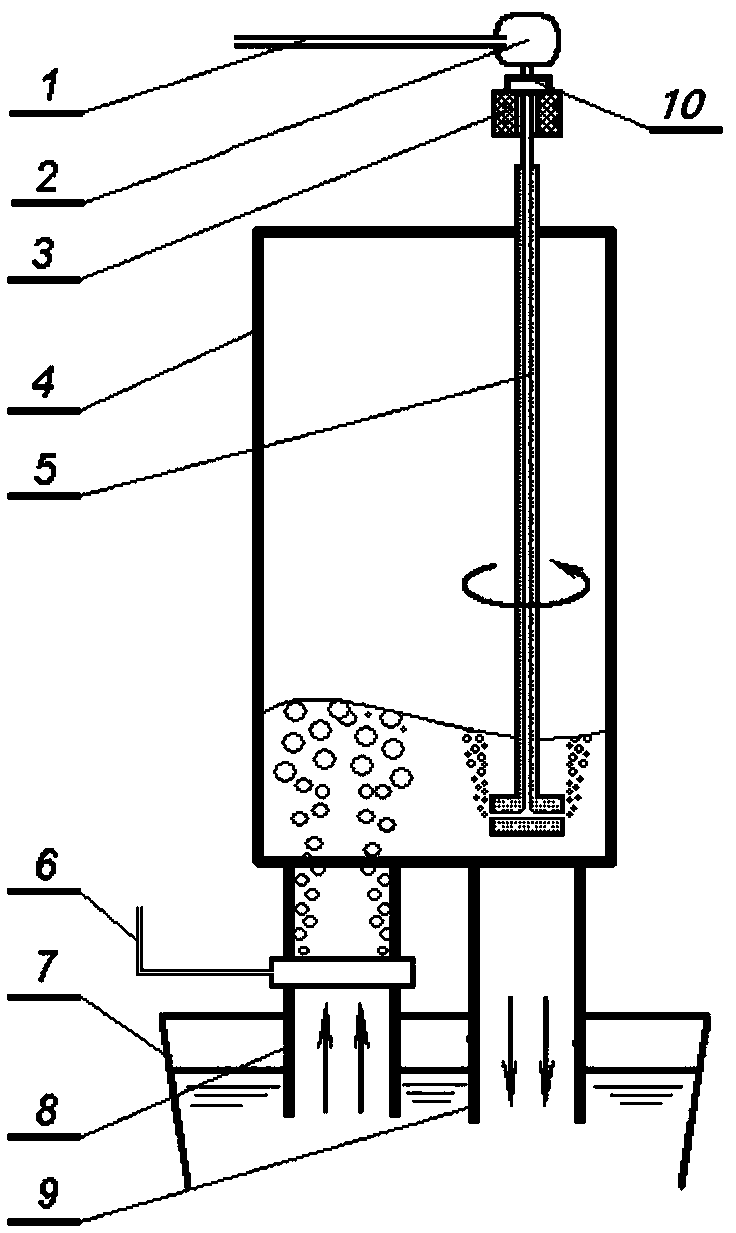

RH refining rotary powder-spraying desulfurization method

A powder spraying and refining technology, which is applied in the field of iron and steel metallurgy, can solve the problems of poor control of desulfurization reaction kinetic conditions, low powder utilization rate, and high production cost, and achieve the goal of improving kinetic conditions, increasing residence time, and improving purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The implementation plan is carried out on a 180t molten steel tank, the upper diameter of the molten steel tank is 3120mm, the bottom diameter is 2580mm, and the inner height is 4300mm. The diameter of the vacuum chamber is 1780mm, the height of the vacuum chamber is 6810mm, the diameter of the ascending pipe is 580mm, and the diameter of the descending pipe is the same as that of the ascending pipe. Lift the gas injection hole to 650mm from the bottom of the vacuum chamber, and the number of injection holes is 10.

[0020] The total length of the rotary powder spray gun is 7500mm, the length of the inverted T-shaped rotary head is 580mm, the diameter of the inverted T-shaped rotary head is 230mm, the diameter of the spray hole is 10mm, and the diameter of the hollow tube is 90mm.

[0021] The spray powder used is desulfurization powder, and its main components contain CaO78%, CaF 2 11%, CaCO 3 8%. The particle size is 0.02mm.

[0022] The desulfurization steps of m...

Embodiment 2

[0025] The implementation plan is carried out on a 180t molten steel tank, the upper diameter of the molten steel tank is 3150mm, the bottom diameter is 2600mm, and the inner height is 4300mm. The diameter of the vacuum chamber is 1750mm, the height of the vacuum chamber is 6850mm, the diameter of the ascending pipe is 580mm, and the diameter of the descending pipe is the same as that of the ascending pipe. The distance from the lifting gas injection hole to the bottom of the vacuum chamber is 680mm, and the number of injection holes is 12.

[0026] The total length of the rotary powder spray gun is 7120mm, the length of the inverted T-shaped rotary head is 600mm, the diameter of the inverted T-shaped rotary head is 280mm, the diameter of the spray hole is 11mm, and the diameter of the hollow tube is 100mm.

[0027] The spray powder used is desulfurization powder, and its main components contain CaO68%, CaF 2 13%, CaCO 3 10%. The particle size is 0.025mm.

[0028] The desu...

Embodiment 3

[0031] The implementation plan is carried out on a 180t molten steel tank, the upper diameter of the molten steel tank is 3150mm, the bottom diameter is 2600mm, and the inner height is 4300mm. The diameter of the vacuum chamber is 1750mm, the height of the vacuum chamber is 7100mm, the diameter of the ascending pipe is 580mm, and the diameter of the descending pipe is the same as that of the ascending pipe. The distance from the lifting gas injection hole to the bottom of the vacuum chamber is 680mm, and the number of injection holes is 12.

[0032] The total length of the rotary powder spray gun is 7800mm, the length of the inverted T-shaped rotary head is 580mm, the diameter of the stirring head is 280mm, the diameter of the spray hole is 10mm, and the diameter of the hollow tube is 110mm.

[0033] The spray powder used is desulfurization powder, and its main components contain CaO65%, CaF 2 15%, CaCO 3 13%. The particle size is 0.02mm.

[0034] The desulfurization steps o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com