Method for strengthening bubbling internal circulation of fluidized bed gasification furnace and fluidized bed gasification furnace

A fluidized bed gasifier and internal circulation technology, which is applied in the field of coal gasification, can solve the problems of slow coal circulation speed, coal powder slagging, and reduced gas production efficiency, so as to improve gasification efficiency, promote agitation, and improve The effect of movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

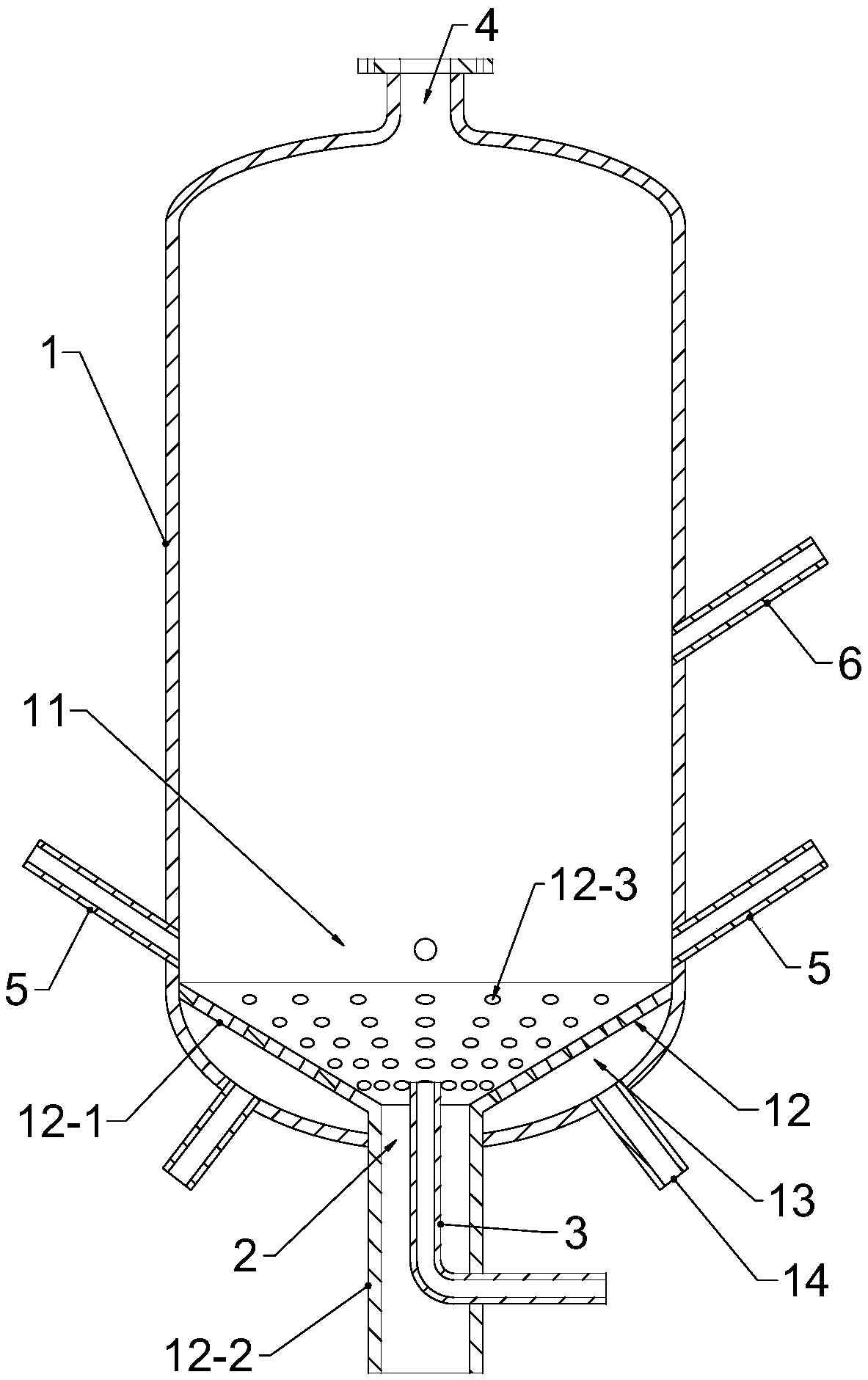

[0020] Such as figure 1 As shown, the method of strengthening the bubbling internal circulation of the fluidized bed gasifier is to install a plurality of inlet pipes 5 along the direction of the pulverized coal circulation in the dense-phase area of the gasifier 1 to form a gas path. The air intake pipe 5 blows air into the furnace body, and the airflow is used to drive the pulverized coal to accelerate circulation.

[0021] The working principle of this embodiment is: the airflow drives the pulverized coal to accelerate circulation, promotes the rapid circulation of the crushed coal in the bubbling area through the central high-temperature zone, and at the same time shortens the residence time of the pulverized coal in the central high-temperature zone, reduces the phenomenon of pulverized coal slagging, and reduces the size of the coal. The temperature difference between different positions of powder in the gasifier can be improved to improve the gas production efficiency...

Embodiment 2

[0023] Such as figure 1 As shown, the fluidized bed gasification furnace includes a vertical cylindrical furnace body 1, a slag outlet 2 is opened at the bottom of the furnace body 1; a central jet tube 3 is arranged inside the slagging outlet 2, and a There is an exhaust port 4; several air intake pipes 5 are connected to the lower side wall of the furnace body, and the air intake pipes are evenly distributed along the circumference of the cylinder body 1, and the end of the air intake pipe 5 located outside the furnace body 1 is inclined upward, so that the air intake direction is inclined downward The side wall of body of furnace 1 is provided with several feed pipes 6, and feed pipe 6 conveys pulverized coal into the bubbling dense-phase area in body of furnace 1 to carry out gasification reaction, and described air inlet pipe 5 is connected in the furnace obliquely downward. On the side wall of the furnace body 1; the furnace body 1 is lined with a high-temperature resist...

Embodiment 3

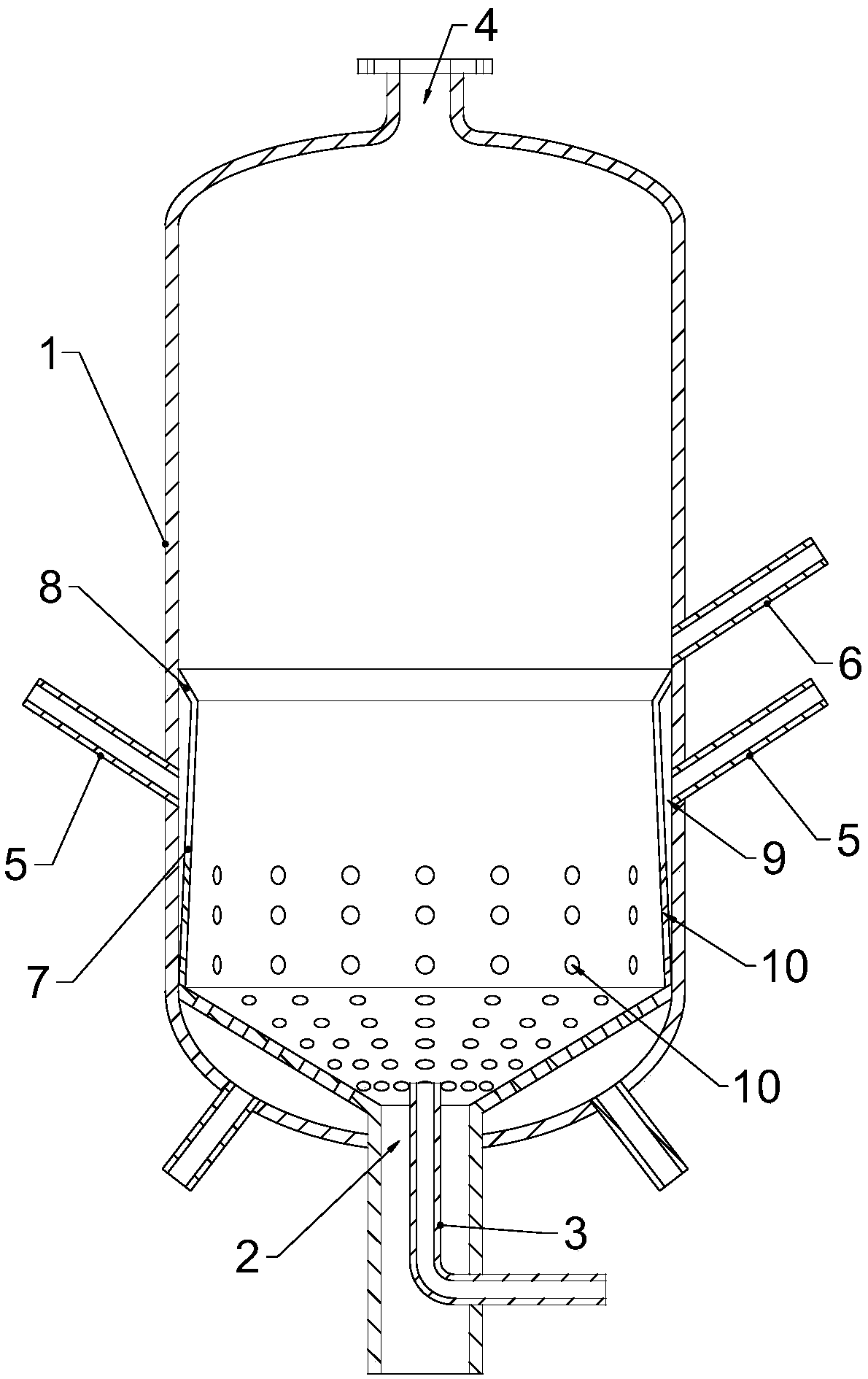

[0027] Such as figure 2 As shown, the fluidized bed gasification furnace includes a vertically arranged cylindrical furnace body. The bottom of the furnace body 1 is provided with a slag discharge port 2. A central jet tube 3 is arranged inside the slag discharge port 2. A discharge port 3 is provided at the top of the furnace body 1. Gas port 4, several intake pipes 5 are connected to the lower side wall of the furnace body 1, the intake pipes are evenly distributed along the circumference of the cylinder body 1, and several feed pipes 6 are arranged on the side wall of the furnace body 1, and the feed pipes 6 will be broken The coal is transported into the bubbling dense-phase area in the furnace body 1 for gasification reaction. The furnace body 1 is provided with an inner cylinder 7, and the upper end of the inner cylinder 7 is turned outward to form an annular flanging 8. The outer edge of the annular flanging 8 The edge is fixedly connected to the inner wall of the furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com