Anti-supply-halt coal powder recovery storage system applied to metallurgy

A technology for pulverized coal and storage, which is applied in the field of coal powder recovery and reserve system for preventing material failure, can solve the problems of poor grinding quality, blast furnace shutdown, and insufficient qualified pulverized coal, so as to reduce the risk of material failure and reduce pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

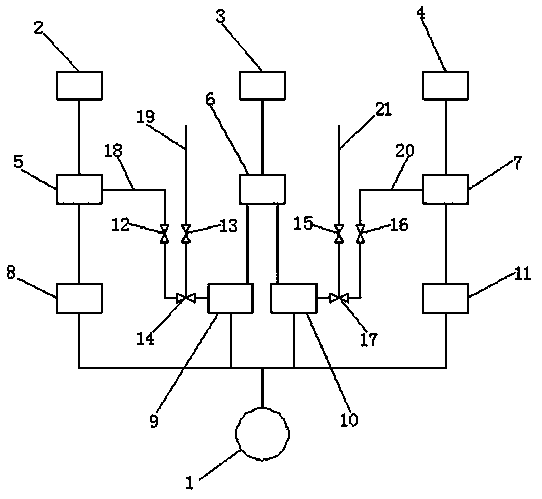

[0024] Such as figure 1 shown, as figure 1 As shown, an anti-cutting coal powder recovery storage system applied to metallurgy includes a coal injection bin 1, a main grinding conveying line and an auxiliary grinding conveying line, both of which include a grinder, a powder collecting Bin and bin-type pump, the grinder grinds coal into coal powder, which is transported to the powder collection bin for temporary storage through the pipeline, and the powder collection bin transports the temporarily stored coal powder to the bin-type pump through the pipeline, driven by the bin-type pump It is transported to the coal injection bin 1 through pipelines, wherein the bin pump of the main grinding conveying line is connected with the powder collecting bin of the auxiliary grinding conveying line through seamless pipes.

[0025] In use, the bin pump of the main grinding conveying line is connected with the powder collecting bin of the auxiliary grinding conveying line through a seamle...

Embodiment 2

[0027] Based on Embodiment 1, the main grinding conveying line includes the first grinder 3, the first powder collecting bin 6 and the first chamber pump 9, and the auxiliary grinding conveying line includes the second grinding machine 2, the second powder collecting bin 5 and the second The chamber pump 8, the first chamber pump 9 communicates with the second powder collecting chamber 5 through the first seamless pipe 18, the first seamless pipe 18 is connected with the first compressed air pipe 19, and the first seamless pipe 18 The first air supply device 14 is arranged at the connection with the first compressed air pipe 19, and the first air supply device 14 guides the coal powder in the first storehouse pump 9 into the second collection unit through the compressed air introduced by the first compressed air pipe 19. Inside the powder bin 5.

[0028] In use, a part of the pulverized coal produced by the first grinder is sent to the first powder collection bin for temporary...

Embodiment 3

[0030] Based on the second embodiment, the first seamless pipe 18 is also provided with a first pneumatic valve 12 , and the first compressed air pipe 19 is provided with a first positioning ball valve 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com