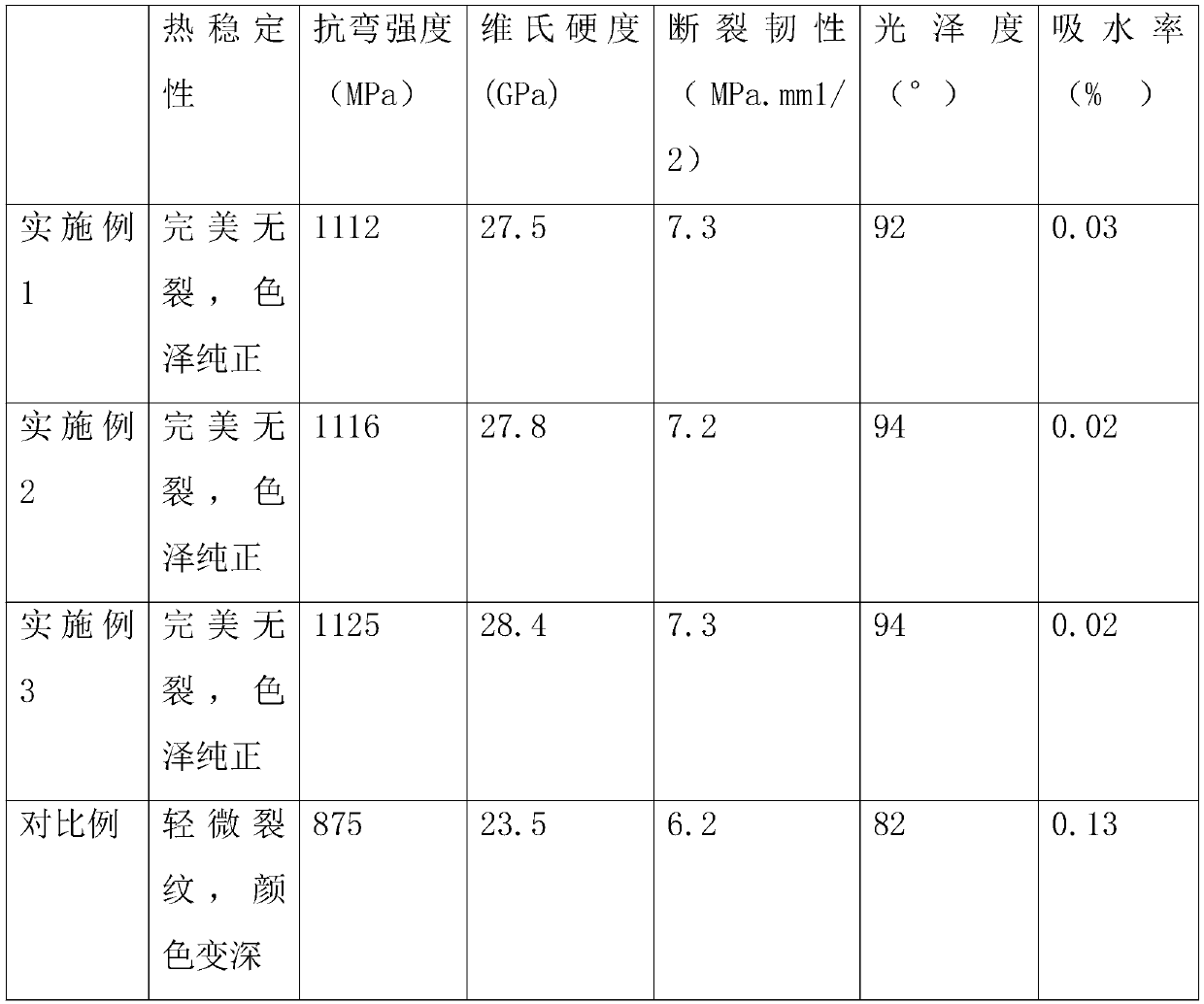

Examples

Embodiment 1

[0022] Dissolve 5 parts of zirconium oxychloride in 28 parts of deionized water; add a water-soluble additive to the above-mentioned zirconium oxychloride solution; add 2 parts of ammonia water with a concentration of 25% to the zirconia solution for reaction, while controlling the reaction temperature to 40°C, after adding ammonia water dropwise, then crystallize at 40°C for 0.5hr at a constant temperature, and form zirconium hydroxide hydrogel after the reaction is completed; wash the zirconium hydroxide hydrogel with deionized water until the conductivity of the aqueous solution is 20us / cm; After pressure filtration or centrifugal separation, zirconium hydroxide gel is obtained; dry the zirconium hydroxide gel at 80°C to obtain zirconium hydroxide; calcinate the dried zirconium hydroxide at 700°C, and keep the temperature at 700°C for 1.5hr , calcined to obtain zirconium dioxide; take 5 parts of sodium silicate, 5 parts of ammonia water with a mass fraction of 20 to 25%, and...

Embodiment 2

[0024] Dissolve 4 parts of zirconium oxychloride in 21 parts of deionized water; add a water-soluble additive to the above-mentioned zirconium oxychloride solution; add 2 parts of ammonia water with a concentration of 25% to the zirconia solution for reaction, while controlling the reaction temperature to 65°C, after adding ammonia water dropwise, then crystallize at 65°C for 0.5hr at a constant temperature. After the reaction is completed, zirconium hydroxide hydrogel is formed; wash the zirconium hydroxide hydrogel with deionized water until the conductivity of the aqueous solution is 20us / cm; After pressure filtration or centrifugation, zirconium hydroxide gel is obtained; dry the zirconium hydroxide gel at 100°C to obtain zirconium hydroxide; calcinate the dried zirconium hydroxide at 700°C, and keep the temperature at 1200°C for 1.5hr , calcined to obtain zirconium dioxide; take 3 parts of sodium silicate, 4 parts of ammonia water with a mass fraction of 20 to 25%, and 17 ...

Embodiment 3

[0026]Dissolve 8 parts of zirconium oxychloride in 35 parts of deionized water; add a water-soluble additive to the above-mentioned zirconium oxychloride solution; add 2 parts of ammonia water with a concentration of 25% to the zirconia solution for reaction, and control the reaction temperature at the same time. 65°C, after adding ammonia water dropwise, then crystallize at 65°C for 0.5hr at a constant temperature. After the reaction is completed, zirconium hydroxide hydrogel is formed; wash the zirconium hydroxide hydrogel with deionized water until the conductivity of the aqueous solution is 20us / cm; After pressure filtration or centrifugation, zirconium hydroxide gel is obtained; dry the zirconium hydroxide gel at 100°C to obtain zirconium hydroxide; calcinate the dried zirconium hydroxide at 700°C, and keep the temperature at 1200°C for 1.5hr , calcined to obtain zirconium dioxide; take 8 parts of sodium silicate, 6 parts of ammonia water with a mass fraction of 20-25%, an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap