Leaf surface water flush fertilizer

A technology of flushing fertilization and leaf surface application in the direction of fertilization devices, nitrogen fertilizers, and phosphate fertilizers. It can solve the problems of sterilization, inhibition of poison, lower production efficiency, and slow reaction efficiency, and achieve the goal of promoting rapid response, improving mixing effect, and ensuring purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

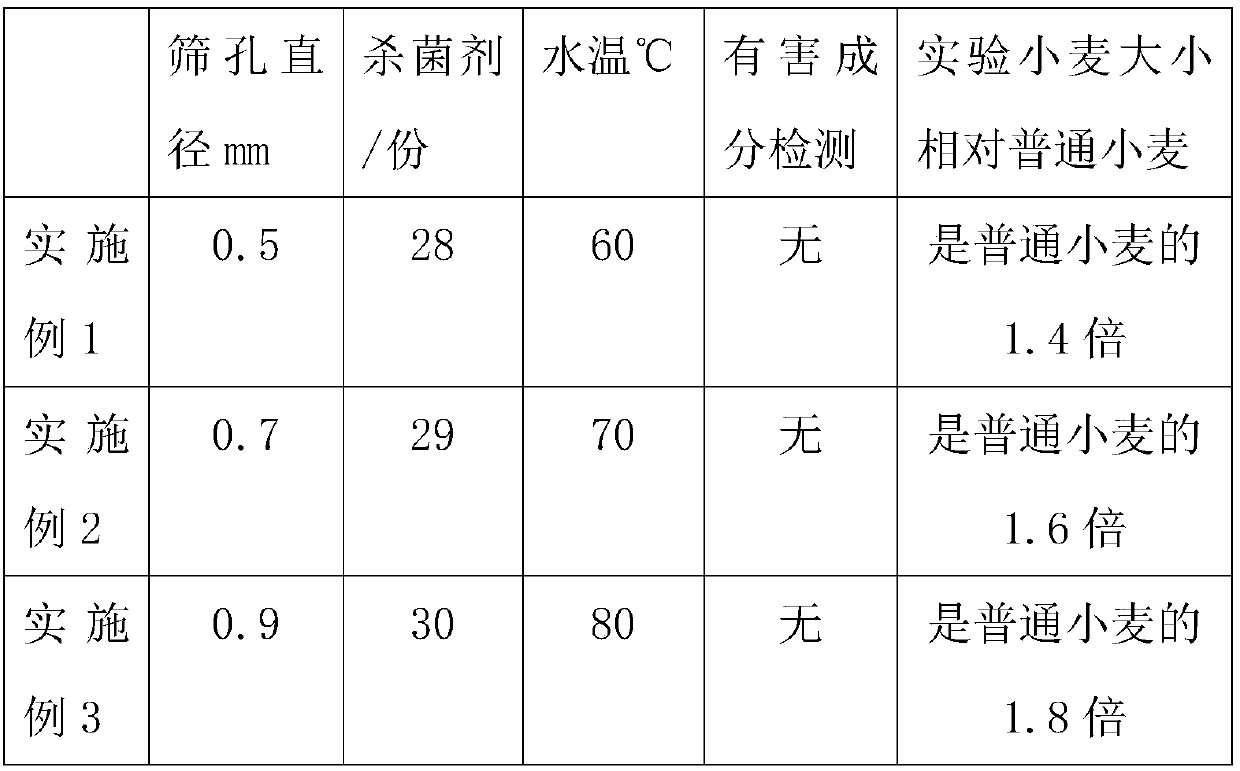

Embodiment 1

[0024] A kind of foliar fertilization, prepared from the following raw materials in parts by weight: 47 parts of carbonamide, 15 parts of monoammonium phosphate, 16 parts of potassium dihydrogen phosphate, 13 parts of potassium nitrate, 3 parts of boric acid, and plant growth regulator 15 parts and 28 parts of fungicides, the plant growth regulator is one or more of sodium nitrophenolate, brassinolate and gibberellin, and the fungicides are copper sulfate, enoyl manganese zinc and ethyl phosphorus One or more types of aluminum.

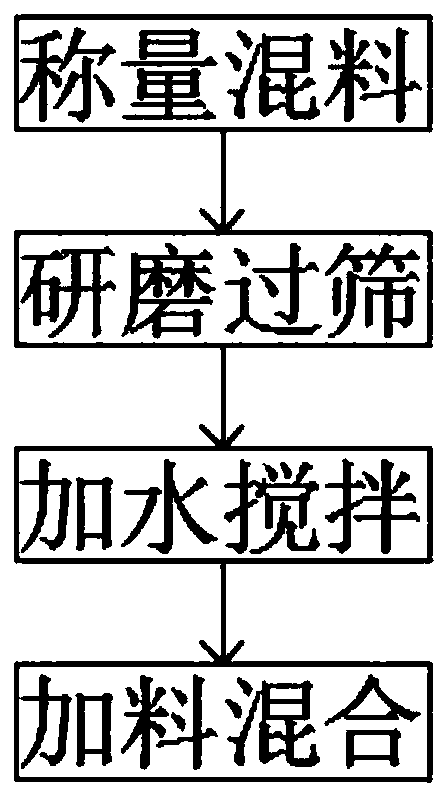

[0025] A preparation method for foliage fertilization, the specific steps are as follows:

[0026] (1) Weighing and mixing: according to the weight parts, weigh the following raw materials: carbonamide, monoammonium phosphate, potassium dihydrogen phosphate, potassium nitrate and boric acid, and mix them evenly. Before mixing, the weighed raw materials should be destoned Treatment and chip removal;

[0027] (2) Grinding and sieving: Put the uniforml...

Embodiment 2

[0031] A kind of foliar fertilization, prepared from the following raw materials in parts by weight: 48 parts of carbonamide, 16 parts of monoammonium phosphate, 17 parts of potassium dihydrogen phosphate, 14 parts of potassium nitrate, 4 parts of boric acid, plant growth regulator 16 parts and 29 parts of fungicides, the plant growth regulator is one or more of sodium nitrophenolate, brassinolate and gibberellin, and the fungicides are copper sulfate, enoyl manganese zinc and ethyl phosphorus One or more types of aluminum.

[0032] A preparation method for foliage fertilization, the specific steps are as follows:

[0033] (1) Weighing and mixing: according to the weight parts, weigh the following raw materials: carbonamide, monoammonium phosphate, potassium dihydrogen phosphate, potassium nitrate and boric acid, and mix them evenly. Before mixing, the weighed raw materials should be destoned Treatment and chip removal;

[0034] (2) Grinding and sieving: Put the uniformly mi...

Embodiment 3

[0038] A kind of foliar fertilization, prepared from the following raw materials in parts by weight: 49 parts of carbonamide, 17 parts of monoammonium phosphate, 18 parts of potassium dihydrogen phosphate, 15 parts of potassium nitrate, 5 parts of boric acid, plant growth regulator 17 parts and 30 parts of fungicides, the plant growth regulator is one or more of sodium nitrophenolate, brassinolate and gibberellin, and the fungicides are copper sulfate, enoyl manganese zinc and ethyl phosphorus One or more types of aluminum.

[0039] A preparation method for foliage fertilization, the specific steps are as follows:

[0040] (1) Weighing and mixing: according to the weight parts, weigh the following raw materials: carbonamide, monoammonium phosphate, potassium dihydrogen phosphate, potassium nitrate and boric acid, and mix them evenly. Before mixing, the weighed raw materials should be destoned Treatment and chip removal;

[0041] (2) Grinding and sieving: Put the uniformly mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com