Internal combustion engine with seat ring holes

A technology for internal combustion engines and seat rings, applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems of affecting combustion form, negative impact on thermal efficiency, and affecting combustion efficiency, so as to achieve the effect of optimizing gas exchange and optimizing engine efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

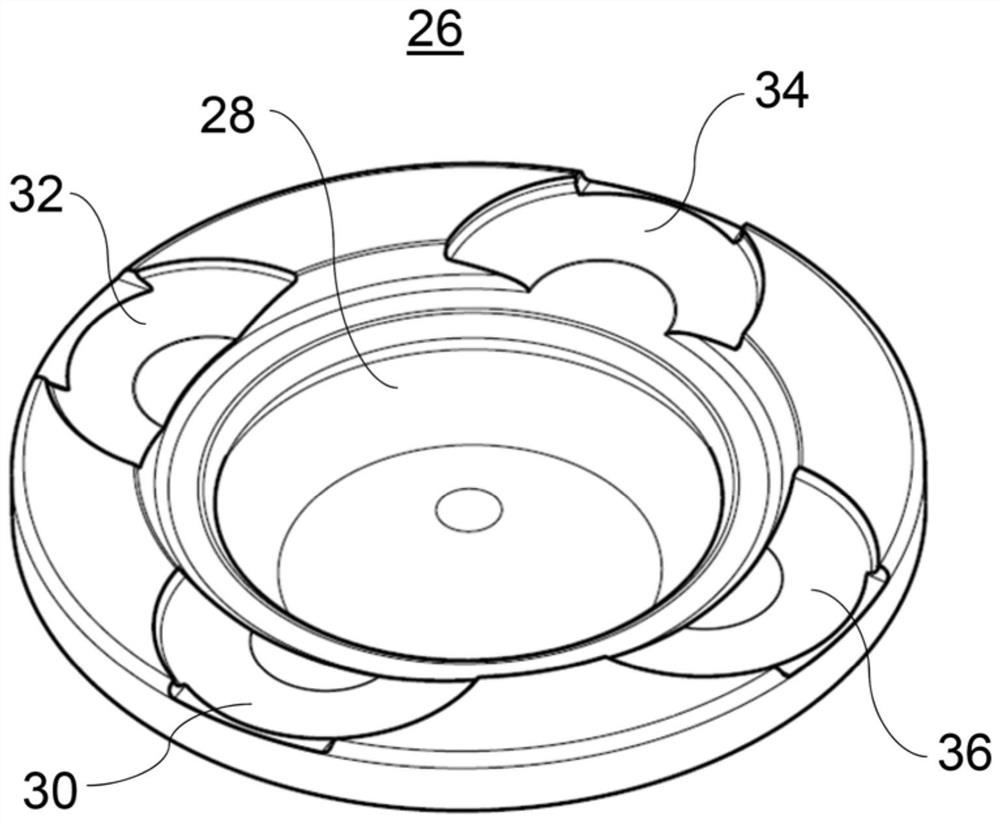

[0045] The embodiments shown in the figures are at least partly identical, such that similar or identical parts are identified with the same reference numerals, and for their explanation also reference is made to the description of the other embodiments or figures, in order to Avoid repetition.

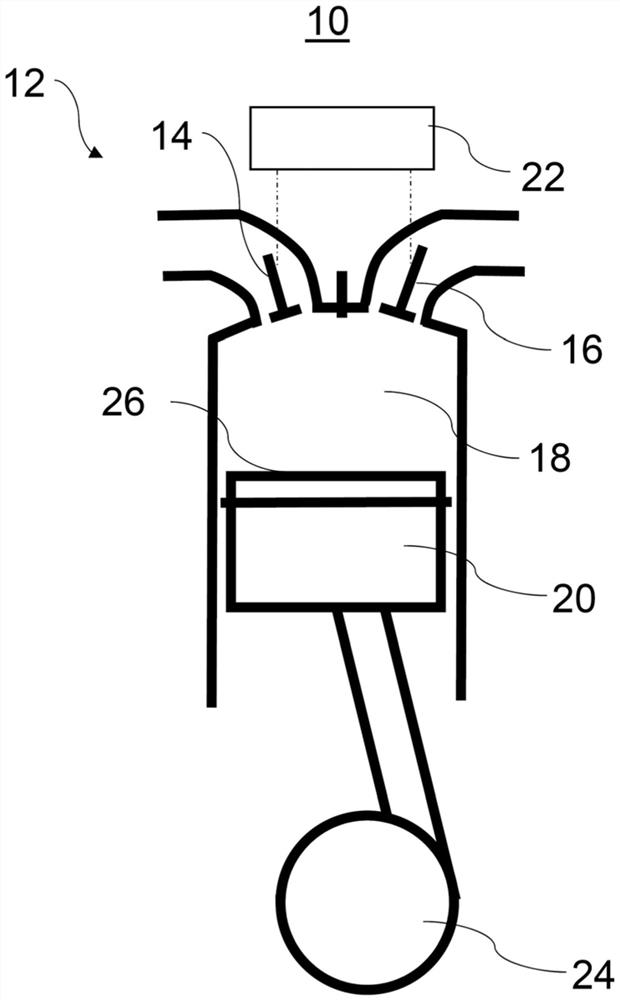

[0046] figure 1 One cylinder 12 of internal combustion engine 10 is shown. The internal combustion engine 10 is a four-stroke internal combustion engine, in particular a four-stroke diesel internal combustion engine or a four-stroke gasoline internal combustion engine. Preferably the internal combustion engine 10 is incorporated in a commercial vehicle, such as a van or a bus, for example for driving the commercial vehicle.

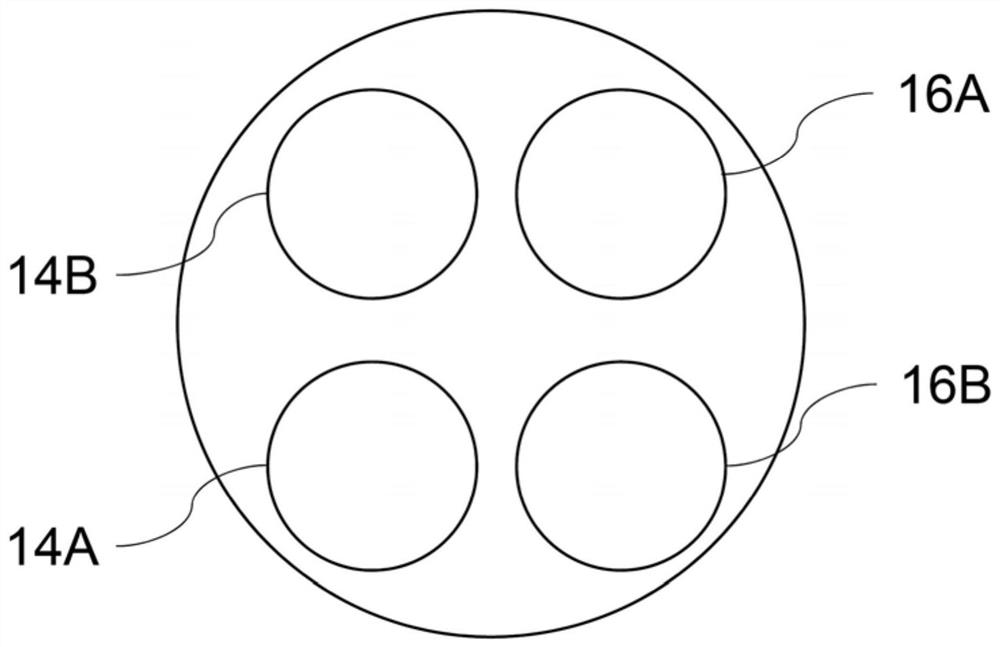

[0047] The cylinder 12 has a plurality of intake valves 14 (in figure 1 Only one is shown in ), multiple exhaust valves 16 (in figure 1 Only one is shown in ), a combustion chamber 18 and a piston 20 .

[0048] The intake valve 14 connects the combustion cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com